G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,596

- Solutions

- 3

- Reaction score

- 2,623

- Points

- 113

- Deals

- 1

Introduction

This method will produce pure Bufotenine from Anadenanthera colubrina seeds, using a minimal amount of steps and non-toxic reagents. The manual was developed based on an other two threads and combining the most useful methods, but it adds some tweaks and new ways and therefore will finally lead to a solid, crystaline product. In 3 steps all compounds with lower polarity will be removed, then all fats will be divided from alkaloids, then all more polar alkaloids will be removed to give pure Bufotenine. Yield ~ 1-3 %.

Boiling Point: 320 °C at 760 mm Hg;

Melting Point: 132 °C (base);

Molecular Weight: 204.27 g/mole;

Density: 1.178 g/mL;

CAS Number: 487-93-4.

Bufotenin is also present in the skin secretion of three arboreal hylid frogs of the genus Osteocephalus (Osteocephalus taurinus, Osteocephalus oophagus, and Osteocephalus langsdorfii) from the Amazon and Atlantic rain forests. The acute toxicity (LD50) of bufotenin in rodents has been estimated at 200 to 300 mg/kg. Death occurs by respiratory arrest. In April 2017, a South Korean man died of bufotenin poisoning after consuming toads that had been mistaken for edible Asian bullfrogs, while in Dec. 2019, five Taiwanese men became ill and one man died after eating Central Formosa toads that they mistook for frogs. DON'T EAT FROGS!

Reagent and materials

Reagent and materials

- 100 g of Anadenanthera colubrina seeds ("Vilca", "Cebil" ) [1 Seed ~ 180 mg, 100 g ~ 555 seeds];

- 1200 mL dry Acetone (put 50 g of anhydrous MgSO4 or Na2SO4 into Acetone and let it sit 1 night);

- 1000 mL Naphtha (preferred: Hexane/Heptane isomers, "C6-C7-Alkanes", boiling Range 60 - 80 °C);

- 150 mL Ethyl Acetate (if you cant get your hands on, you can use Xylene instead. See solubility table for adjusted volume then);

- 400 mL of FASA, Fumaric Acid can be replaced with Citric Acid from a Grovery (prepared from your 1200 mL dry Acetone, according to this source 0,92 g Fumaric Acids dissolves in 100 mL at 20 °C and 1,7 g at 50 °C);

- 1 package of soda/Na2CO3 (you will only need some gramm, but 1 package should be less than 2 €);

- Cheap kitchen grinding machine like this - a coffee grinder may also work;

Procedure

1. Preparation of the seedsPrepare your dry Acetone + FASA before starting this procedure to save time. Lay out 100 g of your seeds in a pan and turn the pan on the hottest setting. After the first seed pops open, turn the heat down to the lowest setting where you still notice more seeds popping. This is the sound of pressure building up and breaking apart the seeds, while volatile components leave the seeds. The smell is like tasty caramelized nuts, but dont forget to turn the heat to the lowest possible setting, or it will smell burned and all Alkaloids get destroyed. When you dont hear any more seeds popping, this step is completed.

This step will remove ~ 6 % of unwanted compounds aka. fats and/or water.

Important: If fumes visibly arise then you already know that it is too high, as the release of those contaminations wont form visible fumes.

Important: place a cover on your pan, but dont close it completely or else the heat will quickly rise up inside of your pan and still destroy your seeds on the lowest heat (depending on your stove, again)

This step will remove ~ 6 % of unwanted compounds aka. fats and/or water.

Important: If fumes visibly arise then you already know that it is too high, as the release of those contaminations wont form visible fumes.

Important: place a cover on your pan, but dont close it completely or else the heat will quickly rise up inside of your pan and still destroy your seeds on the lowest heat (depending on your stove, again)

Picture of the seeds before (left) and after (right) cracking at low heat.

2. Freebasing the AlkaloidsNow place your popped seeds in the milling machine and create a fine dust. Then add 25 g of sodium carbonate (Na2CO3, but not NaHCO3 which is too weak) aka. Soda (1:4 to original seed weight) and mix both to a homogeneous powder. Now add water to the dry mass until you reach a dough-like consistency. While doing this a strong freebase-smell will develop.

Optimal ratio: 1,5 mL : 1 g original seed weight, which means 150 mL on 100 g Seeds.

Important: If you use Hydroxides like Lime (Ca(OH)2) or Sodium Hydroxide (NaOH) it may destroy the Bufotenine at high pH ranges from 12 onwards due to the irreversible oxidation of the 5-OH-Group to an Enone. Carbonate can only raise the pH to ~ 11 and should be used without exceptions.

Important: If you use Hydroxides like Lime (Ca(OH)2) or Sodium Hydroxide (NaOH) it may destroy the Bufotenine at high pH ranges from 12 onwards due to the irreversible oxidation of the 5-OH-Group to an Enone. Carbonate can only raise the pH to ~ 11 and should be used without exceptions.

Picture of the grinded seeds (left) and the mixture with Na2CO3 (right).

Let this mixture sit for 60 minutes and mix it from time to time. Afterwards the mixture needs to be dried. Either put it in the oven at 75 °C and turn on maximum ventilation or lay it out in a pan, turn heat on a LOW setting and use a fan from the side - this is much faster than the oven method. But heavily check temperature to not destroy any actives. Fumes should not arise, these indicate decomposition. The paste will shrink in size and form blocks. Crack them up to increase surface area and accelerate water removal. At the end use the milling machine again to form a fine powder again - greatly improves the extraction step!

Important: Note the weight of your dry mixture so you know at the next step when you have removed all the water.

Important: Note the weight of your dry mixture so you know at the next step when you have removed all the water.

Picture of the seed paste (left) and the seed paste while drying in a pan (right).

3. Defatting the Alkaloids with NaphthaThis step is used to remove all the unwanted alkaloids aka fats that are less polar than Bufotenine. Place your freebased seed/soda mix in a container and add 150 mL of Naphtha. Boil the mixture at 60-65 °C for 5 minutes in the Naphtha while preferably stirring - no need to be exact with temperature, just make sure that it is boiling. Wait for the seed powder to sediment down to the bottom, also shake the vial gently to make the paste form a solid packed layer. If the layer is very dense you can decant the Naphtha without spilling over any seed paste. Repeat 3x, better be safe, Naphtha is cheap and this step is essential.

This defat step will remove ~ 8 % of unwanted compounds aka. fats.

In theory this step would contain all the DMT or 5-MeO-DMT from the seeds. By applying FASA to the Naphtha no clouding can be observed. It seems either it evaporated at step 1 or there is indeed nearly none of these in the seeds. You may check yourself.

Important: As you may not fully prevent spilling over seed material you may filter the Naphtha through a sneeze tissue while decanting.

This defat step will remove ~ 8 % of unwanted compounds aka. fats.

In theory this step would contain all the DMT or 5-MeO-DMT from the seeds. By applying FASA to the Naphtha no clouding can be observed. It seems either it evaporated at step 1 or there is indeed nearly none of these in the seeds. You may check yourself.

Important: As you may not fully prevent spilling over seed material you may filter the Naphtha through a sneeze tissue while decanting.

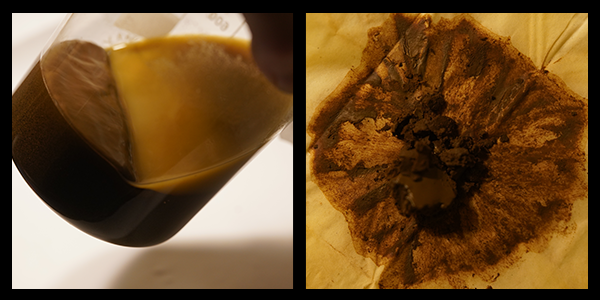

Picture of the seed mixture while defatting with Naphtha (left). Clearly watch the dense package of the seeds, which will not spill over. Shake the vial smoothly to achieve this density. Picture of the setup to recover spilled over material (right).

Important: After this step the seed powder is basically the same as the traditional Yopo / Cebil / Vilca Snuff used by south american shamans for their visionary effects. I strongly recommend NOT using them as a snuff if you used an electric milling machine, as this produces particles ranging down to extremely fine dust which WILL also get dragged into your lungs when insufflating. As they are not soluble in your lungs it may cause the same unhealthy effects like any other fine dust sources.

4. Extracting the Alkaloids with Acetone

Now the target Alkaloids are extracted from the freebased seed powder. Place them in the same container from step 3 again and pour 300 mL (to 100 g seeds) of your dry Acetone on the powder. Boil the seeds at ~ 60 °C for 10 minutes in the Acetone while preferably stirring - no need to be exact with temperature, just make sure that it is boiling. Wait for the seed powder to sediment down to the bottom, decant the Acetone and repeat 2x times with fresh solvent.

Again, shake the vial gently before decanting, this will solidity the mass and make life much easier.

This extraction step dissolves 8 % of alkaloids and fats from the seeds (Bufotenine will be ~ 1-2 % of these).

Important: Close the container while heating, but dont let pressure build up. You may use cling film and a rubber band to prevent air (and therefore water) to get inside of your dried acetone. Huge water take-up would reduce the yield later on.

This extraction step dissolves 8 % of alkaloids and fats from the seeds (Bufotenine will be ~ 1-2 % of these).

Important: Close the container while heating, but dont let pressure build up. You may use cling film and a rubber band to prevent air (and therefore water) to get inside of your dried acetone. Huge water take-up would reduce the yield later on.

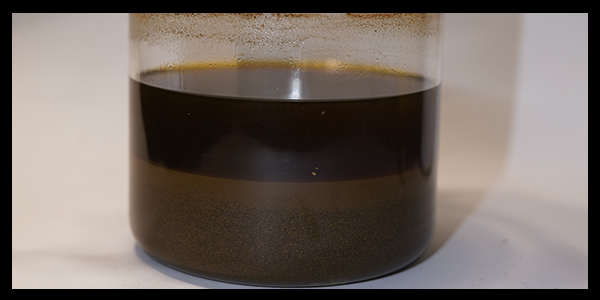

Picture of the seed mixture while extracting with Acetone. You can see the solid material settled down for easy decanting.

Now to separate the Alkaloids from the other fats FASA will be added to the solution. By assuming that the Alkaloid content of the seeds is around 1-4 % (reports of 13 % just sound unrealistic) you can expect 3 g of Fumaric Acid to be more than enough to fully precipitate every last Alkaloid. Add 300 mL from the 400 mL of FASA to your combined Acetone extracts.

This precipitation method will separate 3,75 g of Alkaloid Fumarates from the Acetone Extract, which equals equals ~ 2,4 - 2,9 % of Alkaloids extracted, depending on being Mono- or Disalt Fumarates. (Bufotenine will be ~ 1-2 % of these)

This precipitation method will separate 3,75 g of Alkaloid Fumarates from the Acetone Extract, which equals equals ~ 2,4 - 2,9 % of Alkaloids extracted, depending on being Mono- or Disalt Fumarates. (Bufotenine will be ~ 1-2 % of these)

GIF showing the addition of FASA to the Acetone Extracts.

[/url]

[/url]

Important: Even though the clouding is very intense it takes many hours for full phase separation and crystalization of the Alkaloid-Fumarates. So close the container and let the solution sit over night (at the stage of being fumarate salts the alkaloids have a very long shelf life just like any other fumarate alkaloids). Pay attention that even after full crystalization the solution will not turn clear, so dont wait for this moment. To be safe, decant it and keep the liquid to check if more precipitation is forming while proceeding the next steps with the Fumarate-crystals.

Important: Fumaric Acid + Acetone can be replaced by Citric Acid + Acetone, as Citric Acid can be bought from any grocery. Instead it will form a blob then, which looks like this and will settle down immediately instead of having to wait.

Important: Fumaric Acid + Acetone can be replaced by Citric Acid + Acetone, as Citric Acid can be bought from any grocery. Instead it will form a blob then, which looks like this and will settle down immediately instead of having to wait.

But it will contain a lot of Acetone, which will slowly drip out. Wait for 2 h while tilting the blob in a closed vessle, so Acetone can rinse out, while no water can stick to the Alkaloid-Citrates - they are quite hygroscopic in contrast to Fumarates.

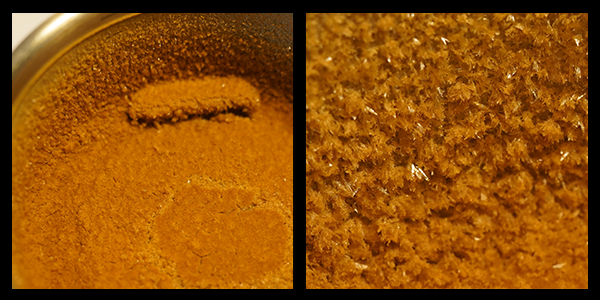

Picture of the Alkaloid Fumarates after 10 h of precipitation (left) and in close-up (right). The big cucumber strucure is a stirring bar, in case you wondered.

Important: Dont rinse the Alkaloid Fumarates with Acetone. This will break up the crystals partially and you cant decant the Acetone without loosing too many material. Still, it is not even needed for purity.

5. Extracting Bufotenine from the Alkaloid mixture

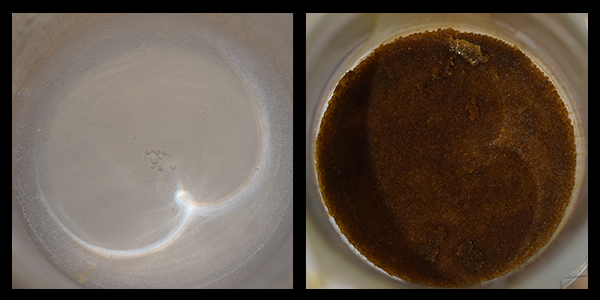

Dissolve your Alkaloid-Fumarates in 25 mL of hot water. Discard what does not dissolve. Then create a solution of soda/Na2CO3 in 25 mL hot water, use a ratio of 0,5:1 Na2CO3:Alkaloid-Fumarates. You should not use excessive Na2CO3, as Bufotenine may dissolve in water if you used too much Na2CO3. Decant to get rid of any non-dissolved soda. Slowly pour the Alkaloid-Fumarate solution into the soda solution. You should use a vial for the soda solution that you can use for heating in the next step.

You will recognize brown clouds of freebase Alkaloids form and settle to the bottom after a few seconds. Upon stirring they form a big clumpy ball.

5. Extracting Bufotenine from the Alkaloid mixture

Dissolve your Alkaloid-Fumarates in 25 mL of hot water. Discard what does not dissolve. Then create a solution of soda/Na2CO3 in 25 mL hot water, use a ratio of 0,5:1 Na2CO3:Alkaloid-Fumarates. You should not use excessive Na2CO3, as Bufotenine may dissolve in water if you used too much Na2CO3. Decant to get rid of any non-dissolved soda. Slowly pour the Alkaloid-Fumarate solution into the soda solution. You should use a vial for the soda solution that you can use for heating in the next step.

You will recognize brown clouds of freebase Alkaloids form and settle to the bottom after a few seconds. Upon stirring they form a big clumpy ball.

GIF of the addition of Alkaloid Fumarates into saturated Na2CO3-solution. At the end you can see the brown freebase clump that is rolled in circles through the glass vial.

Now the Alkaloids of the seeds are reverted back to their Freebase form and can be extracted with an unpolar solvent. Decant the water, all the Alkaloids are present in the brown sticky blob. Dont worry if the water is still light tan, it still does not contain any Bufotenine. Create a 600 mL solution of 1:3 Ethyl Acetate:Naphtha (125:475 mL EA:Na) and pour 100 mL of this mixture over your freebase blob. Heat it to boiling while stirring. Now the blob will form a round ball while being stirred through your vessel. If the defat step was very thoroughly, then it should solidify to a hard ball after ~ 1 minute, if not it may stay sticky. This wont be a problem, if so just continue as normal. But if it solidifies you will need to stop stirring and crush it into fine dust. Heat + stirr the mass for 5 minutes at boiling temperature. If you have dusty material, wait for it to sediment to the bottom, if not just decant directly into a new container. Repeat with fresh 100 mL EA:Naphtha mixture. Based on the solubility of Bufotenine in this mixture you would only need 300 mL to dissolve 2 g (assuming a 2 % max in 100 g seeds), but you will need a little more to get everything out of the Alkaloid mix. For this reason only combine the first 3 pulls and everything besides combine in a separate vessel, this will ensure that most of the Bufotenine will be dissolved in a highly saturated solution. The powder / goo will shrink and turn darker within this proces, stop when the powder / goo does not loose weight anymore. A brown or even black solid residue will be left at the end.

Solubility of Bufotenine / 5-OH-DMT in 1:3 EA:Naphtha:

70 °C = 7,6 g/L or 760 mg/100 mL

20 °C = 3,6 g/L or 360 mg/100 mL

- 20 °C = 3,5 g/L or 350 mg/100 mL

Comment on this solvent system:70 °C = 7,6 g/L or 760 mg/100 mL

20 °C = 3,6 g/L or 360 mg/100 mL

- 20 °C = 3,5 g/L or 350 mg/100 mL

The solubility is quite low overall, but its the only option to divide it from more polar Alkaloids. Bizarrely see the solubility does not drop further when switching from ambient temperature to a freezer. Therefore one can just "fridge precipitate", as freezing it at - 20 °C wont have any benefits.

Old manuals used 1:4 Acetone:Naphtha. This works worse for separation of Alkaloids and will never produce a solid product. Dont use it, the main reason why this manual is finally successful is the usage of this solvent mix. Also in case something goes wrong 1:4 Acetone:Naphtha cant be used for liquid-liquid extractions, while 1:3 EA:Naphtha can be. You may even try to extract Bufotenine traces from the water in which you poured the Alkaloid-Fumarates, which was decanted off afterwards, to see if there are any more goodies. I did not check.

Important: Always close the container while boiling the Alkaloids. EA and Naphtha have different boiling points, so you dont want vapor to escape, which would cause unpredictable change the solvent composition and therefore unknown solubility behaviour.

I would now instead suggest to use pure Xylene for this step. It is even more effective for this purpose and in many countries more accessible than Ethyl Acetate.

Old manuals used 1:4 Acetone:Naphtha. This works worse for separation of Alkaloids and will never produce a solid product. Dont use it, the main reason why this manual is finally successful is the usage of this solvent mix. Also in case something goes wrong 1:4 Acetone:Naphtha cant be used for liquid-liquid extractions, while 1:3 EA:Naphtha can be. You may even try to extract Bufotenine traces from the water in which you poured the Alkaloid-Fumarates, which was decanted off afterwards, to see if there are any more goodies. I did not check.

Important: Always close the container while boiling the Alkaloids. EA and Naphtha have different boiling points, so you dont want vapor to escape, which would cause unpredictable change the solvent composition and therefore unknown solubility behaviour.

I would now instead suggest to use pure Xylene for this step. It is even more effective for this purpose and in many countries more accessible than Ethyl Acetate.

Xylene

Boiling = 48 g/L = 4,8 g in 100 mL

- 20 °C = 15,3 g/L = 1,53 g in 100 mL

Boiling = 48 g/L = 4,8 g in 100 mL

- 20 °C = 15,3 g/L = 1,53 g in 100 mL

Xylene is the only non-mixture solvent to form crystals. The only downside:

Solubility at - 20 °C is still high, so you will loose some or you have to evaporate after decanting. Also evaporation takes long. If using heat, then definetly watch your mixture all the time, as Bufotenin may vaporize away if all the Xylene is gone and you dont stop.Picture of the sticky Freebase Blob after decanting the water (left) and after crushing the solidified freebase blob to fine dust (right). Dont worry if it not solidifies, then the defat step may have not been 100 % efficient. Proceed as normal.

Close all the 3 containers with a plastic foil (or whatever you like) and place them in a fridge. It seems like temperatures of a freezer (-20 °C) dont decrease solubility of Bufotenine further, quite strange. Therefore you can just leave it in a fridge. After ~ 5 h you will see yellow to white either amorph or even crystaline solids on the bottom. Now decant the solvent and leave it on a plain big surface for evaporation, which will give some more Bufotenine, which may have a little lower purity. You can redissolve this second fraction in more 1:3 Ethyl Acetate:Naphtha and also do a fridge precipitation on them.

Combined collected material = 1,13 g Freebase Bufotenine (1,13 % yield)

[later extraction: 2,6 g from 75 g Seeds = 3.4 % yield!].

Congratulations: You got yourself some solid pure freebase Bufotenine!

Combined collected material = 1,13 g Freebase Bufotenine (1,13 % yield)

[later extraction: 2,6 g from 75 g Seeds = 3.4 % yield!].

Congratulations: You got yourself some solid pure freebase Bufotenine!

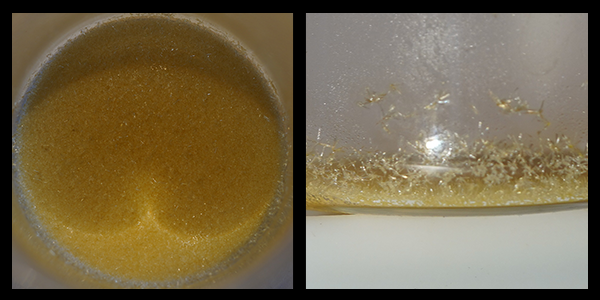

Picture of crystaline freebase Bufotenine, directly derived from the second pull of this method.

Picture of amorph freebase Bufotenine, directly derived from the first pull of this manual.

Alternative WorkupPicture of amorph freebase Bufotenine, directly derived from the first pull of this manual.

Instead of evaporating the residual 1:3 EA:Naphtha you could also add FASA and drop Bufotenine Fumarate as perfectly white crystals (next picture, left). These cant be vaporized, but you may use them for oral consumption. Regarding nasal administration it was reported that Fumarates are far less active, maybe due to the high polarity the bio availability is strongly reduced.

Also you may recrystalize the amorph Bufotenine. For this you should use Xylene and not Ethyl Acetate as mentioned in Literature. Using the latter one will turn the Bufotenin brown (next picture, right). So for recrystalization stick to the pictoral in Recrystalization part.

Picture of Bufotenine Fumarate generated from the remaining 1:3 EA:Naphtha solvent mix (left) and recrystalized Bufotenine (right) derived from the tan amorph Bufotenine. You can clearly see a darkening and these crystals turn dark, the non-recrystallized does not. Using Xylene for re-x causes no coloration.

Analytic data to verify purity of the crude Bufotenine

Picture of the GC-Chromatogram of amorph Bufotenine derived from this manual.N ow when taking a look at the GC-Chromatogram there is practically just 1 peak again. Besides that there is only 1 other peak. Possibly it's the one that causes the tan coloration and its transfered into the final product as it will still have a very low solubility even in 1:3 EA:Naphtha, so it can't be avoided by that manual. Still the GC integral is exceptionally high at 97,85 %, so there's nothing to worry.

Looking at these data it seems that even crude Bufotenine derived from this manual without any additional workup / recrystalization is already practically pure enough for instant usage with 96 % + purity.

Looking at these data it seems that even crude Bufotenine derived from this manual without any additional workup / recrystalization is already practically pure enough for instant usage with 96 % + purity.

Bufotenin recrystalization

The best solvent to form crystaline Bufotenin is Xylene. Actually it would be way too unpolar to ever dissolve Bufotenine. But the reason is as follows:As you can heat Xylene above the melting point of Bufotenin, the latter suddenly becomes soluble while liquifying, while the more polar 2 % dark impurities will remain undissolved. This way you can create 100 % purity Bufotenin from 98 % purity Bufotenin retrieved by the former mixture. See the following pictoral:

1 = Break up crude Bufotenine chunks (if even solid)

2 = Heat in Xylene > 140 °C until only brown powder is leftover (see solubility table how much to use)3 = transfer Xylene, which contains psychoactive substance, into new Jar and let it sit until psychoactive substance is clear

4 = dry crystaline Bufotenine - much faster if you wash it with low-boiling Naphtha

Bufotenine solubility table

Boiling = 7,6 g/L = 760 mg in 100 mL

20 °C = 3,6 g/1 L = 360 mg in 100 mL

- 20 °C = 3,5 g/1 L = 350 mg in 100 mL

20 °C = 3,6 g/1 L = 360 mg in 100 mL

- 20 °C = 3,5 g/1 L = 350 mg in 100 mL

Selectively dissolves Bufotenine only, not the more polar Alkaloids. Defat first with Naphtha.

Xylene

Boiling = 48 g/L = 4,8 g in 100 mL

- 20 °C = 15,3 g/L = 1,53 g in 100 mL

- 20 °C = 15,3 g/L = 1,53 g in 100 mL

Xylene is the only non-mixture solvent to form crystals. The only downside:

Solubility at - 20 °C is still high, so you will loose some or you have to evaporate after decanting. Also evaporation takes long. If using heat, then definetly watch your mixture all the time, as Bufotenin may vaporize away if all the Xylene is gone and you dont stop.Ethyl Acetate

Boiling = 280 g/1 L = 28 g in 100 mL

20 °C = 72 g/1 L = 7,2 g in 100 mL

- 20 °C = 50 g/1 L = 5 g in 100 mL

20 °C = 72 g/1 L = 7,2 g in 100 mL

- 20 °C = 50 g/1 L = 5 g in 100 mL

For recrystalization (optional, not recommended).

Although mentioned in Literature for recrystallization, this is a bad solvent. It will also catch up the more polar impurities and not improve purity and also the overall solubility is very high. This means even if using total minimum amounts of Ethyl Acetate, you will still loose a lot of Bufotenin even after cooling to -20 °C. Afterwards addition of Naphtha does not seem to improve stuff. Better use Xylene.

D-Limonene

D-Limonene

Boiling = 42 g/L

- 20 °C = 9 g/L

- 20 °C = 9 g/L

Even though it may seem as a good extraction / re-x solvent, Bufotenine turns brown from 170 °C onwards. So everything that is not dissolved fast enough will stick to the glass as a brown solid. This remainder seems not to dissolve in acetic acid anymore, indicating that the brown coloration is derived from a decomposition reaction. Maybe it gets destroyed at the boiling temp of D-Limonene, so better not use it.

1:4 Acetone:Naphtha

This solvent system is used in all old manuals. They dissolve everything in Acetone and drop contaminations by sequential addition of Naphtha. DONT use it for 2 reasons: A) The Alkaloid mix should never be fully dissolved in a polar solvent and halfly precipitated afterwards with a less polar solvent. It will not create the same purity as when extracting from a dry mass with a medium polar solvent mix (like 1:3 EA:Naphtha). B) The solvent mix 1:4 Acetone:Naphtha will not cause freeze-precipitation and you have to evaporate it. This way you will never get a crystaline product, this is the reason why all previous manuals produced an oil. Also it catches up more contaminations and cant be used for liquid-liquid-extractoins in case something goes wrong, while 1:3 EA:Naphtha can be. The manual is just finally successful based on the 1:3 EA:Naphtha mixture, so you should definetly take your time searching for Ethyl Acetate.

Freebase Bufotenine Solubility

Acetone @ 20 C: soluble (5 g/100 mL)

Chloroform @ 20 °C: soluble

Dichloromethane @ 20 °C: soluble

Dimethyl sulfoxide (DMSO) @ 20 °C: soluble (6 g/100 mL)

D-Limonene (Orange Oil) @ 20 °C: insoluble

D-Limonene (Orange Oil) @ 176 °C: soluble (more than 1.7 g/100 mL)

Ethanol @ 20 °C: soluble

Ether @ 20 °C: soluble

Ethyl acetate @ 20 °C: soluble

Heptane @ 20 °C: insoluble

Heptane with 40% MEK @ 20 °C: soluble (0.53 g/100 mL)

Heptane with 50% MEK @ 20 °C: soluble (1.22 g/100 mL)

IPA @ 20 °C: soluble

MEK @ 20 °C: soluble

Methanol @ 20 °C: soluble

Naphtha @ 20 °C: insoluble

Water @ 20 C: nearly insoluble in pure water (no acid or alkali added)

Xylene @ 20 C: nearly insoluble (less than 0.03 g/100 mL)

Xylene @ 144 C: soluble (1.5 g/100 mL)

Acetone @ 20 C: soluble (5 g/100 mL)

Chloroform @ 20 °C: soluble

Dichloromethane @ 20 °C: soluble

Dimethyl sulfoxide (DMSO) @ 20 °C: soluble (6 g/100 mL)

D-Limonene (Orange Oil) @ 20 °C: insoluble

D-Limonene (Orange Oil) @ 176 °C: soluble (more than 1.7 g/100 mL)

Ethanol @ 20 °C: soluble

Ether @ 20 °C: soluble

Ethyl acetate @ 20 °C: soluble

Heptane @ 20 °C: insoluble

Heptane with 40% MEK @ 20 °C: soluble (0.53 g/100 mL)

Heptane with 50% MEK @ 20 °C: soluble (1.22 g/100 mL)

IPA @ 20 °C: soluble

MEK @ 20 °C: soluble

Methanol @ 20 °C: soluble

Naphtha @ 20 °C: insoluble

Water @ 20 C: nearly insoluble in pure water (no acid or alkali added)

Xylene @ 20 C: nearly insoluble (less than 0.03 g/100 mL)

Xylene @ 144 C: soluble (1.5 g/100 mL)

General problems when facing Bufotenine

It seems the OH-group is causing the Bufotenine to incorporate some unconvenient traits. It will always crash out as an oil when evaporating its solvent. Only 1:3 EA:Naphtha seems to dissolve it and then drop it with an amorph or even crystaline morphology upon cooling. Sadly the solubility is not further reduced from fridge temp to freezer temp. Using Acetone or any other solvent and evaporating it will just leave a thin dark layer, very unconvenient to handle.

Also when heating it up it turns black dusty and starts giving fumes from 150 °C onwards. It dissolves much worse in Acetone afterwards, indicating a degradation upon heating.

When recrystalling Bufotenine in pure Ethyl Acetate like mentioned in literature, one needs to use an extremely high concentration, otherwise it will not precipitate. On the other hand the solvent system of 1:3 EA:Naphtha shows a very low solubility overall and not a huge decrease when being cooled. It works perfectly to selectively dissolve Bufotenine, but maybe in near future a different mixture will be elaborated, that may dissolve Bufotenine the same way Naphtha is handled when using it with DMT.

Also when heating it up it turns black dusty and starts giving fumes from 150 °C onwards. It dissolves much worse in Acetone afterwards, indicating a degradation upon heating.

When recrystalling Bufotenine in pure Ethyl Acetate like mentioned in literature, one needs to use an extremely high concentration, otherwise it will not precipitate. On the other hand the solvent system of 1:3 EA:Naphtha shows a very low solubility overall and not a huge decrease when being cooled. It works perfectly to selectively dissolve Bufotenine, but maybe in near future a different mixture will be elaborated, that may dissolve Bufotenine the same way Naphtha is handled when using it with DMT.

General tipp: how to turn a sticky goo into dry solids

Often when a goo is collected at the end of any extraction (not only this but general) it may be due to solvent traces still trapped inside of your freebase. Even though organic solvents often evaporate really fast even at ambient temperature, they may be "stuck" inside of that oil and held back to even not fully evaporate after days.To remove it cover your oily Bufotenine/whatever with a low boiling solvent, that does not dissolve the substance at any temperatures. This may be for example very-low boiling Naphtha (40 - 60 °C) in case of Bufotenine. Now boil it under vigorously stirring. This distributes the former trapped solvent between the freebase and the new solvent and therefore reduces the amount in your freebase oil by far. Then just decant it and let the low boiling solvent evaporate. This may turn sticky goos into a solid. If it is a goo due to impurities, then this may not help. But proceeding all the steps like in this manual should most certainly yield Bufotenine with high purity that will easily solidify by itself.

General tipp: Extracting the lesser polar Bufotenine from the more polar Alkaloids

In both the 2 big sticky threads about Bufotenine it is mentioned to fully dissolve a crude extract in Acetone (with all the Bufotenine and all the more polar Impurities). Afterwards you shall add a certain amount of Naphtha to precipitate that impurities again, while keeping Bufotenine in solution.

This is actually not recommended, as while in theory the more polar Impurities dont dissolve in a solvent mix of a reduced polarity (like 1:4 Acetone:Naphtha) they will not fully crash out when adding the Naphtha afterwards and therefore the Bufotenine will never become pure. It is strongly recommended to extract directly with your solvent mix of reduced polarity on a dry substance, selectively dissolving Bufotenine. Also in case you have problems and need to extract from an aqueous layer, it wont be possible with 1:4 Acetone:Naphtha, as Acetone is partially soluble in water. With 1:3 EA:Naphtha you can do it.

This is actually not recommended, as while in theory the more polar Impurities dont dissolve in a solvent mix of a reduced polarity (like 1:4 Acetone:Naphtha) they will not fully crash out when adding the Naphtha afterwards and therefore the Bufotenine will never become pure. It is strongly recommended to extract directly with your solvent mix of reduced polarity on a dry substance, selectively dissolving Bufotenine. Also in case you have problems and need to extract from an aqueous layer, it wont be possible with 1:4 Acetone:Naphtha, as Acetone is partially soluble in water. With 1:3 EA:Naphtha you can do it.

Last edited: