- Joined

- Dec 27, 2022

- Messages

- 30

- Reaction score

- 75

- Points

- 18

Hope ya'll enjoy!

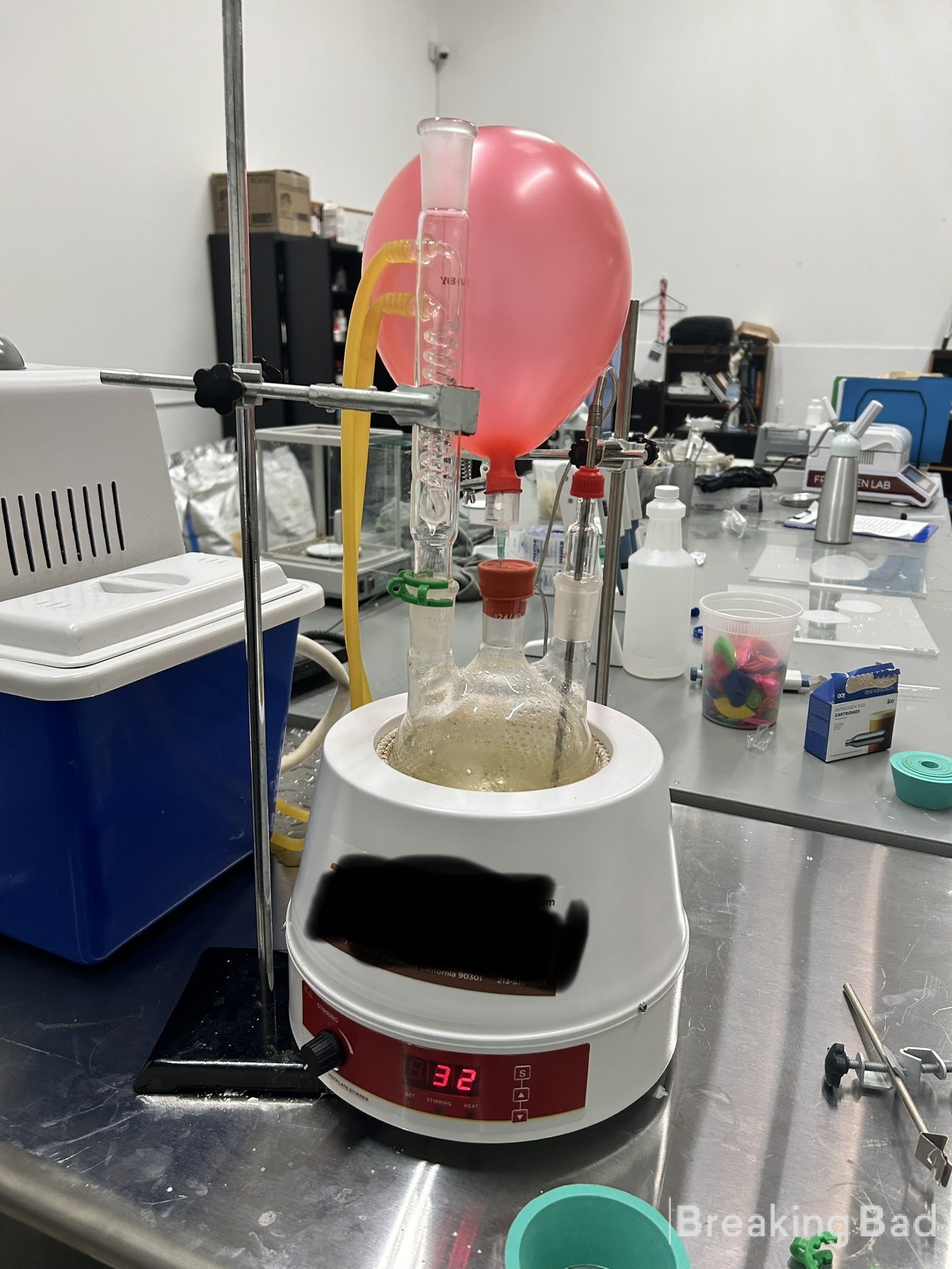

1. A medium sized magnetic stir bar was inserted into a 500 mL RBG flask. 18 g of phenylhydrazine HCl was dissolved in 250 ml of deionized water in a 500 mL 3 neck 24/40 joint RBF, which is put onto a heating mantel that acts as a magnetic stirrer. Neck 1 had a rubber septum, neck 2 had a thermometer, in a glass 24/20 adapter, and was connected to the heating mantel. And neck 3 had a reflux condenser connected to a water circulator.

2. 4 balloons were charged with nitrogen, attached to the end of a 20 mL syringe (with no plug). An 18 gauge needle was attached to the syringe and the syringe set up was inserted into a solid piece of rubber for later use.

3. The RBF was charged with nitrogen by inserting the syringe (with a nitrogen balloon at the end) into neck 1. The heating mantel was set to 32 'C. and the magnetic stir bar was set to medium-high stirring level.

4. A 10 mL syringe was filled with 7.2 mL concentrated sulfuric acid and a 18 gauge needle was attached to the syringe. The syringe with sulfuric acid was inserted into the rubber septum on neck 1. The sulfuric acid was slowly added to the suspension, under a nitrogen environment, over 10 minutes while maintaining the temperature below 40'C. .

5. The solution (light orange color) is heated to 37'C and stirred for additional 10 mins.

6. A solution of 25 g of 4-(N,N-dimethylamino)butanal diethyl acetal in 90 mL of acetonitrile was prepared in a 250 mL beaker.

7. The rubber septum on neck 1 was detached and a 100 mL addition funnel was added. The 4-(N,N-dimethylamino) butanal diethyl acetalsolutionin acetonitrile was added to the addition funnel. The rubber septum, with the nitrogen balloon still attached, was inserted on top of the addition funnel.

8. Once step 5 was completed, After 10 mins, the 4-(N,N-dimethylamino) butanal diethyl acetalsolutionin acetonitrile solution was added dropwise over 60 mins, while temperature is maintained at 37'C. After addition, addition funnel is rinsed with acetonitrile(about 30ml) and added dropwise to the reactor.

9. The contents were stirred for 4 hrs while temperature is maintained at 40'C.

10. To the acidic solution in the RBF, 100ml of NaOH solution (4M) was added dropwise while maintaining the temperature at 20~25'C. The RBF flask was periodically put into a cold bath if the temperature reached 25'C. The pH of the solution was 11 after the NaOH was added and the suspension was milky.

.

11. The suspension in the RBF suspension is extracted with 3* 200 DCM

12, The organic layers are combined and put into a vacuum oven at 30 'C with a negative pressure of -30 mm hg. The final product was left in the vacuum oven for 48 hours, in order to ensure all solvent is evaporated.

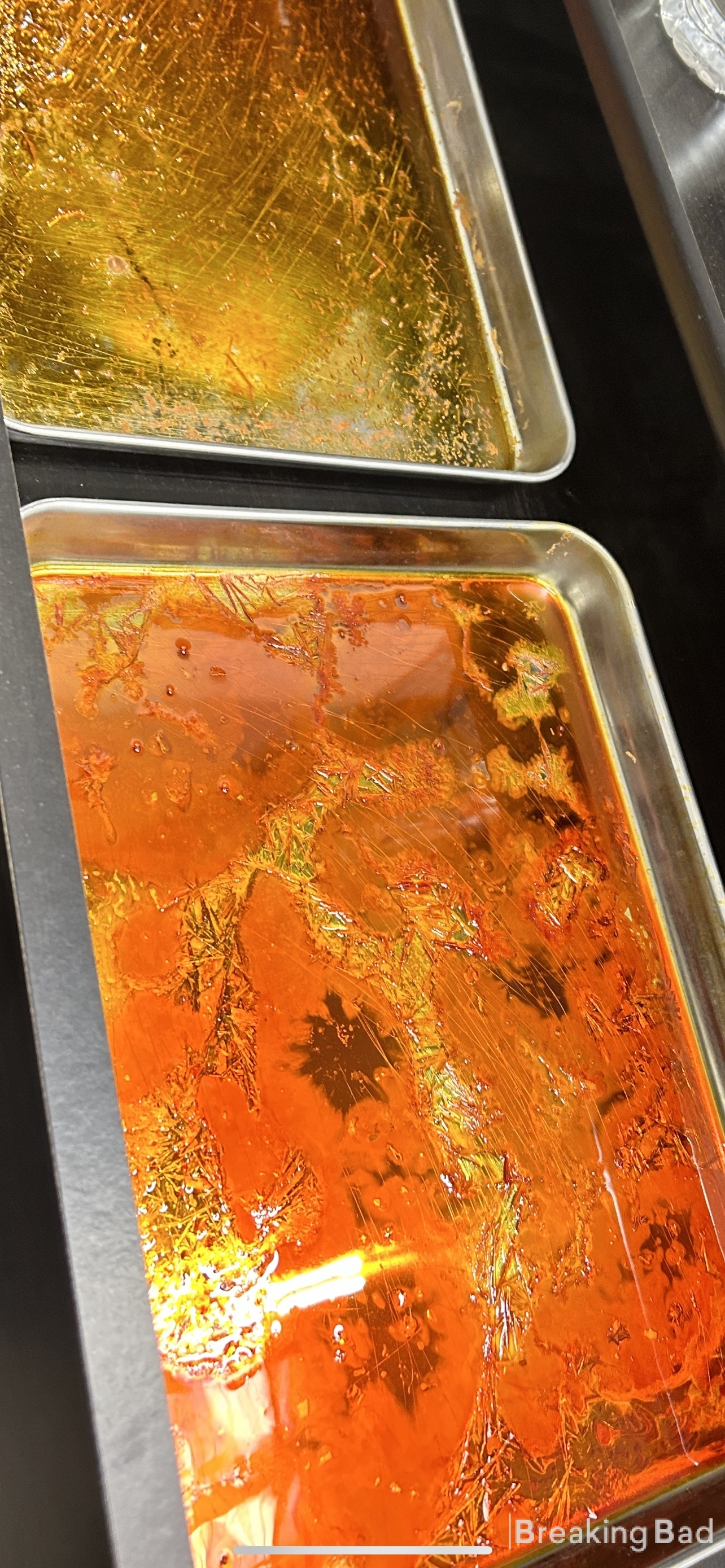

13. After 48 hours, the final product formed light orange crystals and some light orange residue.

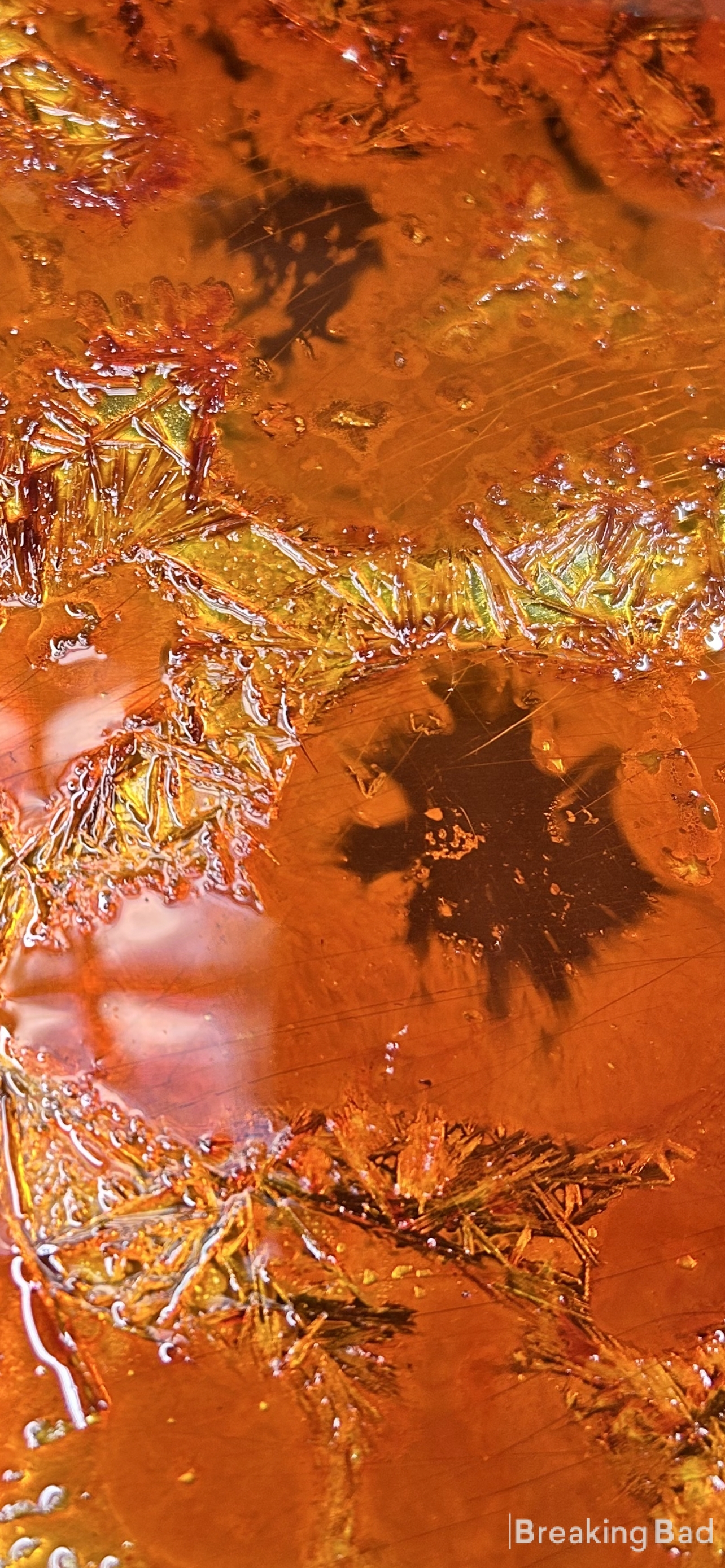

14. The crude freebase was dissolved in acetone (200 mL) and poured through a pad of silica (230–400 mesh, 100 g). The pad was eluted with acetone/MeOH (9:1, 2 L). The combined filtrates were put back into the vacuum oven at 30 'C for 24 hours. 30 'C. The final product had a mass of 15.45 g of purified N,N DMT freebase as a concentrated to provide 15.45 g of purified N,N DMT freebase (56.8% yield) as a yellow-reddish oil with yellow crystals that formed around the oil.

15. Melting point was 45-47 'C, which corresponds to a combination of DMT polymorph I and II.

Isolated N,N DMT crystals!

1. A medium sized magnetic stir bar was inserted into a 500 mL RBG flask. 18 g of phenylhydrazine HCl was dissolved in 250 ml of deionized water in a 500 mL 3 neck 24/40 joint RBF, which is put onto a heating mantel that acts as a magnetic stirrer. Neck 1 had a rubber septum, neck 2 had a thermometer, in a glass 24/20 adapter, and was connected to the heating mantel. And neck 3 had a reflux condenser connected to a water circulator.

2. 4 balloons were charged with nitrogen, attached to the end of a 20 mL syringe (with no plug). An 18 gauge needle was attached to the syringe and the syringe set up was inserted into a solid piece of rubber for later use.

3. The RBF was charged with nitrogen by inserting the syringe (with a nitrogen balloon at the end) into neck 1. The heating mantel was set to 32 'C. and the magnetic stir bar was set to medium-high stirring level.

4. A 10 mL syringe was filled with 7.2 mL concentrated sulfuric acid and a 18 gauge needle was attached to the syringe. The syringe with sulfuric acid was inserted into the rubber septum on neck 1. The sulfuric acid was slowly added to the suspension, under a nitrogen environment, over 10 minutes while maintaining the temperature below 40'C. .

5. The solution (light orange color) is heated to 37'C and stirred for additional 10 mins.

6. A solution of 25 g of 4-(N,N-dimethylamino)butanal diethyl acetal in 90 mL of acetonitrile was prepared in a 250 mL beaker.

7. The rubber septum on neck 1 was detached and a 100 mL addition funnel was added. The 4-(N,N-dimethylamino) butanal diethyl acetalsolutionin acetonitrile was added to the addition funnel. The rubber septum, with the nitrogen balloon still attached, was inserted on top of the addition funnel.

8. Once step 5 was completed, After 10 mins, the 4-(N,N-dimethylamino) butanal diethyl acetalsolutionin acetonitrile solution was added dropwise over 60 mins, while temperature is maintained at 37'C. After addition, addition funnel is rinsed with acetonitrile(about 30ml) and added dropwise to the reactor.

9. The contents were stirred for 4 hrs while temperature is maintained at 40'C.

10. To the acidic solution in the RBF, 100ml of NaOH solution (4M) was added dropwise while maintaining the temperature at 20~25'C. The RBF flask was periodically put into a cold bath if the temperature reached 25'C. The pH of the solution was 11 after the NaOH was added and the suspension was milky.

.

11. The suspension in the RBF suspension is extracted with 3* 200 DCM

12, The organic layers are combined and put into a vacuum oven at 30 'C with a negative pressure of -30 mm hg. The final product was left in the vacuum oven for 48 hours, in order to ensure all solvent is evaporated.

13. After 48 hours, the final product formed light orange crystals and some light orange residue.

14. The crude freebase was dissolved in acetone (200 mL) and poured through a pad of silica (230–400 mesh, 100 g). The pad was eluted with acetone/MeOH (9:1, 2 L). The combined filtrates were put back into the vacuum oven at 30 'C for 24 hours. 30 'C. The final product had a mass of 15.45 g of purified N,N DMT freebase as a concentrated to provide 15.45 g of purified N,N DMT freebase (56.8% yield) as a yellow-reddish oil with yellow crystals that formed around the oil.

15. Melting point was 45-47 'C, which corresponds to a combination of DMT polymorph I and II.

Isolated N,N DMT crystals!

Last edited by a moderator: