- Language

- 🇺🇸

- Joined

- Feb 26, 2023

- Messages

- 45

- Reaction score

- 30

- Points

- 18

This article provides you with a patented synthesis process from benzaldehyde to BMK glycidyl ester to P2P.

This process comes from a patent published in 2009. The original text used 4-methoxybenzaldehyde to synthesize 4-methoxyphenylacetone. I replaced it with benzaldehyde to synthesize phenylacetone.

This process does not separate BMK glycidyl ester.

The literature indicates that the yield of this process from benzaldehyde to distilled phenylacetone is 82.9%.

Mr. G. Patton previously provided another solution for this process on the forum, and I have made some comments under this post.(https://bbgate.com/threads/bmk-glyc...p2p-synthesis-from-bmk-glycidate-ethers.4307/)

Since my English level is not very good, this article was translated by Google after writing, please forgive me if there is any grammatical incomprehension.

Practice steps:

-A 2000ml reaction device, kept clean and dry, must be completely anhydrous.

-Add 280g of 30% sodium methoxide-methanol solution. (If you are using 28% sodium methoxide-methanol solution, you need 300g)

-Start the condensing pipe, install the drying pipe above the condensing pipe to isolate the external water.

-Add the mixed solution of 104g benzaldehyde and 232g methyl 2-chloropropionate using constant pressure dropping funnel under stirring.

-After the addition, the inside of the flask will spontaneously heat up to around 60°C. At this time, adjust the heating temperature to maintain the inside of the flask at 60°C.

-Stir and reflux at 60°C for 2 hours.

-Add 1160ml of 3mol/L hydrochloric acid under stirring.

-After adding, heat to 90°C under high-speed stirring, stir and reflux at this temperature for 4 hours, please ensure continuous stirring.

-Cool to within 20°C.

-Use a separatory funnel to separate the oil layer.

-Use 3×100ml dichloromethane to extract the aqueous layer, and combine all extracts and oil layers.

-Use 200 g of 5% aqueous sodium bisulfite (NaHSO ) to wash the organic layer.

-Use 2×200ml 1% sodium hydroxide solution to wash the organic layer to ensure that the pH value of the aqueous layer is greater than or equal to 7.

-Filter the oil layer through a sand core funnel covered with 1.5cm thick anhydrous magnesium sulfate to dry thoroughly, rinse the sand core funnel with a small amount of dichloromethane and combine.

-Use a rotary evaporator to remove low-boiling point solvents at 70 °C under reduced pressure.

-Build an atmospheric distillation device, collect the main fraction from 210°C to 240°C, and obtain yellow 1-phenyl-2-propanone.

-If produced in large quantities, colorless phenylacetone can be obtained by one more vacuum distillation.

Precautions:

-Once there is moisture in the reaction device before adding hydrochloric acid, the yield will be severely reduced or even the reaction will not occur.

-After adding hydrochloric acid, it is necessary to use strong stirring to fully mix the reaction solution. Because it is an oil-water cross-phase reaction, the reaction depends largely on the contact area. After calculation, the difference in contact area between stirring and non-stirring can reach hundreds or even thousands of times!

-Please pay attention to whether the temperature is lower than 20°C before extraction. If the temperature is too high, dichloromethane will expand the separatory funnel and open the separatory funnel.

-Washing with sodium bisulfite can add to remove a small amount of unreacted benzaldehyde to improve the purity. Benzaldehyde is not easy to remove during distillation. Please do not delete this step at will.

-The process of sodium bisulfite washing and the first sodium hydroxide washing process will be more difficult to separate, and it will take a long time to stand, please wait patiently.

-Please make sure the liquid is dry before distilling, otherwise the distillation is prone to bumping.

-30% sodium methoxide/methanol solution try to buy the finished product directly, do not use solid sodium methoxide and anhydrous methanol to manufacture.

Experience:

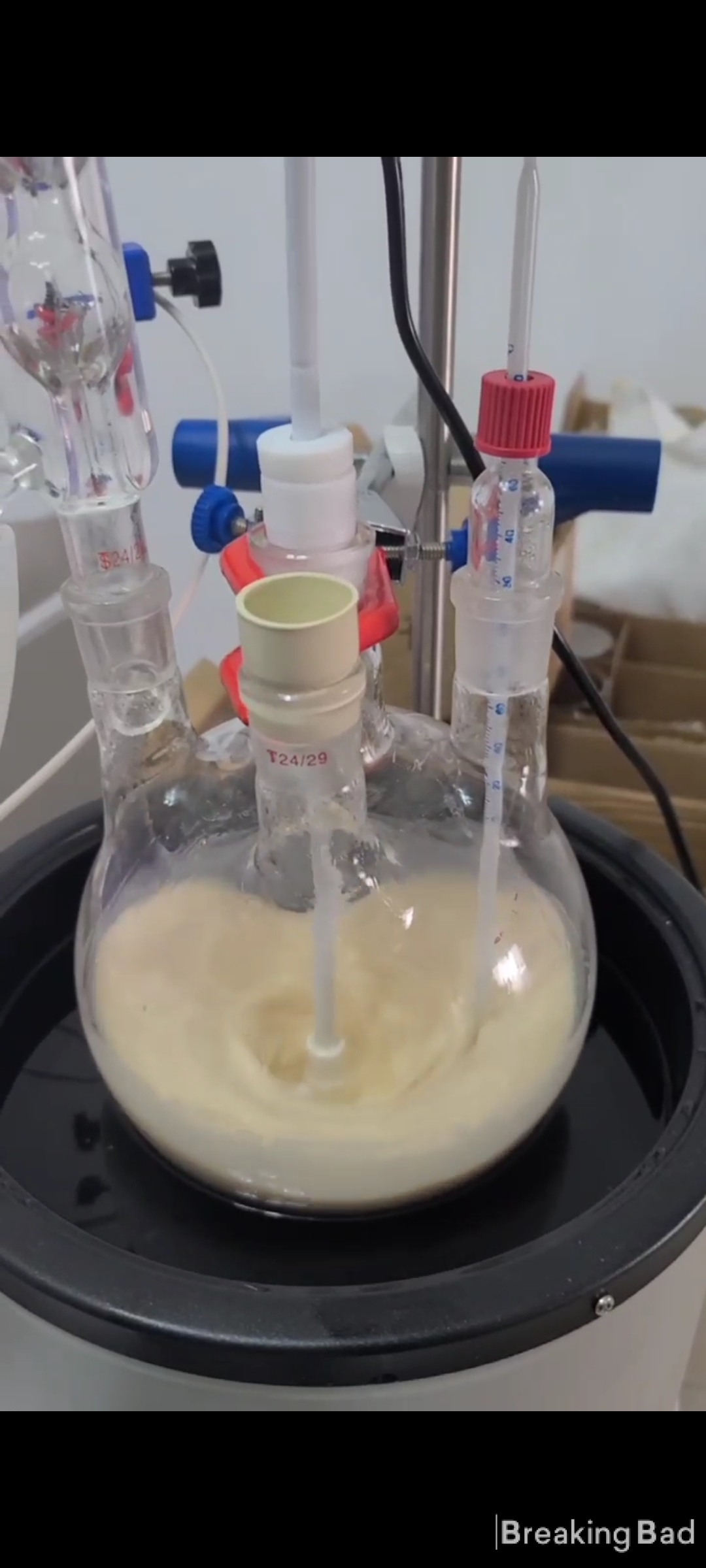

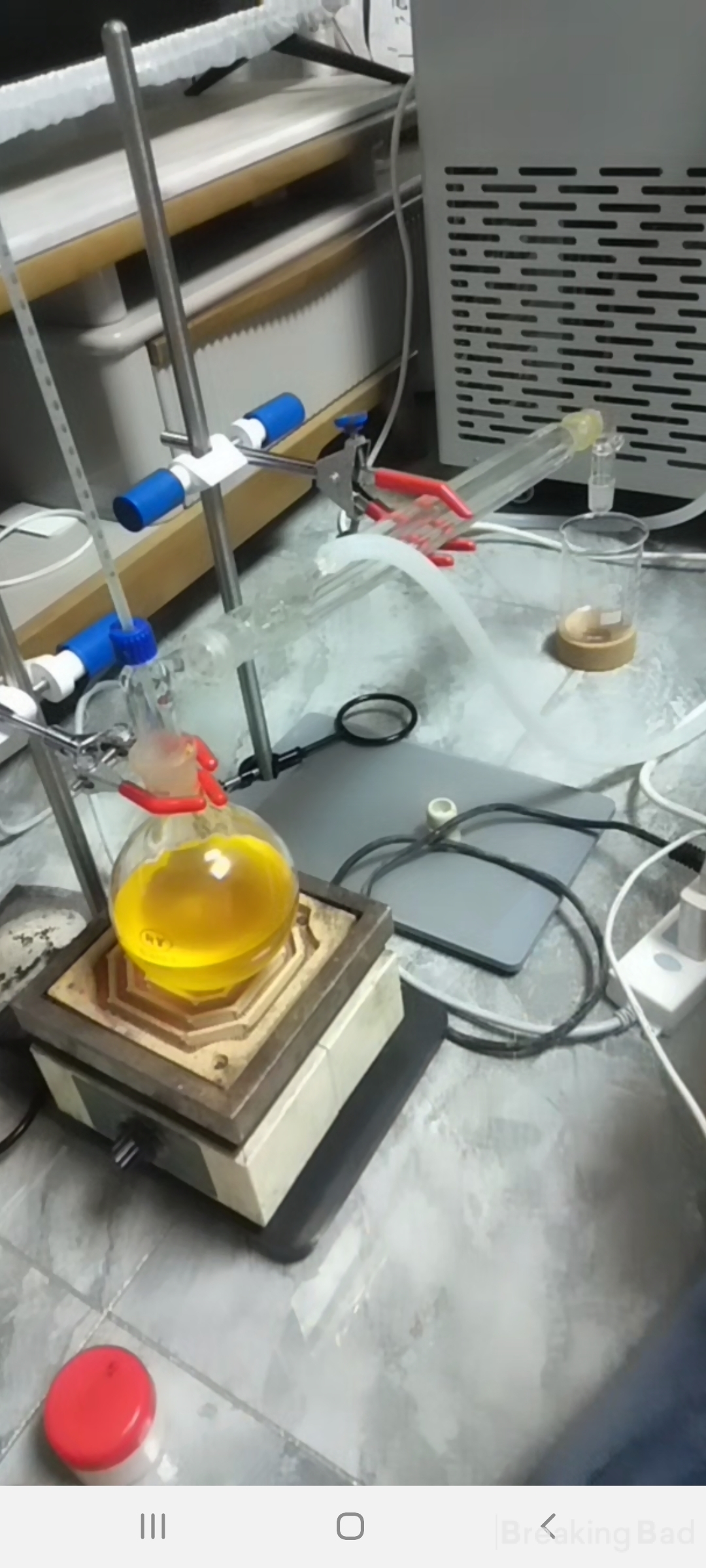

The first step reaction of benzaldehyde with methyl 2-chloropropionate and sodium methoxide under reflux at 60°C is shown in the figure below. The process of adding benzaldehyde and methyl 2-chloropropionate to the sodium methoxide solution will boil, please control the adding speed reasonably.

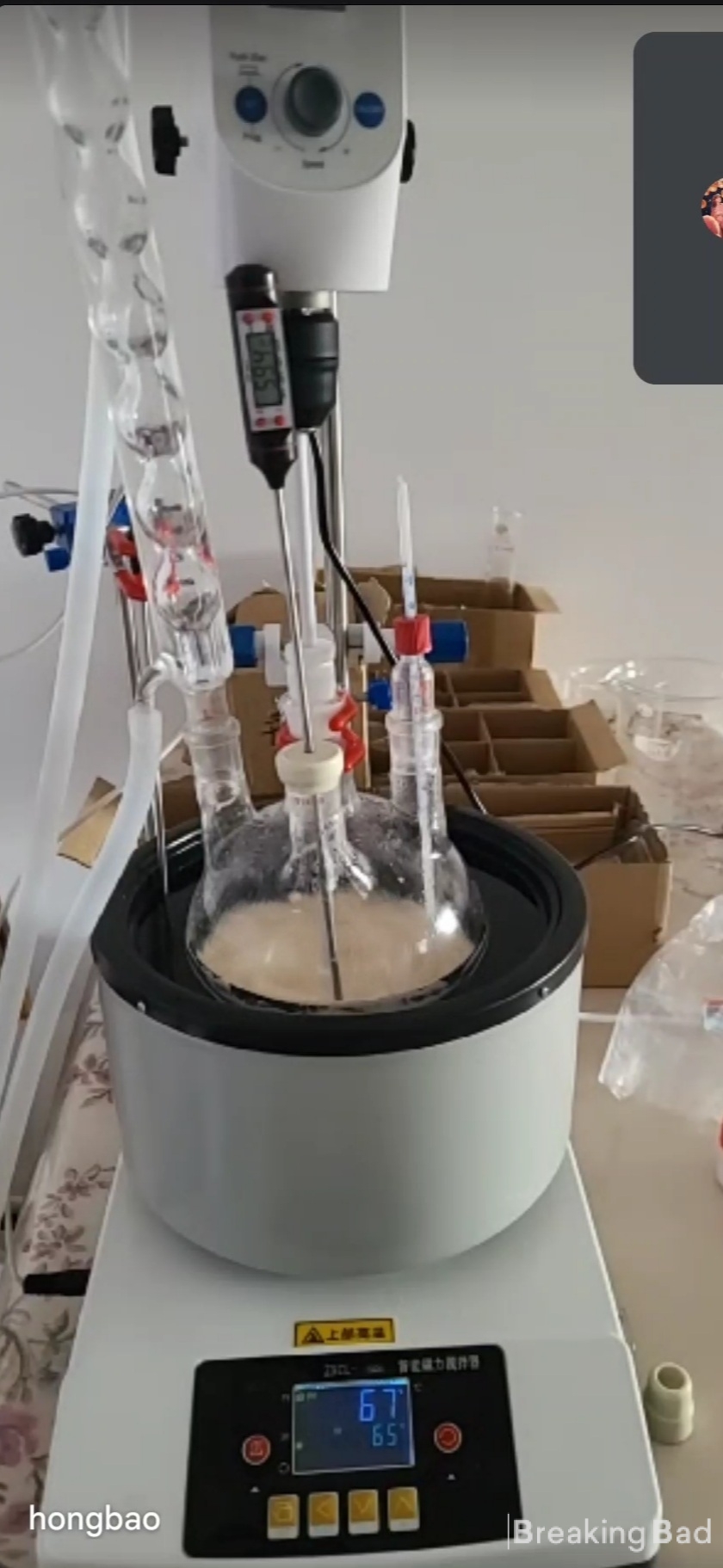

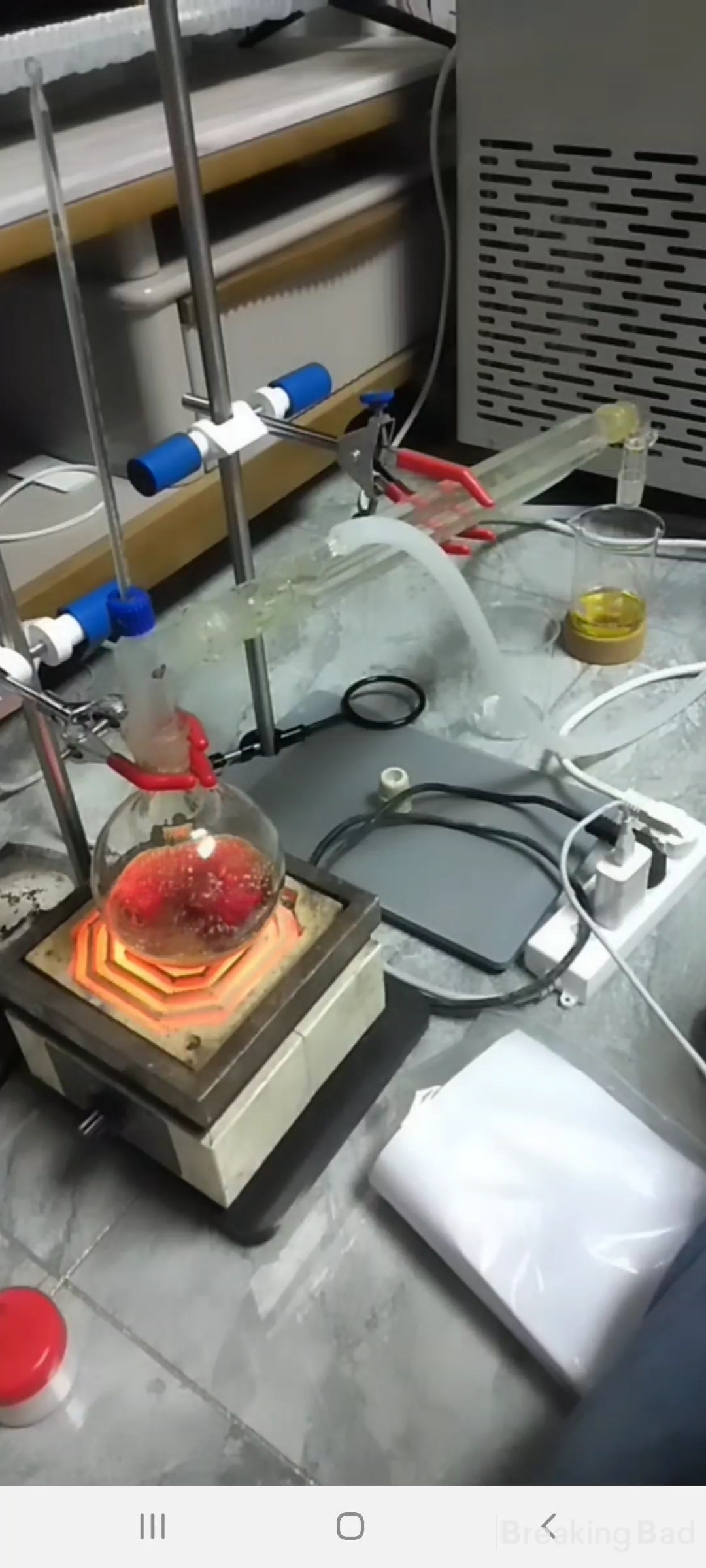

The process of reflux at 90°C after adding hydrochloric acid is shown in the figure below.

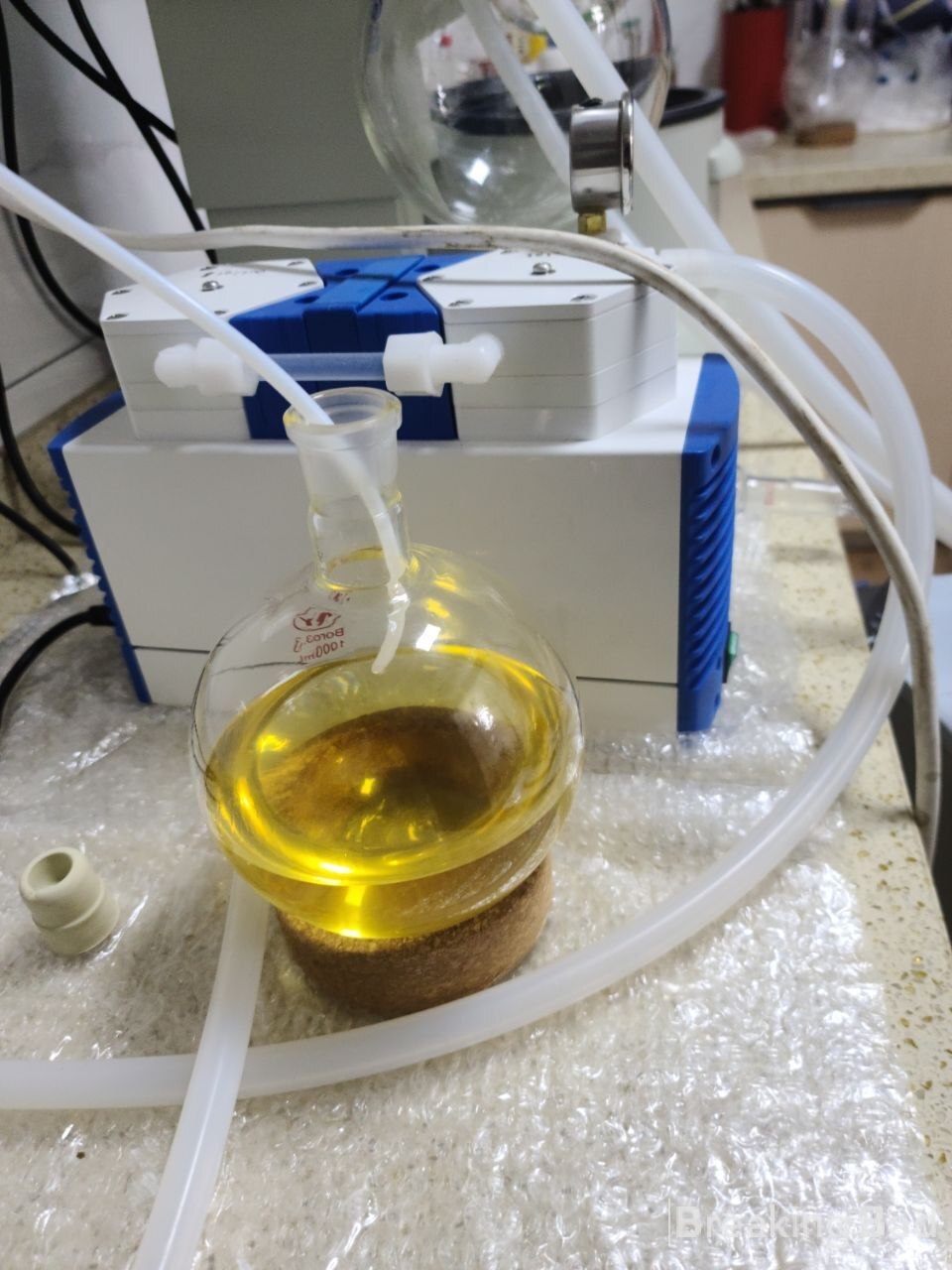

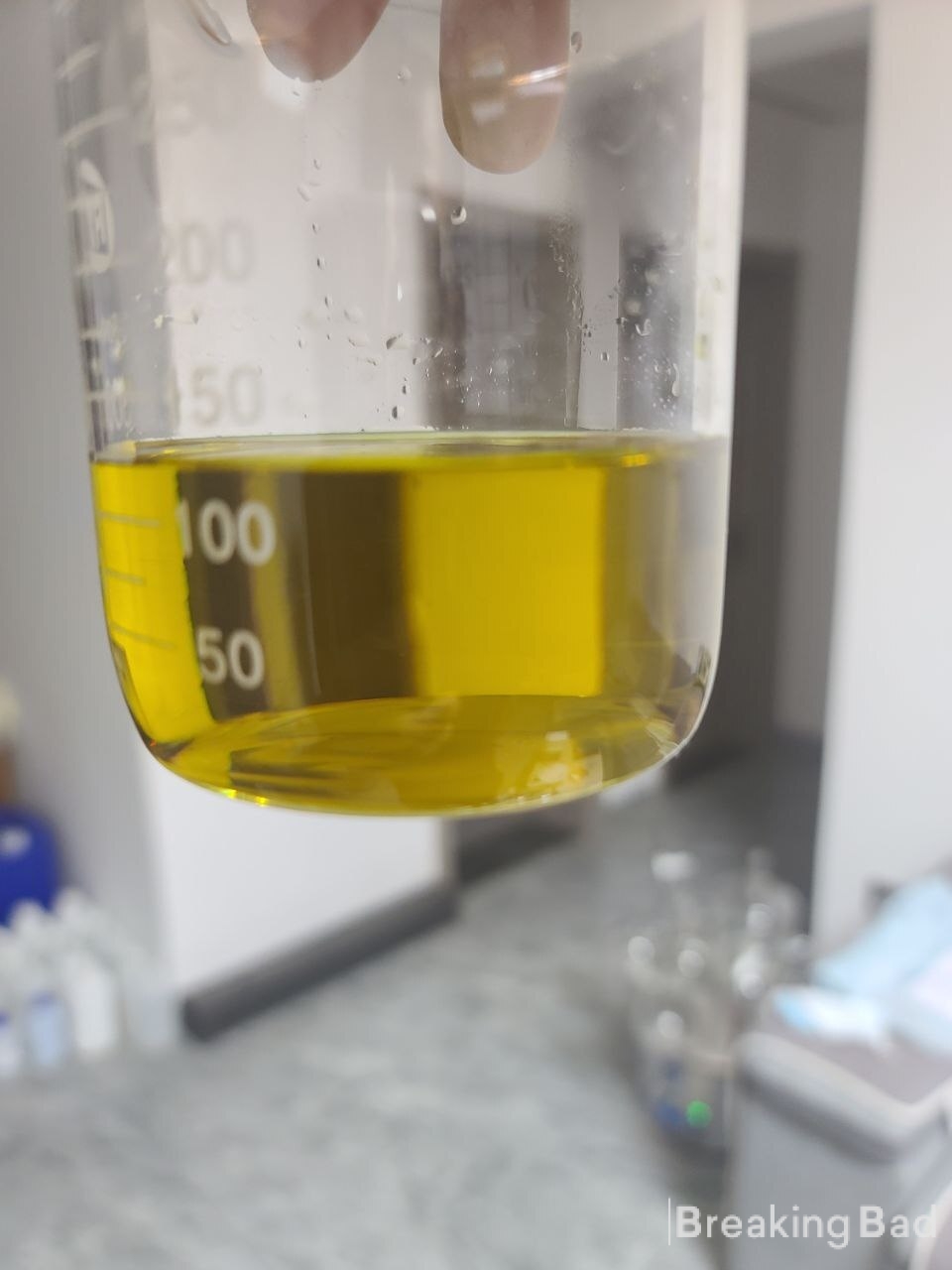

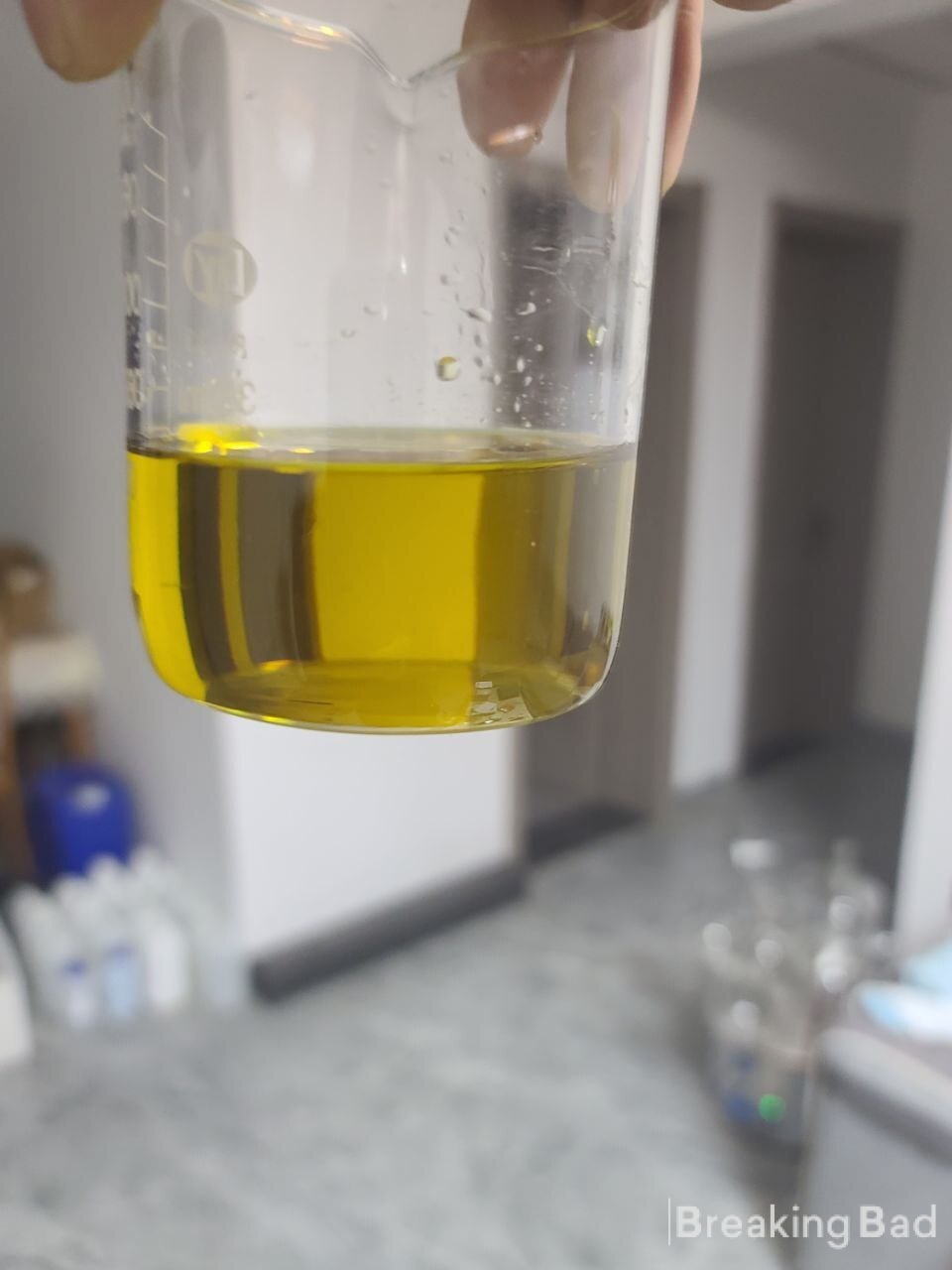

The oil layer after extraction and washing is shown in the figure below.

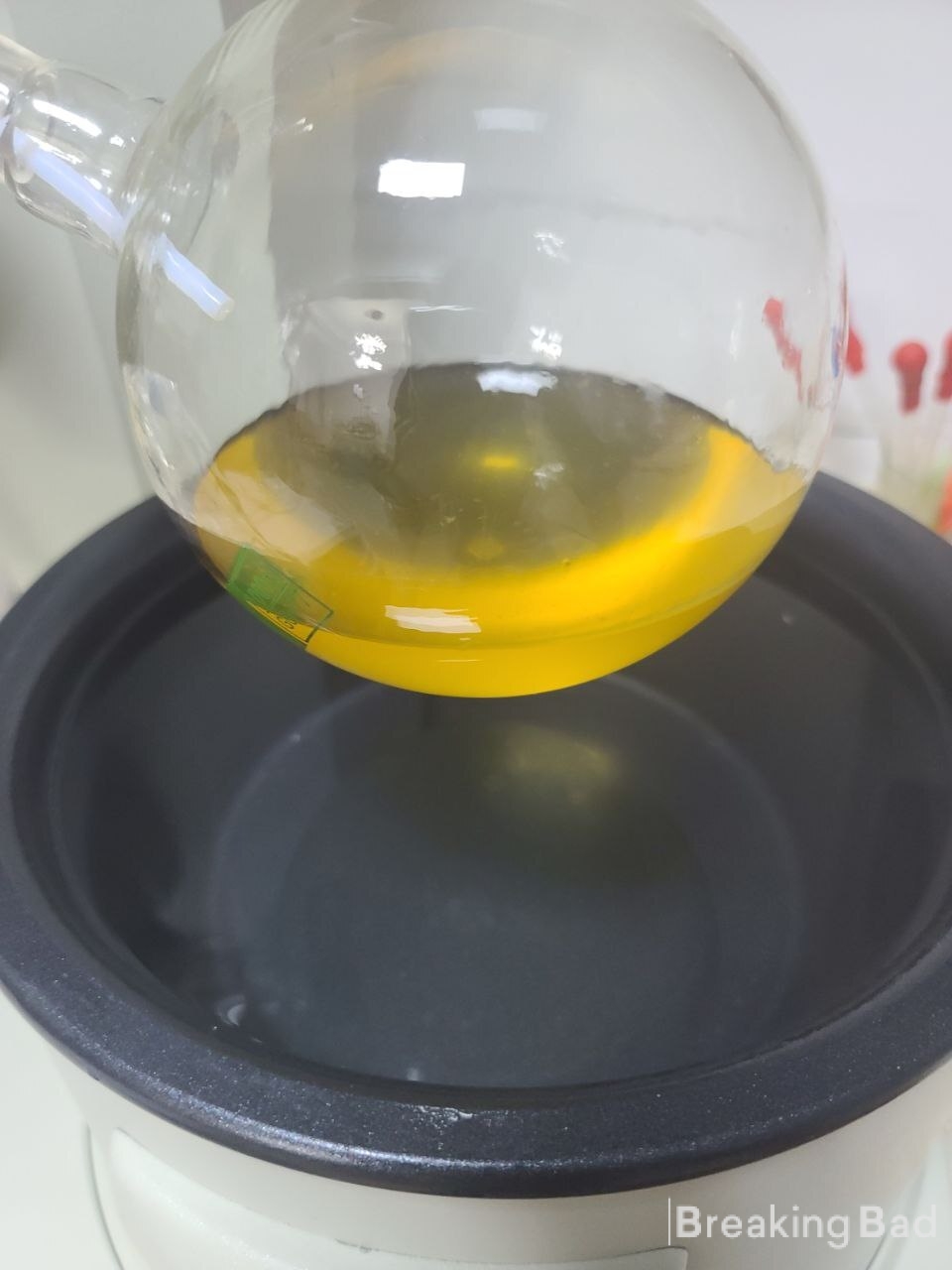

Use a rotary evaporator to evaporate the low boiling point solvent at 70°C, as shown in the figure below.

The distillation apparatus is shown in the figure below.

The total volume before distillation is about 250ml to 300ml. It is the total amount obtained from two operations. During the distillation process, about 70ml of colorless distillate flows out below 110°C. It has organic solvents and some pungent odors. It should be a low boiling point solvent.

From 110°C to 160°C, about 20ml of colorless distillate flowed out, with a pungent smell. Possibly methyl 2-chloropropionate and some product esters at this boiling point.

From 160°C to 210°C, less than 5ml of a colorless distillate flows out, which has the smell of benzaldehyde, which may be benzaldehyde.

When it is close to 210°C, the distillate starts to turn yellow, and the temperature fluctuates from 210°C to 240°C. 120ml of distillate flows out, which is olive yellow and has a consistency similar to that of olive oil at normal temperature. Main fraction with P2P.

When reddish-brown steam starts to evaporate in the flask, the distillation is over, and about 25ml of residue remains in the flask.

The P2P fraction is shown in the figure below.

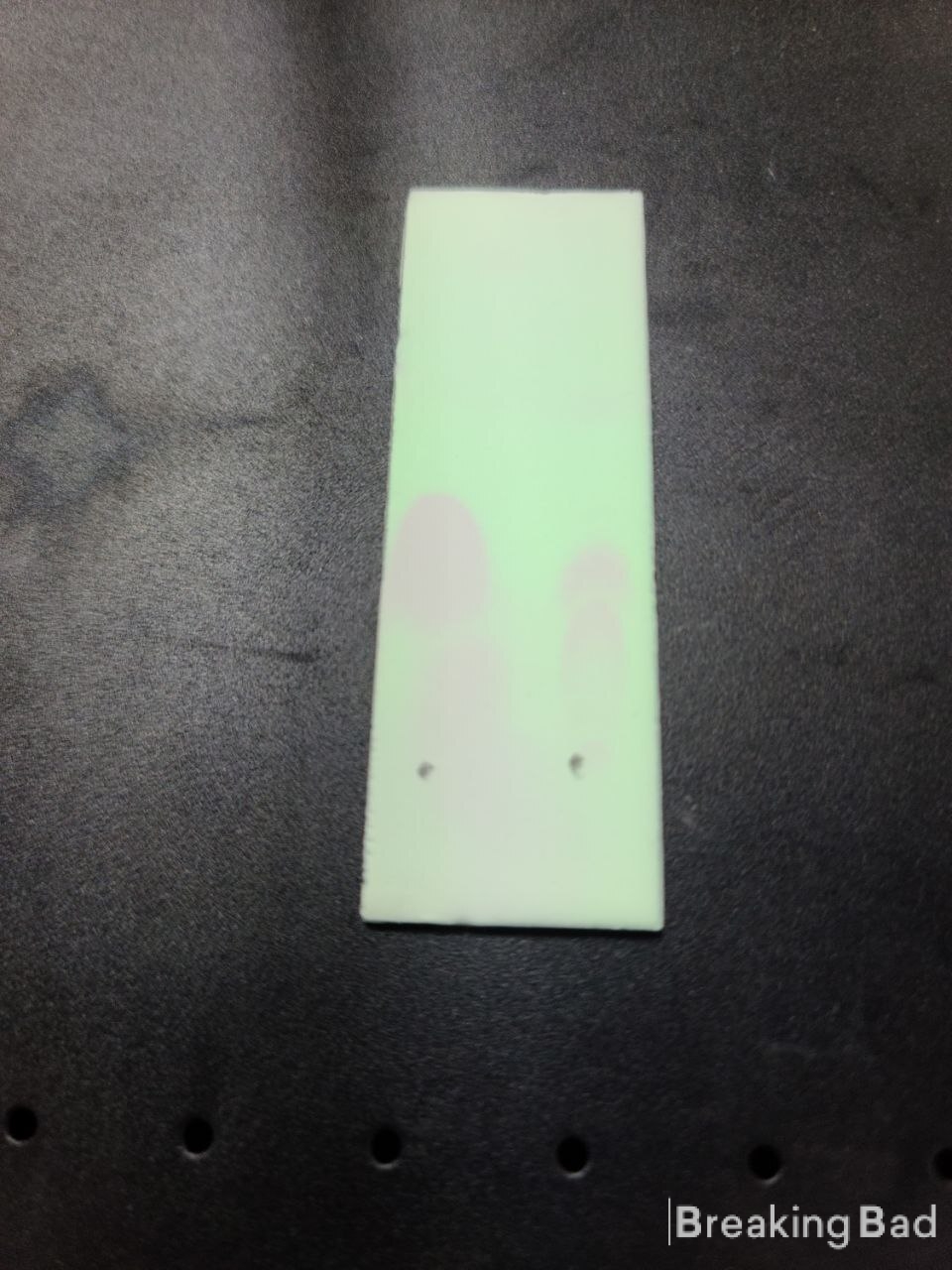

The TLC comparison of distilled P2P and benzaldehyde is shown in the figure below.

Maybe due to some mistakes in the operation of the production personnel, the yield is much lower than the yield in the literature. I will continue to update the follow-up yield. In addition, we can see through TLC that the presence of benzaldehyde is no longer visible in the distilled P2P, but it is still impure, with two very obvious components. The impurities are unknown, and it is obvious that distillation cannot remove them.

At present, I plan to separate the components and send them to the testing agency for nuclear magnetic resonance testing to determine the product components and impurity structure, but due to insufficient funds, I am here to initiate crowdfunding to netizens on the BB forum. Below is my cryptocurrency collection It is estimated that perfecting this process will require about 10 to 12 NMR tests and some consumables, and the total cost will be about 1500 to 1800 US dollars. Once the funds are sufficient, I will use liquid chromatography to separate the product components and perform NMR detection, and then post the detection results on the BB forum. Then I will make targeted improvements to the process based on the test results, with the aim of obtaining high-purity P2P using a simple and repeatable process, and then I will continue to update these progress on the BB forum, thanks.

This process comes from a patent published in 2009. The original text used 4-methoxybenzaldehyde to synthesize 4-methoxyphenylacetone. I replaced it with benzaldehyde to synthesize phenylacetone.

This process does not separate BMK glycidyl ester.

The literature indicates that the yield of this process from benzaldehyde to distilled phenylacetone is 82.9%.

Mr. G. Patton previously provided another solution for this process on the forum, and I have made some comments under this post.(https://bbgate.com/threads/bmk-glyc...p2p-synthesis-from-bmk-glycidate-ethers.4307/)

Since my English level is not very good, this article was translated by Google after writing, please forgive me if there is any grammatical incomprehension.

Practice steps:

-A 2000ml reaction device, kept clean and dry, must be completely anhydrous.

-Add 280g of 30% sodium methoxide-methanol solution. (If you are using 28% sodium methoxide-methanol solution, you need 300g)

-Start the condensing pipe, install the drying pipe above the condensing pipe to isolate the external water.

-Add the mixed solution of 104g benzaldehyde and 232g methyl 2-chloropropionate using constant pressure dropping funnel under stirring.

-After the addition, the inside of the flask will spontaneously heat up to around 60°C. At this time, adjust the heating temperature to maintain the inside of the flask at 60°C.

-Stir and reflux at 60°C for 2 hours.

-Add 1160ml of 3mol/L hydrochloric acid under stirring.

-After adding, heat to 90°C under high-speed stirring, stir and reflux at this temperature for 4 hours, please ensure continuous stirring.

-Cool to within 20°C.

-Use a separatory funnel to separate the oil layer.

-Use 3×100ml dichloromethane to extract the aqueous layer, and combine all extracts and oil layers.

-Use 200 g of 5% aqueous sodium bisulfite (NaHSO ) to wash the organic layer.

-Use 2×200ml 1% sodium hydroxide solution to wash the organic layer to ensure that the pH value of the aqueous layer is greater than or equal to 7.

-Filter the oil layer through a sand core funnel covered with 1.5cm thick anhydrous magnesium sulfate to dry thoroughly, rinse the sand core funnel with a small amount of dichloromethane and combine.

-Use a rotary evaporator to remove low-boiling point solvents at 70 °C under reduced pressure.

-Build an atmospheric distillation device, collect the main fraction from 210°C to 240°C, and obtain yellow 1-phenyl-2-propanone.

-If produced in large quantities, colorless phenylacetone can be obtained by one more vacuum distillation.

Precautions:

-Once there is moisture in the reaction device before adding hydrochloric acid, the yield will be severely reduced or even the reaction will not occur.

-After adding hydrochloric acid, it is necessary to use strong stirring to fully mix the reaction solution. Because it is an oil-water cross-phase reaction, the reaction depends largely on the contact area. After calculation, the difference in contact area between stirring and non-stirring can reach hundreds or even thousands of times!

-Please pay attention to whether the temperature is lower than 20°C before extraction. If the temperature is too high, dichloromethane will expand the separatory funnel and open the separatory funnel.

-Washing with sodium bisulfite can add to remove a small amount of unreacted benzaldehyde to improve the purity. Benzaldehyde is not easy to remove during distillation. Please do not delete this step at will.

-The process of sodium bisulfite washing and the first sodium hydroxide washing process will be more difficult to separate, and it will take a long time to stand, please wait patiently.

-Please make sure the liquid is dry before distilling, otherwise the distillation is prone to bumping.

-30% sodium methoxide/methanol solution try to buy the finished product directly, do not use solid sodium methoxide and anhydrous methanol to manufacture.

Experience:

The first step reaction of benzaldehyde with methyl 2-chloropropionate and sodium methoxide under reflux at 60°C is shown in the figure below. The process of adding benzaldehyde and methyl 2-chloropropionate to the sodium methoxide solution will boil, please control the adding speed reasonably.

The process of reflux at 90°C after adding hydrochloric acid is shown in the figure below.

The oil layer after extraction and washing is shown in the figure below.

Use a rotary evaporator to evaporate the low boiling point solvent at 70°C, as shown in the figure below.

The distillation apparatus is shown in the figure below.

The total volume before distillation is about 250ml to 300ml. It is the total amount obtained from two operations. During the distillation process, about 70ml of colorless distillate flows out below 110°C. It has organic solvents and some pungent odors. It should be a low boiling point solvent.

From 110°C to 160°C, about 20ml of colorless distillate flowed out, with a pungent smell. Possibly methyl 2-chloropropionate and some product esters at this boiling point.

From 160°C to 210°C, less than 5ml of a colorless distillate flows out, which has the smell of benzaldehyde, which may be benzaldehyde.

When it is close to 210°C, the distillate starts to turn yellow, and the temperature fluctuates from 210°C to 240°C. 120ml of distillate flows out, which is olive yellow and has a consistency similar to that of olive oil at normal temperature. Main fraction with P2P.

When reddish-brown steam starts to evaporate in the flask, the distillation is over, and about 25ml of residue remains in the flask.

The P2P fraction is shown in the figure below.

The TLC comparison of distilled P2P and benzaldehyde is shown in the figure below.

Maybe due to some mistakes in the operation of the production personnel, the yield is much lower than the yield in the literature. I will continue to update the follow-up yield. In addition, we can see through TLC that the presence of benzaldehyde is no longer visible in the distilled P2P, but it is still impure, with two very obvious components. The impurities are unknown, and it is obvious that distillation cannot remove them.

At present, I plan to separate the components and send them to the testing agency for nuclear magnetic resonance testing to determine the product components and impurity structure, but due to insufficient funds, I am here to initiate crowdfunding to netizens on the BB forum. Below is my cryptocurrency collection It is estimated that perfecting this process will require about 10 to 12 NMR tests and some consumables, and the total cost will be about 1500 to 1800 US dollars. Once the funds are sufficient, I will use liquid chromatography to separate the product components and perform NMR detection, and then post the detection results on the BB forum. Then I will make targeted improvements to the process based on the test results, with the aim of obtaining high-purity P2P using a simple and repeatable process, and then I will continue to update these progress on the BB forum, thanks.

Last edited by a moderator: