G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,704

- Solutions

- 3

- Reaction score

- 2,857

- Points

- 113

- Deals

- 1

Introduction

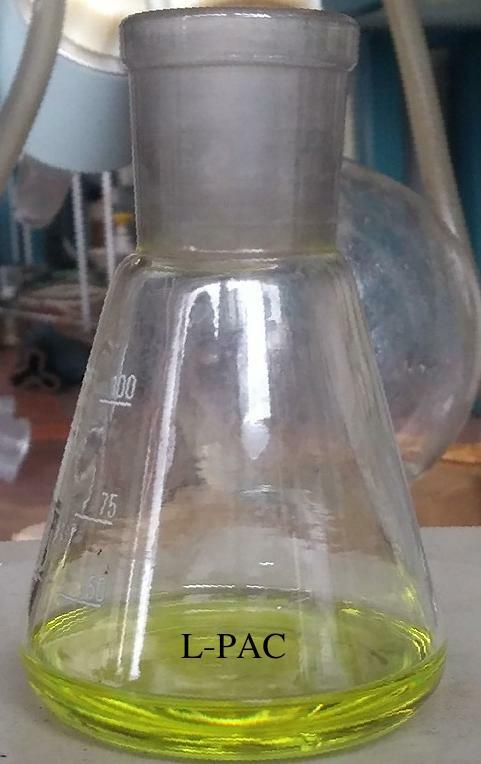

L-Ephedrine is obtained from dried plants of various species of the genus Ephedra by initial treatment with alkali, followed by extraction with organic solvent. Extraction, purification and isolation of these drugs is time-consuming, costly and complicated by the presence of undesired byproducts. L-Phenylacetylcarbinol (L-PAC; (1)) which is a precursor for ephedrine is produced by biotransformation of benzaldehyde using yeast cultures. The chemical conversion of L-PAC to ephedrine has proved to be more advantageous than the extraction route. L-PAC could be converted by a chemical reductive amination with methylamine to optically pure L-ephedrine. The use of microwave irradiation for chemical synthesis is of increasing importance, since it provides a simple alternative to classical chemical routes with rapid reactions yielding high conversion and selectivity. The present work was undertaken to explore the possibility of conducting the synthesis using microwaves as an alternative to these routine chemical synthetic reactions. A two-step simple synthetic reaction was carried out in a homogeneous reaction medium under exposure to microwaves. A homogeneous reaction medium ensures better thermal homogeneity under microwave heating and facilitates scale-up of the reaction. The procedure is superior to methods involving complex hydrogenation procedures and those involving reduction of protected cyanohydrins. Also, you can read other topics concerns ephedrine manufacturing.

Equipment and glassware:

- 100 mL Round-bottom flask;

- Ice;

- pH indicator paper;

- Paster pipete;

- 100 mL Drip funnel with equalize pressure;

- Retort stand and clamp for securing apparatus;

- Magnetic stirrer;

- 100 mL x4; 50 mL x2 Beakers;

- 500 mL Separatory funnel;

- Calcium chloride (CaCl2) tube;

- Flash chromatography kit (middle column and silica gel 60 ± 120 mesh);

- IFB Neutron kitchen oven (760 W output and 2450 MHz frerequest);

- Vacuum source;

- Glass rod and spatula;

- Rotovap machine;

- Laboratory scale (0.01-100 g is suitable) [depends on synthesis load];

- Measuring cylinder, 100 mL.

Reagents:

- L-PAC (0.03 moles, 4.5 g) [CAS Number 1798-60-3];

- Ethanol (EtOH) ~150 mL;

- Hydrochloric acid conc. (HCl) aq. solution ~20 mL;

- Methylamine 40% (v/v) solution (CH3NH2) 9 mL;

- Diethyl ether (Et2O) 200 mL;

- Sodium bicarbonate (NaHCO3) ~50 g;

- Distilled water, 65 mL;

- Sodium sulphate anhydrous (Na2SO4) or magnesium sulfate (MgSO4) ~100 g;

- Ethyl acetate (EtOAc) ~500 mL;

- Toluene ~400 mL

- Sodium borohydride (NaBH4) 0.09 moles, 3.24 g.

Procedure

Conversion of L -phenylacetylcarbinol (L -PAC) (B) to 2-(methylimino)-1-phenyl-1-propanol (2)L -PAC (0.03 moles, 4.5 g) was placed in a 100 mL round-bottom flask containing 10 mL of ethanol, cooled in crushed ice and the pH adjusted to 4, by dropwise addition of conc. HCl. Three mL of a 40% (v/v) solution of methylamine was added dropwise with constant stirring. The reaction mixture was brought to ambient temperature (30 +/- 2 °C) and was irradiated for 3 min at 50 % power in a modified domestic microwave* oven in previous flask with CaCl2 tube (connection with atmosphere). The reaction was further continued for 6 min (two cycles of 3 min at 50 % power) with addition of 3 mL 40 % methylamine solution during each irradiation cycle. After exposure to the microwaves, the reaction mixture was cooled in crushed ice with 10 mL of added water. The pH of the reaction mixture was adjusted to 4 and the reaction mixture was washed with ether (25 mL x 3) to collect unreacted L-PAC (1). The aqueous layer was neutralized with NaHCO3 and the pH value adjusted to between 7 and 8. The aqueous layer was extracted with ether (25 mL x 3) and the combined ether layers were washed again with 15 mL of cold water. The ether layer was dried by passing through anhydrous sodium sulphate (Na2SO4); ether was removed in a rotavap to obtain the product (2) as a yellow oil. This oil was further purified by silica gel (60 ± 120 meshes) column (flash) chromatography using ethyl acetate and toluene (6:4) as eluent. Yield 55 %.

*For chemical reactions using microwave irradiation, a modified IFB Neutron kitchen oven (760 W output and 2450 MHz frerequest) was used.

*For chemical reactions using microwave irradiation, a modified IFB Neutron kitchen oven (760 W output and 2450 MHz frerequest) was used.

2-(methylamino)-1-phenyl-1-propanol (3) (Ephedrine)

The imine (2) 2-(methylimine)-1-phenyl-1-propanol (0.03 moles, 4.89 g) was placed in a 100 mL round-bottom flask containing 10 mL of ethanol. To this solution NaBH4 (0.09 moles, 3.24 g) was added in increments of 0.02 moles for each microwave irradiation of 2 min at 50 % power. The total reaction time under microwave exposure was 10 min (2 min x five cycles of 50 % power). After exposure to the microwaves, the reaction mixture was cooled in ice and quenched by adding 10 mL of ice-cold water and some pieces of ice. This solution was then extracted with ether (25 mL x 3). The combined ether layers were washed twice with 15 mL of cold water in a separatory funnel and dried by passing through anhydrous sodium sulphate (Na2SO4) in a beaker. The ether layer was removed in a rotavap to give the oil containing product and unreacted imine (2). The mixture was separated by column chromatography using silica gel (60 ± 120 mesh) and ethyl acetate±toluene (8:2) as eluent. The isolated product obtained after elution of the column was recrystallized in hot ethanol and dried to give ephedrine. Yield 64 %.

The imine (2) 2-(methylimine)-1-phenyl-1-propanol (0.03 moles, 4.89 g) was placed in a 100 mL round-bottom flask containing 10 mL of ethanol. To this solution NaBH4 (0.09 moles, 3.24 g) was added in increments of 0.02 moles for each microwave irradiation of 2 min at 50 % power. The total reaction time under microwave exposure was 10 min (2 min x five cycles of 50 % power). After exposure to the microwaves, the reaction mixture was cooled in ice and quenched by adding 10 mL of ice-cold water and some pieces of ice. This solution was then extracted with ether (25 mL x 3). The combined ether layers were washed twice with 15 mL of cold water in a separatory funnel and dried by passing through anhydrous sodium sulphate (Na2SO4) in a beaker. The ether layer was removed in a rotavap to give the oil containing product and unreacted imine (2). The mixture was separated by column chromatography using silica gel (60 ± 120 mesh) and ethyl acetate±toluene (8:2) as eluent. The isolated product obtained after elution of the column was recrystallized in hot ethanol and dried to give ephedrine. Yield 64 %.

Last edited by a moderator: