WillD

Expert

- Joined

- Jul 19, 2021

- Messages

- 645

- Reaction score

- 901

- Points

- 93

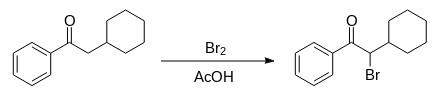

2-Bromo-2-cyclohexyl-1-phenylethanone.

1. 1000 g of 2-cyclohexyl-1-phenylethanone and 3000 ml of acetic acid were mixed in the reactor.

2. Turned off stirring and left during at room temperature.

3. The pure bromine (800 g) was neatly poured into the reactor and left in a mixture without stirring.

4. After some time, the reaction autorun occurred, severe hydrobromic acid gas leading.

5. Gas is bubbled into a mixture with absorbent (aqueous solution of sodium hydroxide, 400 g for the whole amount of water).

6. When reducing the rapid evolution of gas began stirring cautious.

7. At the end of the gas is released, and the reaction has cooled to room temperature (crystallization may start), 9000 ml of pure cold water slowly poured (сrystals are formed).

8. After 15 minutes, stirring stopped, the sediment of the bromoketone was fall on the bottom (yellow solid).

9. The water layer was separated through the top of the reactor and was re-washed with a saturated solution of soda, and clean water.

10. Used in subsequent reactions without further purification, yield: 1300 g.

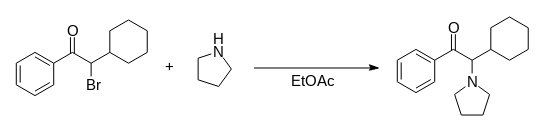

2-Cyclohexyl-1-phenyl-2-(pyrrolidin-1-yl)ethanone Hydrochloride.

1. Added 4 litres ethyl acetate in the reactor and stirring 5 minutes.

2. Added 1000 g pyrrolidine into the drop funnel and mounted on the reactor cover.

3. Open tap drop funnel and added pyrrolidine dropwise, with intense stirring.

4. Check temperature below 65 *C.

5. After all pyrrolidine added, inteximally stirred 1 hour.

8. Turn on reactor vacuum pump and chiller pump for reactor condenser.

9. Distilled all or most amount of ethyl acetate.

10. Stop vacuum pump and added in the reactor acetone. Stirring continues.

11. Added hydrochloric acid into the drop funnel and mounted on the reactor cover.

12. Dropwise acid to pH - 5. Drain a small amount from the bottom reactor tap and control the level of acidity with a litmus strip. Return the sample to the reaction mixture.

13. After that, poured all mixture in bucket and put in the freezer for 12 hours.

14. Installed by vacuum filtration system (nutsche filter, filter cloth, vacuum pump).

15. Start vacuum pump.

16. Pour a bucket from step 13 to the filter bowl.

17. Filter and press until the mixture of the bowl becomes solid.

18. Pour cold acetone into the bowl to cover the whole solid from above.

19. Filter all acetone. Repeat step 18 if the solid is not white.

20. After filtered all acetone and achieving white solid, put the contents of the bowl in the glass containers for drying.

21. Put the glass containers on racks at room temperature.

22. Dry to constant mass. Periodically mix and grind, for faster drying.

1. 1000 g of 2-cyclohexyl-1-phenylethanone and 3000 ml of acetic acid were mixed in the reactor.

2. Turned off stirring and left during at room temperature.

3. The pure bromine (800 g) was neatly poured into the reactor and left in a mixture without stirring.

4. After some time, the reaction autorun occurred, severe hydrobromic acid gas leading.

5. Gas is bubbled into a mixture with absorbent (aqueous solution of sodium hydroxide, 400 g for the whole amount of water).

6. When reducing the rapid evolution of gas began stirring cautious.

7. At the end of the gas is released, and the reaction has cooled to room temperature (crystallization may start), 9000 ml of pure cold water slowly poured (сrystals are formed).

8. After 15 minutes, stirring stopped, the sediment of the bromoketone was fall on the bottom (yellow solid).

9. The water layer was separated through the top of the reactor and was re-washed with a saturated solution of soda, and clean water.

10. Used in subsequent reactions without further purification, yield: 1300 g.

2-Cyclohexyl-1-phenyl-2-(pyrrolidin-1-yl)ethanone Hydrochloride.

1. Added 4 litres ethyl acetate in the reactor and stirring 5 minutes.

2. Added 1000 g pyrrolidine into the drop funnel and mounted on the reactor cover.

3. Open tap drop funnel and added pyrrolidine dropwise, with intense stirring.

4. Check temperature below 65 *C.

5. After all pyrrolidine added, inteximally stirred 1 hour.

8. Turn on reactor vacuum pump and chiller pump for reactor condenser.

9. Distilled all or most amount of ethyl acetate.

10. Stop vacuum pump and added in the reactor acetone. Stirring continues.

11. Added hydrochloric acid into the drop funnel and mounted on the reactor cover.

12. Dropwise acid to pH - 5. Drain a small amount from the bottom reactor tap and control the level of acidity with a litmus strip. Return the sample to the reaction mixture.

13. After that, poured all mixture in bucket and put in the freezer for 12 hours.

14. Installed by vacuum filtration system (nutsche filter, filter cloth, vacuum pump).

15. Start vacuum pump.

16. Pour a bucket from step 13 to the filter bowl.

17. Filter and press until the mixture of the bowl becomes solid.

18. Pour cold acetone into the bowl to cover the whole solid from above.

19. Filter all acetone. Repeat step 18 if the solid is not white.

20. After filtered all acetone and achieving white solid, put the contents of the bowl in the glass containers for drying.

21. Put the glass containers on racks at room temperature.

22. Dry to constant mass. Periodically mix and grind, for faster drying.

Last edited by a moderator: