G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,413

- Solutions

- 3

- Reaction score

- 2,390

- Points

- 113

- Deals

- 1

Introduction

Introduction

I represent in this topic Lefetamine (Santenol) synthesis, which is to look quite simple. Also, this manual describes precursors syntheses of 2-phenylacetophenone (2) and Dimethylamine. Pay attention for safety measures with Dimethylamine, use good ventilated pull out probe and respirator.

Equipment and glassware:

- 250 mL Three neacked round-botton flask (RBF);

- 250 mL x 2 Flatbottomed flasks (FBF);

- Reflux condenser;

- Magnetic stirrer with heating surface;

- Retort stand and clamp for securing apparatus;

- Laboratory scale (0.05 — 200 g is suitable);

- 500 mL Separating funnel;

- Vacuum source;

- 100 mL x2; 50 mL x2 Beakers;

- Laboratory grade thermometer (0 °C to 200 °C) with flask adapter;

- Glass rod;

- 500 mL Buchner flask and funnel;

- Rubber stopper;

- x2 Glass tube;

- Plastic tube;

- Water bath;

- Distillation setup;

- Rotary evaporator — optional;

- pH indicator paper;

- Vacuum desiccator— optional.

Reagents:

- 10.4 g Benzoin (98 %);

- 25 mL Acetic acid (AcOH; 80 %);

- 3.2 g Zinc powder (Zn);

- ~50 mL 3% Hydrochloric acid (HCl) aq solution and ~50 mL 30% Hydrochloric acid (HCl) aq solution;

- ~1 L Distilled water;

- 10 g Dimethylformamide (DMF);

- ~50 g Sodium hydroxide (NaOH);

- 90 mL Methanol (MeOH);

- 3 g (0.11 mole) Aluminium (Al) foil;

- ~200 mg Hydrargyrum chloride (HgCl2);

- ~50 g Sodium chloride (NaCl);

- ~10 mL Isopropanol (IPA);

- ~200 mL Toluene.

N, N-Dimethyl-α-phenylbenzeneethanamine hydrochloride:

Boiling Point: N/A;

Melting Point: 218-219 °C;

Molecular Weight: 261.8 g/mole;

Density: N/A;

CAS Number: 14148-99-3.

Procedures

2-phenylacetophenoneIn a 250 mL round-bottom flask fitted with a reflux condenser, 10.4 g of benzoin (98%, Acros Organics) (1) was suspended in 25 mL 80% acetic acid (technical grade from the hardware store) and the mixture was heated with strong stirring. When the temperature of the mixture reached 115°C a clear solution was obtained. 3.2 g Of zinc powder was activated by immersing in a 3% HCl solution for 15 minutes. The dilute acid was decanted and washed with an aliquot of distilled water, and the zinc powder was added portionwise to the hot, strongly stirring solution of benzoin (1), care being taken that the resulting frothing was kept under control. After this, the temperature was raised, so the mixture was boiling. After one hour all zinc was consumed and an oily precipitate was noted when the stirring was temporarily halted.

Activating the Zn powder before this reduction makes a lot of difference. In my hands, the reaction was finished in less than an hour, all zinc powder being consumed.

The contents of the flask were poured into 100 ml hot water in a beaker, and there was observed the formation of an oil layer on the bottom. After cooling overnight, the oil solidified to white crystals of 2-phenylacetophenone (2) with only a faint odor, distinctly different from the almond-like odor of benzoin. Crystals were filtered and washed with a small amount of cold water. After recrystallizing from methanol (4 mL per 1 g), there was obtained 7.35 g desoxybenzoin (2-phenylacetophenone) (2), which corresponds to a 76% total yield.

The contents of the flask were poured into 100 ml hot water in a beaker, and there was observed the formation of an oil layer on the bottom. After cooling overnight, the oil solidified to white crystals of 2-phenylacetophenone (2) with only a faint odor, distinctly different from the almond-like odor of benzoin. Crystals were filtered and washed with a small amount of cold water. After recrystallizing from methanol (4 mL per 1 g), there was obtained 7.35 g desoxybenzoin (2-phenylacetophenone) (2), which corresponds to a 76% total yield.

Dimethylamine

In a flat-bottomed flask (FBF) was placed 10 g dimethylformamide (DMF) and 40 grams of a 30% NaOH solution was added, upon which the solution turned a yellow colour. The FBF was closed with a rubber stopper fitted with a glass tube, plastic tubing attached led from this tube to another glass tube immersed in 90 ml methanol in another FBF. The FBF containing the DMF/NaOH mixture was placed on a hotplate and the temperature was gradually increased until gas generation started (only gentle heating was needed, around 50°C). All dimethylamine dissolved readily in the methanol and there was no odour discomfort arising from this. When gas evolution ceases, the yellow colour of the original mixture suddenly faded and became clear. At this point, the alkaline hydrolysis of DMF has finished, so beware of suck back that will occur if one is careless! After weighing the dimethylamine in methanol solution, it was observed that the weight had increased by 4.75 g (~77% yield or about 0.1 mole, ignoring the fact that the gas was not dried).

N,N-Dimethyl-α-phenylbenzeneethanamine (Lefetamine) hydrochloride

The latter solution was placed in a 250 mL RBF fitted with a reflux condenser, and a solution of 5.9 grams (0.03 mol) desoxybenzoin (2-phenylacetophenone) in 50 mL methanol was added. The resulting solution was stirred for 2 hours (to ensure complete formation of the enamine), after which 3 g (0.11 mole) shredded 18 µ kitchen Al foil "nuggets" was added, followed with a dash (tip of the knife really) of HgCl2. The flask was fitted with its reflux condenser, and strong stirring was performed throughout the entire reaction. The first half hour the reaction proceeded sluggishly, although all clear signs of amalgamating were present. Gentle heat was applied with a water bath for 5 minutes, which caused a moderately exothermic reaction to kick in, which continued until most Al was consumed (another 30 min). It was left stirring overnight.

The latter solution was placed in a 250 mL RBF fitted with a reflux condenser, and a solution of 5.9 grams (0.03 mol) desoxybenzoin (2-phenylacetophenone) in 50 mL methanol was added. The resulting solution was stirred for 2 hours (to ensure complete formation of the enamine), after which 3 g (0.11 mole) shredded 18 µ kitchen Al foil "nuggets" was added, followed with a dash (tip of the knife really) of HgCl2. The flask was fitted with its reflux condenser, and strong stirring was performed throughout the entire reaction. The first half hour the reaction proceeded sluggishly, although all clear signs of amalgamating were present. Gentle heat was applied with a water bath for 5 minutes, which caused a moderately exothermic reaction to kick in, which continued until most Al was consumed (another 30 min). It was left stirring overnight.

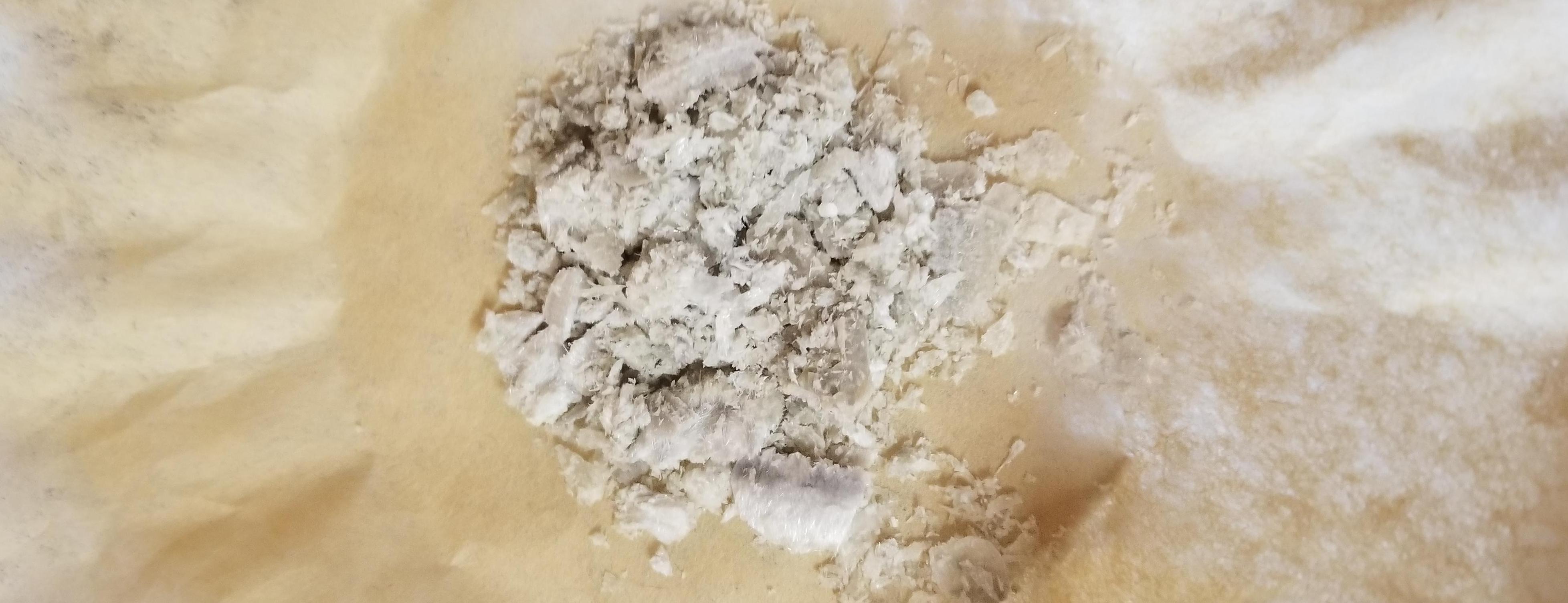

The next morning the flask was set up for distillation, part of the methanol was distilled off, and after cooling the solution was basified with concentrated NaOH aq solution. This was extracted twice with toluene, the pooled extracts washed 3 x with a large amount of water and 2x with brine. After evaporation of the solvent, 2.35 g of a yellowish brown oil with a sharp smell and basic properties remained. On diluting the oil with 4 ml isopropanol, followed by neutralization to 7 pHs by dropwise addition of 30% HCl, a Lefetamine precipitate was formed. Lefetamine precipitate was filtered and washed with a small amount of cold IPA and dried in vacuum desiccator.

Last edited by a moderator: