GhostChemist

Expert

- Joined

- Nov 20, 2022

- Messages

- 88

- Reaction score

- 184

- Points

- 33

Reagents and materials:

The flask for steam distillation is filled with P2P to be purified, and then it is half-filled with a pre-prepared solution of potassium carbonate. Fig 1

A steam condenser is connected, and the entire setup for steam distillation is assembled. The amount of steam from the steam generator should be greater than what would be produced during the regular boiling of the P2P in the flask (i.e., the flask containing P2P should be smaller in volume than the steam generator). Fig 2

The mass in the distillation flask is adjusted to achieve a uniform and constant boiling without hydraulic shocks (small boiling stones made of ceramic or glass are added to the flask to prevent bumping; in case of hydraulic shocks during boiling, a small amount of distilled water should be added to the flask to normalize the boiling process). Distillation is continued until there is no further delivery of water with oily droplets of P2P into the receiving flask. Fig 3

Appearance of P2P in the distillation flask during the process. Fig 4

In the distillation flask, heavy insoluble impurities remain at the bottom. Fig 5

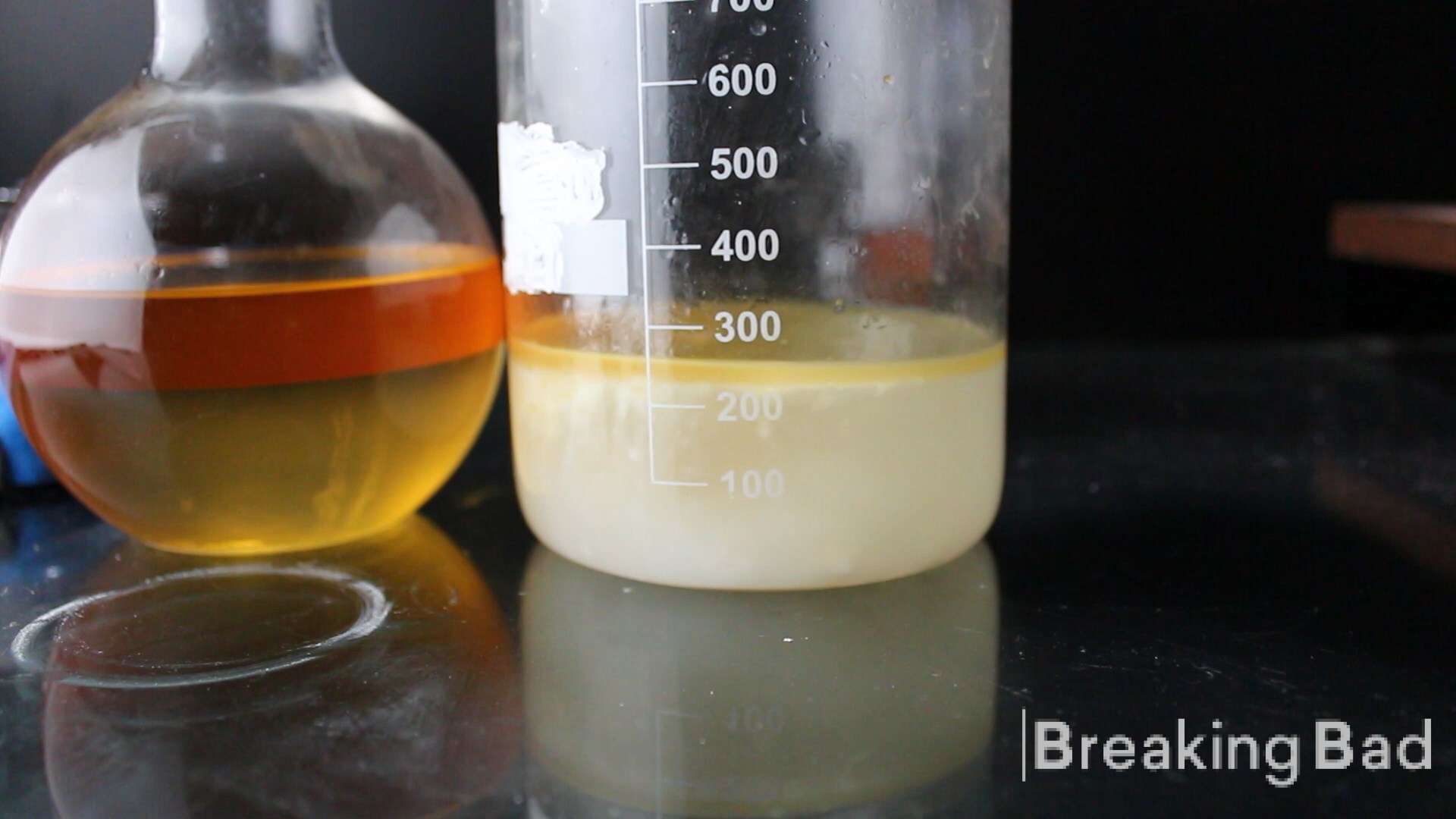

The water distilled along with P2P. Fig 6

A solution of sodium chloride is prepared to facilitate the upward floating of P2P and to enhance the separation process. The distilled water with P2P is poured into a large separatory funnel, and the prepared sodium chloride solution is added. Emulsions are allowed to settle for a certain period (at least a couple of hours). The lower aqueous layer is then drained because it contains a small residual amount of emulsified phenylacetone, which can be reused for distillation with new portions of P2P. Fig 7

The layer containing P2P is drained into a container with silica gel for drying and further use. Fig 8

The obtained P2P is a product with a purity of not less than 99%. The distillation process takes 2 days, and the yield is 100.02 grams, which corresponds to 68.98%. Fig 9

The bisulfite derivative of P2P is obtained by adding dirty P2P (without solvents) to an equal volume of concentrated sodium bisulfite with very intense stirring until complete crystallization. Fig 11

The bisulfite derivative of P2P is insoluble in diethyl ether, making it easy to wash away impurities. It can also be rapidly washed with butanol, in which the bisulfite derivative of P2P is also poorly soluble. However, due to the acidic properties of alcohols, decomposition will occur with the release of P2P, which will need to be separated again from the mother liquors. After washing, the bisulfite derivative of P2P is added to a solution of potassium or sodium carbonate, where P2P is liberated and can be separated from the alkaline solution, washed with an aqueous solution of sodium chloride, filtered if necessary, and dried with silica gel. Fig 12

- 145 ml of unrefined P2P obtained through the reduction of P2NP with borohydride

- 300-400 ml of a 10% aqueous solution of potassium carbonate

- 4 liters of distilled water

- 500 ml (100 g of sodium chloride) of a 20% aqueous solution of sodium chloride

- 1-liter, 2-liter, 500 ml, and 250 ml flasks

- Beakers

- Funnel

- 2-liter separatory funnel

- Ball-shaped condenser

- Glass adapters

- Teflon steam tube

- Heater

Steam P2P Distillation as a Purification Method

Steam P2P Distillation as a Purification Method...

Steam P2P Distillation as a Purification Method

Steam P2P Distillation as a Purification Method...

Performing the purification process of P2P through steam distillation

The flask for steam distillation is filled with P2P to be purified, and then it is half-filled with a pre-prepared solution of potassium carbonate. Fig 1A steam condenser is connected, and the entire setup for steam distillation is assembled. The amount of steam from the steam generator should be greater than what would be produced during the regular boiling of the P2P in the flask (i.e., the flask containing P2P should be smaller in volume than the steam generator). Fig 2

The mass in the distillation flask is adjusted to achieve a uniform and constant boiling without hydraulic shocks (small boiling stones made of ceramic or glass are added to the flask to prevent bumping; in case of hydraulic shocks during boiling, a small amount of distilled water should be added to the flask to normalize the boiling process). Distillation is continued until there is no further delivery of water with oily droplets of P2P into the receiving flask. Fig 3

Appearance of P2P in the distillation flask during the process. Fig 4

In the distillation flask, heavy insoluble impurities remain at the bottom. Fig 5

The water distilled along with P2P. Fig 6

A solution of sodium chloride is prepared to facilitate the upward floating of P2P and to enhance the separation process. The distilled water with P2P is poured into a large separatory funnel, and the prepared sodium chloride solution is added. Emulsions are allowed to settle for a certain period (at least a couple of hours). The lower aqueous layer is then drained because it contains a small residual amount of emulsified phenylacetone, which can be reused for distillation with new portions of P2P. Fig 7

The layer containing P2P is drained into a container with silica gel for drying and further use. Fig 8

The obtained P2P is a product with a purity of not less than 99%. The distillation process takes 2 days, and the yield is 100.02 grams, which corresponds to 68.98%. Fig 9

Purification methods of P2P

During the production of P2P, especially when using unrefined starting reagents and solvents, there will be constant challenges in conducting further syntheses and, most importantly, in obtaining the desired product yield. To achieve the desired synthesis results, it is necessary to purify the initial P2P from impurities.

There are several methods for purifying P2P from its impurities, including purification through the bisulfite derivative and simple steam distillation. Each of these methods is suitable for specific working conditions.

Bisulfite Method. It involves P2P selectively reacting with sodium bisulfite, forming a compound in the form of a crystalline creamy mass. Fig 10

There are several methods for purifying P2P from its impurities, including purification through the bisulfite derivative and simple steam distillation. Each of these methods is suitable for specific working conditions.

Bisulfite Method. It involves P2P selectively reacting with sodium bisulfite, forming a compound in the form of a crystalline creamy mass. Fig 10

The bisulfite derivative of P2P is obtained by adding dirty P2P (without solvents) to an equal volume of concentrated sodium bisulfite with very intense stirring until complete crystallization. Fig 11

The bisulfite derivative of P2P is insoluble in diethyl ether, making it easy to wash away impurities. It can also be rapidly washed with butanol, in which the bisulfite derivative of P2P is also poorly soluble. However, due to the acidic properties of alcohols, decomposition will occur with the release of P2P, which will need to be separated again from the mother liquors. After washing, the bisulfite derivative of P2P is added to a solution of potassium or sodium carbonate, where P2P is liberated and can be separated from the alkaline solution, washed with an aqueous solution of sodium chloride, filtered if necessary, and dried with silica gel. Fig 12

The P2P obtained by this method meets the commercial specifications stated in the Safety Data Sheet (SDS).

The processes of P2P interaction with sodium bisulfite and the interaction of the bisulfite derivative with carbonate proceed according to Scheme 1.

The processes of P2P interaction with sodium bisulfite and the interaction of the bisulfite derivative with carbonate proceed according to Scheme 1.

A drawback of this method is the problematic crystallization, especially for large volumes exceeding 1 liter. Additionally, obtaining sodium bisulfite and washing the obtained derivative can be challenging when using alcohols. The yields when using alcohols are 40-50% of pure P2P, and it also requires re-isolation from mother liquors.

Steam distillation. Steam distillation is a simple but time-consuming method for purifying high-boiling substances. In this study, heavily contaminated P2P, obtained from the unre-crystallized P2NP through sodium borohydride reduction, was purified using steam distillation. Steam distillation of the unrefined P2P is recommended to be conducted in the presence of potassium carbonate for additional impurity removal.

The distillation process can be intensified by using steam generators with at least a small pressure and volumetric capacity. For continuous and constant production, the distilled water (if no color change and impurities are present) separated from P2P is recommended to be recycled back to the distillation cycle for preparing the potassium carbonate solution, reducing overall losses of expensive and scarce P2P.

During the design of a steam distillation setup for large volumes of P2P (5 liters and above), the throughput capacity of the condenser should be carefully considered to avoid pressure fluctuations from the steam generator that could lead to explosions.

P2P obtained by Steam distillation method has a purity of not less than 99%. The yield of P2P is 68%.

When combining methods by obtaining the bisulfite derivative, followed by its decomposition with a potassium carbonate solution and steam distillation, P2P purity of 99.9% or higher can be achieved, but yield of P2P is 40-50%. This was confirmed by appropriate analytical methods such as TLC and refractometry. Fig 13

Steam distillation. Steam distillation is a simple but time-consuming method for purifying high-boiling substances. In this study, heavily contaminated P2P, obtained from the unre-crystallized P2NP through sodium borohydride reduction, was purified using steam distillation. Steam distillation of the unrefined P2P is recommended to be conducted in the presence of potassium carbonate for additional impurity removal.

The distillation process can be intensified by using steam generators with at least a small pressure and volumetric capacity. For continuous and constant production, the distilled water (if no color change and impurities are present) separated from P2P is recommended to be recycled back to the distillation cycle for preparing the potassium carbonate solution, reducing overall losses of expensive and scarce P2P.

During the design of a steam distillation setup for large volumes of P2P (5 liters and above), the throughput capacity of the condenser should be carefully considered to avoid pressure fluctuations from the steam generator that could lead to explosions.

P2P obtained by Steam distillation method has a purity of not less than 99%. The yield of P2P is 68%.

When combining methods by obtaining the bisulfite derivative, followed by its decomposition with a potassium carbonate solution and steam distillation, P2P purity of 99.9% or higher can be achieved, but yield of P2P is 40-50%. This was confirmed by appropriate analytical methods such as TLC and refractometry. Fig 13

Spoiler:

The release of P2P steam distillation video is expected very soon! The video materials are already being edited!!!

Last edited by a moderator: