G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 3,197

- Solutions

- 3

- Reaction score

- 3,670

- Points

- 113

- Deals

- 1

Introduction

Vacuum supply is usually an integral part of planning for laboratories in public or private buildings. It is more complex than other piped utilities because the requirements for vacuum technology are different in a synthesis laboratory than, for example, in an analytical or cell biology laboratory. These different requirements cannot be met with the same vacuum supply. To address the need for vacuum supply tailored to the applications, the specific requirements should be clarified early in the planning phase. “The right tool saves time” is an old saying of craftsmen that applies to the vacuum supplied to each laboratory. Whether because vacuum is poorly understood because the piping systems seem so similar to piped gases, or because traditional practice has dictated a single building-wide system, the unique requirements of vacuum supply are frequently overlooked in the lab planning process. Nonetheless, for many applications, tailored vacuum is invaluable. Appropriate vacuum allows the chemists to achieve desired results faster, more safely, more conveniently and also reproducible. This topic is intended to be an initial orientation for small laboratory planners, underground chemists and drug manufacturers to the important consideration in planning vacuum supply for laboratories.

What is the vacuum?

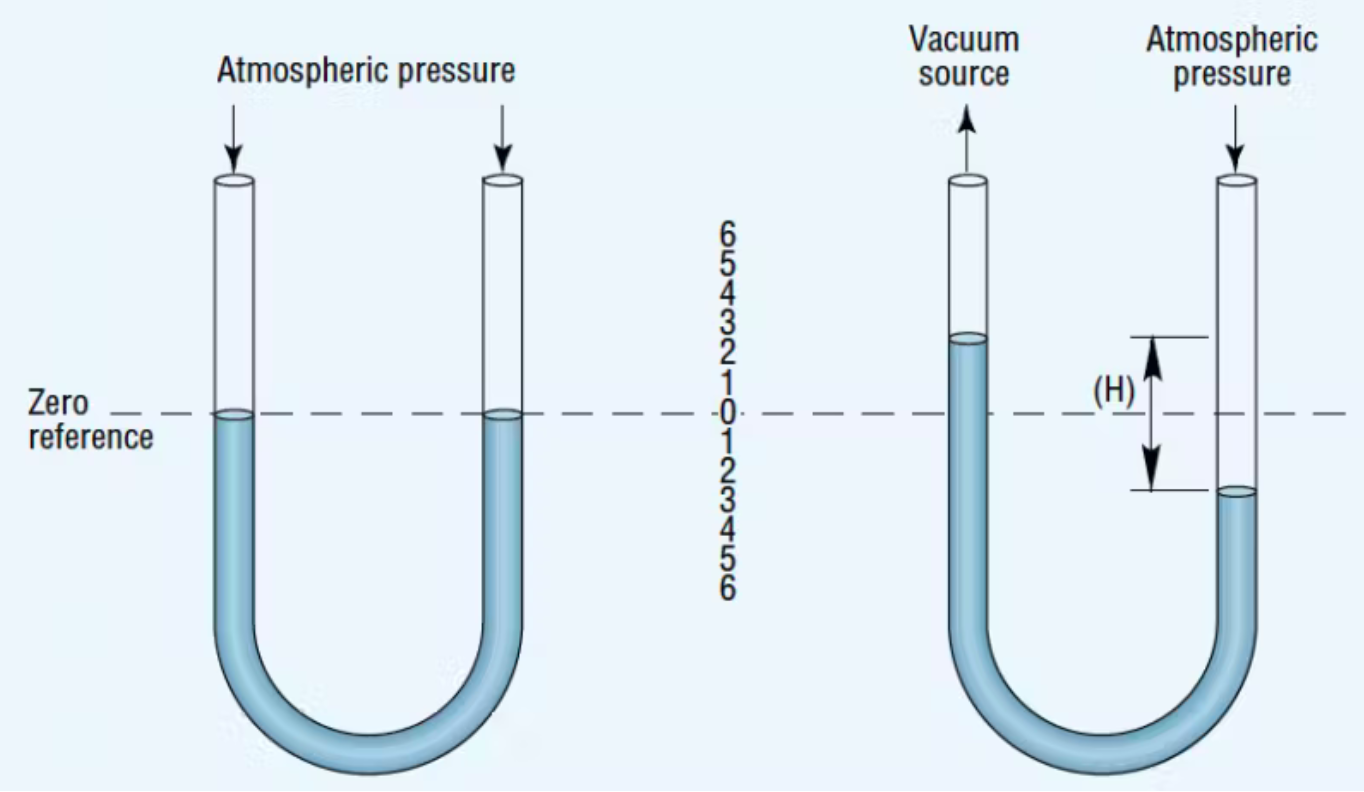

Vacuum as used in the laboratory is simply pressure below atmospheric pressure. The essential qualities of the vacuum that determine its usefulness in any particular laboratory application are the depth of vacuum – how much below atmospheric pressure and the pumping speed, that is, how quickly can air, vapors or gases be removed from the vessel being evacuated.

Application

Many chemists use vacuum every day. But how do they use it? Vacuum is used for many standard applications in the preparation and processing of synthesis products. In most cases, the vacuum is not the focus, but plays an essential supporting role. The most familiar lab vacuum applications are filtration and drying. Of course, you could filter without vacuum - like brewing coffee - by letting gravity do the work for you. The problem is that, in the laboratory, the process often proves to be too slow due to the broad spectrum of solvents and solid substances. To speed up the process, low-pressure – i.e., vacuum – is created in a filter flask (Büchner flask) for Suction (vacuum) filtration.

Filtration with the aid of a chemical-resistant vacuum pump

In a drying process, on the other hand, the goal is to change the state of a sample from liquid to gaseous. We could simply allow drying to happen, just as we air-dry laundry. As with filtration, this process would also take too much time, so a vacuum is used here as well to accelerate the process with help of Vacuum desiccators. Heat could be used to accomplish the same effect, but by decreasing the pressure level, less heat energy is necessary to evaporate solvents. Thus, use of vacuum makes possible the efficient drying of heat-sensitive sample materials.

Vacuum applications used in laboratories vary with the scientific discipline, and the different applications have distinct vacuum requirements. Filtration is a process used in nearly all laboratories. Synthetic laboratories in which produce some solid (meth, amph, mephedrone, MDMA and etc) commonly use vacuum for drying. These applications all require vacuum in the “rough vacuum” range – between 1 and 1000 mbar.

In chemistry laboratories, numerous vacuum-driven technologies are used for evaporative separation of mixtures of substances such as solvents. The best known example of this is Rotary evaporation, for which the precise control and pressure regulation impose significant requirements regarding to pump and control technology in the rough vacuum range. This equipment allows evaporating solvents quickly without intensive heating, also you can recuperate solvents after synthesis from waste.

In contrast, Schlenk line and Vacuum distillation, also common in chemistry labs, demand vacuum in the fine vacuum range. This technique is used when the boiling point of the desired compound is difficult to achieve or will cause the compound to decompose. Reduced pressures decrease the boiling point of compounds.

Pumps

DiaphragmDiaphragm pumps use a flexible diaphragm and a set of check valves to produce pumping pressure and typically produce low to medium vac. They are frequently resistant to solvent and mildly corrosive vapors, making them useful for rotary evaporators, but their inability to produce high vacuum limits their utility. Diaphragm pumps often do not require oil. This type of pump may produce to 1.5 mbar vacuum. Main disadvantage is a produced noise to 50-60 dB and necessity of periodic maintenance (replacement of oil and membranes). Diaphragm pumps have cost from ~450-$500.

Rotary Vane

Rotary-vane pumps are also a common type of vacuum pump, with two-stage pumps able to reach pressures well below 10−6 bar. Rotary vane pumps use rotating sets of circular vanes in an elliptical cavity to create pumping pressure, and can achieve medium to high vacuum. If your pump requires oil changes, it is likely a rotary vane pump. Though they can achieve higher vacuum than diaphragm pumps, they are easily damaged by solvent or corrosive vapors. Steps must be taken to prevent harmful vapors from reaching this type of pump, such as the implementation of a cold trap, as contamination can significantly reduce a pump's efficiency and lifetime. Approximate cost from 150-$200.

Rotary-vane pumps are also a common type of vacuum pump, with two-stage pumps able to reach pressures well below 10−6 bar. Rotary vane pumps use rotating sets of circular vanes in an elliptical cavity to create pumping pressure, and can achieve medium to high vacuum. If your pump requires oil changes, it is likely a rotary vane pump. Though they can achieve higher vacuum than diaphragm pumps, they are easily damaged by solvent or corrosive vapors. Steps must be taken to prevent harmful vapors from reaching this type of pump, such as the implementation of a cold trap, as contamination can significantly reduce a pump's efficiency and lifetime. Approximate cost from 150-$200.

Water jet pump

The water jet pump is a propellant jet pump in which water flows through a nozzle. A vacuum develops as a result of the high flow rate. The final vacuum to be reached depends on the water pressure and temperature (for water, 3.2 kPa or 0.46 psi or 32 mbar at 25 °C or 77 °F). If not considering the source of the working fluid, vacuum ejectors can be significantly more compact than a self-powered vacuum pump of the same capacity. Approximate cost ~25-$30. The lower the intake pressure, the more the suction capacity declines. Water jet pumps are distinguished by their very low acquisition costs and corrosion resistance. However, they are stationary. To use them, water and wastewater connections must be mounted on laboratory tables and in exhaust hoods. Because of the typical water consumption of several hundred liters per hour - a hundred thousand liters per year, even with moderate use – the water jet pumps generate high operating costs for fresh water and wastewater. Another drawback is the high noise level and the poor environmental compatibility, since all substances and solvent vapors pumped from applications go into wastewater.

The water jet pump is a propellant jet pump in which water flows through a nozzle. A vacuum develops as a result of the high flow rate. The final vacuum to be reached depends on the water pressure and temperature (for water, 3.2 kPa or 0.46 psi or 32 mbar at 25 °C or 77 °F). If not considering the source of the working fluid, vacuum ejectors can be significantly more compact than a self-powered vacuum pump of the same capacity. Approximate cost ~25-$30. The lower the intake pressure, the more the suction capacity declines. Water jet pumps are distinguished by their very low acquisition costs and corrosion resistance. However, they are stationary. To use them, water and wastewater connections must be mounted on laboratory tables and in exhaust hoods. Because of the typical water consumption of several hundred liters per hour - a hundred thousand liters per year, even with moderate use – the water jet pumps generate high operating costs for fresh water and wastewater. Another drawback is the high noise level and the poor environmental compatibility, since all substances and solvent vapors pumped from applications go into wastewater.

Vacuum pump selection

In underground chemistry laboratory, vacuum is among the basic equipment for laboratory workstations. Consequently, vacuum supply is already an integral part of the planning of new laboratories, since it is needed for many applications - whether evaporation, distillation, drying or simply aspiration or filtration. These rough vacuum applications are best served by chemistry diaphragm pumps.

Safety

Care should be used to avoid venting harmful vapors into the lab atmosphere. Pump exhaust should be either vented into a fume hood, or fitted with an appropriate scrubber or filter. When broken, evacuated glassware shatters and violently implodes, sending fragments flying at high velocity. Inspect your glassware for cracks and flaws before applying vacuum.

Last edited: