William D.

Expert

- Joined

- Jul 19, 2021

- Messages

- 1,055

- Reaction score

- 1,324

- Points

- 113

MDMA Synthesis From Safrole Review

Main topic about synthesis way...

Firstly, I'm going to tell you if you would want to make MDMA, you would need a source of safrole, you could get this from a chemical company or distill it out of sassafras oil.

Via the chemical company is not an option for 99/100 people, so that's why I'm going to tell you how to distill it out of sassafras oil.

Sassafras oil itself is even hard to get by, but after searching for a very,very,very long time you will eventually find it, hopefully.

I'm not going to tell you where to find it or how to find it, just only use this book when you already have a bottle of sassafras oil lying around.

Well, to the distilling now.

In the picture below you can see a distillation setup, there is no vacuum used when distilling safrole this worked out just fine.

Pour the sassafras oil in the distillation flask, and put the flask in a heating mantle or another heating source.

Here below you can see a bottle of sassafras oil and a distillation setup which is distilling sassafras oil.

On the bottom left you can see the heating mantle it is also covered on top with alluminiumfoil, to prevent a lot of heat to escape.

The whole vigreux colomn is also packed with alluminiumfoil on the outside, else the heat will not propogate to the thermometer and the distilling head.

The thicker glass tube you see standing in the slope, is the cooler, ICE cold water is floating through the double glass wall, and through the glass spiral, this is to make the evaporated safrole condensate again.

The vigreux colomn is used to get a more pure product, and it also is nice to be there, because when distilling the oil it, the oil will bump very hard in the flask.

It might even scare you for the first time.

It needs to be 230 *C in the top of the distilling head, it is suggested to use boiling stones in the flask to calm the bumping down a bit.

Do not close the setup completely else there will be too much pressure inside, as you can see on the right of the picture there is another flask and on top of that flask there is a piece of glass which is bent it is called an allonge it has a vacuum adapter piece to it.

If you do have a vacuum source, you can connect your vacuum tube to that piece of glass. Now it functions as a pressure release opening.

Here you can see the temperature going over 200 *C.

Here you can see the pure safrole in the flask which came over, it is water-white oil.

Out of 90 ml of sassafras oil, 75 ml of safrole is distilled out. On the right, you see the tar and rest of the crap that is left in the distillation flask, this stuff doesn't come over, so apparently it will be a chemical that we have a boiling point greater than 300 *C.

Via the chemical company is not an option for 99/100 people, so that's why I'm going to tell you how to distill it out of sassafras oil.

Sassafras oil itself is even hard to get by, but after searching for a very,very,very long time you will eventually find it, hopefully.

I'm not going to tell you where to find it or how to find it, just only use this book when you already have a bottle of sassafras oil lying around.

Well, to the distilling now.

In the picture below you can see a distillation setup, there is no vacuum used when distilling safrole this worked out just fine.

Pour the sassafras oil in the distillation flask, and put the flask in a heating mantle or another heating source.

Here below you can see a bottle of sassafras oil and a distillation setup which is distilling sassafras oil.

On the bottom left you can see the heating mantle it is also covered on top with alluminiumfoil, to prevent a lot of heat to escape.

The whole vigreux colomn is also packed with alluminiumfoil on the outside, else the heat will not propogate to the thermometer and the distilling head.

The thicker glass tube you see standing in the slope, is the cooler, ICE cold water is floating through the double glass wall, and through the glass spiral, this is to make the evaporated safrole condensate again.

The vigreux colomn is used to get a more pure product, and it also is nice to be there, because when distilling the oil it, the oil will bump very hard in the flask.

It might even scare you for the first time.

It needs to be 230 *C in the top of the distilling head, it is suggested to use boiling stones in the flask to calm the bumping down a bit.

Do not close the setup completely else there will be too much pressure inside, as you can see on the right of the picture there is another flask and on top of that flask there is a piece of glass which is bent it is called an allonge it has a vacuum adapter piece to it.

If you do have a vacuum source, you can connect your vacuum tube to that piece of glass. Now it functions as a pressure release opening.

Here you can see the temperature going over 200 *C.

Here you can see the pure safrole in the flask which came over, it is water-white oil.

Out of 90 ml of sassafras oil, 75 ml of safrole is distilled out. On the right, you see the tar and rest of the crap that is left in the distillation flask, this stuff doesn't come over, so apparently it will be a chemical that we have a boiling point greater than 300 *C.

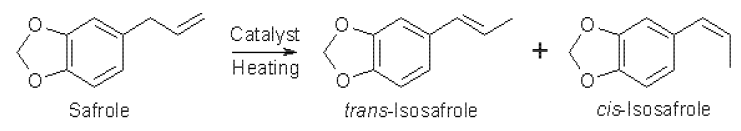

Now that we have the pure safrole, we can start with the next step. Isomerizing the safrole to isosafrole.

Safrole itself looks like this:

Many ways of isomerizing safrole (3,4-Methylenedioxyallylbenzene) into isosafrole (3,4- Methylenedioxy- propenylbenzene) can be found in the literature. The isomerizations, which in all reviewed cases are catalytic, often have high yields, but differs greatly in easiness and reaction times. Though availability and costs of the catalysts also differ over a broad range.

The reaction, which is general for the conversion of nearly all allylbenzenes (like safrole, apiole, dillapiole and elemicin) to their corresponding propenylbenzene isomer, is usually carried out by heating the allylbenzene together with an inorganic catalyst or catalyst mixture under reflux, with or without the use of a solvent. After the reaction is finished, the catalyst is removed by filtration, any solvent removed under vacuum, and the residue is distilled to purify the propenylbenzene from unreacted allylbenzene and polymerized material.

21,10 grams of KOH weighed down.

Glassware set up for reflux.

Reflux means that the cooler is put inside the flask upside down, and so when there are chemicals in the flask that can evaporate easily, they would normally evaporate and be gone out of the reaction when you heat it to let them react.

If you would placed a cooler on top of the flask, the chemicals which evaporate will cool down again and fall back down in the reaction flask.

That is in short the principle of refluxing.

The person who did this synthese let s call him SWIM poured the 75 ml safrole in the flask.

He added to this 30 ml 96% ethanol and 21,10 g of KOH.

SWIM refluxed it for 3-4 hours on a gentle reflux of 60 *C.

After adding the KOH to the safrole+ethanol, the mixture turned brown.

1 minute 1,5 hour 4 hours.

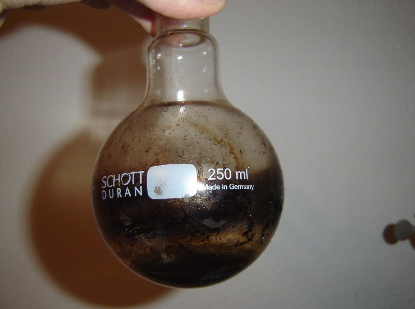

This is what was left after refluxing it, on the bottom is a hard cake of KOH lying.

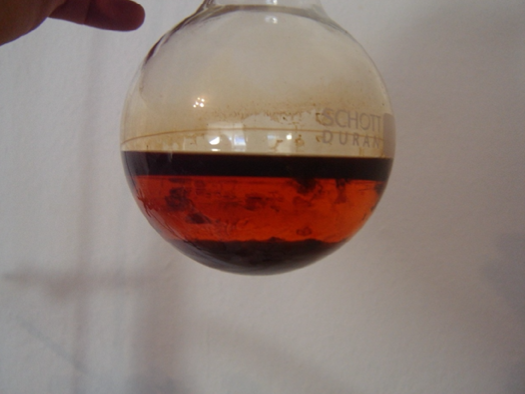

This mixture was filtrated to get rid of the solid KOH. This is what the filtrate looks like.

Here you can see the KOH cake on the bottom of the flask which is left.

Toluene is poured into the sludge which remains and threw the filter to get all the isosafrole out of there.

Toluene doesn't mix with water, it has a lower density (0,86 g/ml), so it floats on top of water.

Drain off the water layer, and keep the toluene layer, add this to the filtrate and distill it to get rid of the red/brown color, but before you distill it, you need to neutralise the KOH with an acid, SWIM used H2SO4 diluted in water to 50% and checked it with pH paper to get it only a bit basic.

This is what is left after distilling the isosafrole, the yield was 80% by weight. It was 66 ml.

Safrole itself looks like this:

Many ways of isomerizing safrole (3,4-Methylenedioxyallylbenzene) into isosafrole (3,4- Methylenedioxy- propenylbenzene) can be found in the literature. The isomerizations, which in all reviewed cases are catalytic, often have high yields, but differs greatly in easiness and reaction times. Though availability and costs of the catalysts also differ over a broad range.

The reaction, which is general for the conversion of nearly all allylbenzenes (like safrole, apiole, dillapiole and elemicin) to their corresponding propenylbenzene isomer, is usually carried out by heating the allylbenzene together with an inorganic catalyst or catalyst mixture under reflux, with or without the use of a solvent. After the reaction is finished, the catalyst is removed by filtration, any solvent removed under vacuum, and the residue is distilled to purify the propenylbenzene from unreacted allylbenzene and polymerized material.

21,10 grams of KOH weighed down.

Glassware set up for reflux.

Reflux means that the cooler is put inside the flask upside down, and so when there are chemicals in the flask that can evaporate easily, they would normally evaporate and be gone out of the reaction when you heat it to let them react.

If you would placed a cooler on top of the flask, the chemicals which evaporate will cool down again and fall back down in the reaction flask.

That is in short the principle of refluxing.

The person who did this synthese let s call him SWIM poured the 75 ml safrole in the flask.

He added to this 30 ml 96% ethanol and 21,10 g of KOH.

SWIM refluxed it for 3-4 hours on a gentle reflux of 60 *C.

After adding the KOH to the safrole+ethanol, the mixture turned brown.

1 minute 1,5 hour 4 hours.

This is what was left after refluxing it, on the bottom is a hard cake of KOH lying.

This mixture was filtrated to get rid of the solid KOH. This is what the filtrate looks like.

Here you can see the KOH cake on the bottom of the flask which is left.

Toluene is poured into the sludge which remains and threw the filter to get all the isosafrole out of there.

Toluene doesn't mix with water, it has a lower density (0,86 g/ml), so it floats on top of water.

Drain off the water layer, and keep the toluene layer, add this to the filtrate and distill it to get rid of the red/brown color, but before you distill it, you need to neutralise the KOH with an acid, SWIM used H2SO4 diluted in water to 50% and checked it with pH paper to get it only a bit basic.

This is what is left after distilling the isosafrole, the yield was 80% by weight. It was 66 ml.

Firstly, you need DCM (dichloromethane aka methylenechloride) it is sold as paintstripper and as brush de-hardener.

In the country where SWIM lives, they only sell paint stripper with a wax binder which sucks, so he found that the brush de-hardener didn't contain any wax binder, so he distilled the brush de-hardener.

It contains: DCM, methanol, solvent-naphta, hydrogenated naptha.

Both the napthas have a boiling point greater than 100 *C, the methanol 65 *C and the DCM 39-40 *C.

So without a vigreux colomn he distilled the DCM, and it came over at 39 *C until 41 *C.

The mixture itself was 55*C and the gastemperature was 39 *C and at the end 41 *C the mixture contained 65% DCM.

The addition funnel is to get the DCM in the 1 liter round bottom flask.

All the DCM is added to the flask (500 ml) and it is ready for the heating, so SWIM turned on the heat and started to distill off the DCM.

Boiling brush de-hardener.

Quite some DCM came over quickly, at least enough to use as a solvent for the epoxidation reaction.

To do the peracetic acid epoxidation reaction, the isosafrole needs to be dissolved in a solvent to make it mix with the peracid, alcohol can be used, but due to alcohol containing water easily it is not a good choice. Acetone is also quite a lot used, but SWIM didn't want to use it, because you need to distill the mixture after you are done with the MDP2P reaction.

And acetone can form acetone peroxide with hydrogen peroxide and an acid (acts as a catalyst). Acetoneperoxide is a high explosive, which detonates from heat.

So guess what happens if you used a bit too much H2O2, and then you are going to distill that mixture Acetoneperoxide are white needle like crystals by the way.

Anyway, to make the peracid one should do the following:

Pour:

- 55,8 ml of 99-100% glacial acetic acid

- 55,2 ml hydrogen peroxide 35%

- 0,66 ml sulfuric acid 96%

H2O2 and acetic acid.

Sulfuric acid 96% with a 1,00 ml pipette.

Everything mixed, set this aside for 4 days, and swirl every day for a couple of times.

All together in a flask, let this react for 4 days, it doesn't heat up, just stink like acetic acid very badly. And let it react for 4 days to get to it s equilibrium, and then it can be used.

Dissolve 33 ml of isosafrole in 51 ml DCM.

Add this slowly to the peracetic acid, and let the temperature not rise over 40 *C.

You should place the flask on a magnetic stirrer in an icebath while doing this.

After everything is added, let the ice-bath come to roomtemperature by itself, and leave it to stirr overnight, with some foil over the top of the flask.

The color will go from yellow to orange to deep red, distill off the DCM and distill off the acetic acid.

A dark, thick syrup will remain.

Dissolve this syrup in 51 ml methanol and add to this 250 ml 15% H2SO4 solution.

Let this reflux mildly for 3 hours.

Then when it has come to room temperature, drain off the acid layer, and keep the dark layer.

Pour the dark layer in 125 ml of water and then extract the syrup again.

Then wash it with 125 ml of NaOH solution of 5%, this last wash is difficult to see so use a flashlight to see where the phases separate.

Now pour in 5 g of MgSO4 (epsomsalt) which is completely dry, dried in oven at 300 *C for 4 hours.

Filter off the MgSO4 again and wash the MgSO4 with DCM.

Distill the resulting liquid, this is your pure ketone.

Here are the pictures:

Here you can see 51 ml of dichloromethane mixed with 33 ml of safrole, it does not mix when just poured onto each other, SWIM sucked the mixture up with his pipette and blew it back into the rest of the liquid to mix it, until it was mixed well, it was quite easy to mix.

Here you can see the icebath with the isosafrole and DCM mixed in there, while the peracetic acid is being added to it slowly.

As you can see, it is in an icebath as mentioned above, this is to prevent the liquid becoming too hot, and get to a boil.

Although it should not exceed 40 *C, DCM is used as a solvent, so you also need not worry about explosives peroxides(since you need to distill this mixture) when using acetone make sure you do not add too much H2O2, since if not everything is used up by the acid it will peroxidize your solvent if it is peroxidizable (such as ether and acetone).

Below you can see the color change, the first picture is after everything is just added, the 2nd after an hour and the third after 2 hours and so on, on the third it is capped with Al foil, and left to stir for 16 hours.

As you can see, the color changes from clear to yellow to orange to red to dark black-red.

Now the 16 hours has passed.

It is time for the DCM to be distilled off.

Thus SWIM poured his mixture in another round bottom flask and set it up for distillation, see below.

The color is like orange juice, in some syntheses it is said to be dark red.

Well, this is what happened in the epoxidation reaction:

When the peracid forms this happens in general:

Now it is time to get rid of the acid, that is done by adding NaOH solution SWIM used around 3 g of NaOH in 150 ml water, and used it all to neutralise the peracetic acid he made. Below you can see pictures of a wash with ether after it was neutralised, this was done twice.

You can see the layers quite badly, although you can see an upper layer which is slightly darker than the other layer, ether will float on top since the density is a lot lower than that of water.

Here it is separated by a separatory funnel, here again it isn't seen well, but the layer is underneath the text 250 ml in blue on top of the funnel, not where the big part goes over in the smaller part.

Here is a close up of the ether(which contains your isosafrole glycol) layer and the water with sodiumacetate layer.

The peracetic acid gets neutralised with NaOH so it forms water and sodiumacetate.

Anyway, the layer on the bottom can be getting rid of, but SWIM washed it again with ether and combined that ether layer with the previous ether layer, the one that is on top in the picture above.

The ether is distilled off at 39*C, and pure isosafrole glycol is what you have in the flask then. This needs to be turned into MDP2P, you can see the reaction mechanism below.

You need to pour as much methanol together with the isosafrole glycol, as you used solvent for the isosafrole.

In SWIM's case that was 51ml, so now he uses 51ml methanol to dissolve the isosafrole glycol in, and adds 255 ml (5 times as much as the methanol) 15% H2SO4 to it.

If you take 99% sulfuric acid, that is the most common to buy as draincleaner, one could also buy battery acid. That is 37.5% sulfuric acid, dilute it 2,5 times with water to get 15%, but if you couldn't figure that out, you didn't get this far with the synthese, although you should read this whole thing before beginning anyway.

When using 99%, you need to dilute it 6,6 times.

When using 96% (also quite common instead of 99% as draincleaner), you need to dilute 6,4 times.

The density of H2SO4 when concentrated is 1,84 g/ml, so you need 1,84 g with 6,4 times as much water.

1,84 g*6,4 g = 11,78 g water. 11,78 g/0,998 g/ml = 11,80 ml water.

1,84 g = 1 ml

So for every milliliter H2SO4 you need 11,80 ml water.

You need 255 ml sulfuric acid, 255/11,80 ml = 21,61

((19,92*11,80)/0,998)= 234,53 ml = 234,06 g

((19,92* 1,84)/1,84) = 19,91 ml = 36,63 g

234,06 g / 36,63 g = 6,4 times as much.

This is what it looks like just plain, not with a lamp underneath it, this is only the first wash by the way. The next wash will be added to this, and then the ether is distilled off and the pure isosafrole glycol remains, and then you should add the methanol and the sulfuric acid (mix the sulfuric acid ahead with water).

Reflux this mixture for 3 hours and no longer else, the yield will go down, now you have raw MDP2P.

Now let it cool down to ROOM temperature, now pour off as much of the water as possible, and pour new fresh water in there, so the flask is filled half or 2/3rd and mix well, and let the layers separate and decant of the water.

Do this 4 times, this should be good enough to remove the last traces of sulfuric acid left in the oil.

Now, for the last time adding water decant off the water, and attach distill head etc. onto the flask, and start to distill the MDP2P.

From another synthese I read, the MDP2P comes over as a yellow to brown oil at 115-170*C with an aspirator vacuum, and then redistillation gives yellow oil (MDP2P) at 140-150*C.

At SWIM the MDP2P came over at 158 °C with vacuum, SWIM collected 15 g of MDP2P that is a yield of +/- 45%, which was yellow golden in color, and when held against the sunlight it has a greenish look from some sides depends on how one looks at it.

Another method to collect your MDP2P would be (and also to test if it is real MDP2P) with sodiumbisulfite.

One would make a saturated solution of sodiumbisulfite, and drop a bit of what should be MDP2P into it, and if a preticipate forms, it is a ketone, and most likely MDP2P, since it just happens to be a ketone.

It is a somewhat well known fact that sodium bisulfite will add to the carbonyl group of a ketone to form a crystalline addition product. If the parent ketone is of large enough molecular weight, the product will be insoluble in water. The parent ketone can then be recovered at a later time by decomposition with sodium hydroxide. This is a doubly good trick in that it gives us an excellent way to get pure ketone from an impure reaction matrix, and it also allows the long term storage of an otherwise unstable ketone prior to its use.

Now, this doesn't *eliminate* the need for a proper (vacuum) distillation of the ketone, but it does make such a process much more pleasant in that when recovering from the bisulfite, there will be little tar and/or polymerized crap to deal with. This means greatly reduced cleaning for those precious flasks, and, possibly, higher yields. The bisulfite addition is a fairly general process, and may be adapted to different ketones (keeping the molar ratios in proportion), however, there are going to be some ketones which will either not react or react to a low extent (mainly ones in which there is significant steric hindrance to the carbonyl carbon). In cases where the carbonyl carbon is on an aliphatic side chain to some other funky ring structure, there is little steric hindrance, and so the reaction proceeds quickly and nearly quantitatively. Finally, there is the limitation that ketone (or ketone containing slop) be reasonably freed of acidic or basic impurities, as these will interfere with the formation of the addition product.

1) Preparation of the bisulfite reagent

(This must be prepared just prior to use, as it will autooxidize within hours if left to it's own devices.)

Add 52 g sodium bisulfite (NaHSO3, .5 moles) to approximately 90 mL of distilled water at room temperature with vigorous stirring (slightly more water may be used to get it all into solution). Add a volume of denatured alcohol of about 70% of the solution's volume (i.e.- if you end up with 100 mL of solution, add 70 mL of alcohol), then add more water to just dissolve the precipitate (~60 mL).

2) Reacting with the ketone

Slowly drip .25 moles of ketone(*) into a beaker containing the bisulfite solution, with vigorous magnetic stirring. The 2:1 molar ratio insures that all the ketone will be converted. Let sit on the stirrer for an additional 30-45 minutes, then filter on a vacuum Buchner funnel. Wash the crystals with 20-50 mL of denatured alcohol. Dry in a vacuum dessicator or open tray, then store in a stoppered glass bottle until needed.

(*) If adding an impure reaction matrix, add as much solution as you expect to contain .25 moles of ketone.

3) Recovering the ketone

Add the ~.25 moles of bisulfite addition product to a separatory funnel, then slowly pour in 105 mL of 10% Sodium Hydroxide solution (w/w). Separate out the aqueous layer (which may be on top or on bottom depending on the ketone), saturate with salt (NaCl), and extract with 50 mL of ether (toluene or benzene ok if the ketone is of high enough bp). Combine the extract with the ketone layer and strip off the ketone by distillation (condense and reuse!). Distill the ketone residue, preferably under vacuum (if you're making what I think you're making), to yield up to 90%, depending on the purity of the starting ketone, of course.

Refs to chase: A. Vogel, "Practical Organic Chemistry"

Now one has MDP2P, if one wants to store it do so in the freezer it will become a very viscous liquid and will be storable for LONG times.

Now will be outlined how MDP2P, can be synthesized with the wacker oxidation and p-benzoquinone a la Methylman.

To convert safrole to MDP2P one does the following:

- Distilled sassafras oil to yield safrole 18ml

- 40 ml MeOH

- 0,2 g PdCl2

- 5 ml dH2O

- 15 g p-benzoquinone

First, let all the chemicals stirr themselves for an hour, except for the safrole, the safrole has to be added later on after everything has been mixed thoroughly for an hour.

Then start dripping in the safrole, this should take at least an hour, when dripping is at 80%, then start heating slowly and, after everything has been added, start a reflux for 8 hours.

After the 8 hours have passed, throw the whole reaction mixture through a buchner filter to filter out any residue like hydroquinone (degradation product of 1,4-benzoquinone) and PdCl2 (don't try to recover this, it is not worthwhile).

After filtration add 150 ml 10% HCl to hydrolyse the reaction to MDP2P, stirr for 15 minutes and now extract 3 times with 100 ml DCM, 50 ml and 25 ml DCM.

Combine extracts and wash them 2 times with 50 ml saturated sodiumbicarbonate solution, then 2 times with 50 ml saturated NaCl solution.

Then wash the extracts, which have now turned color a bit more greenish/yellow with 5-10% NaOH solution and do this 3 times with a volume of 100ml per wash, now dry the ketone after the NaOH solution has been drained off with MgSO4 or Na2SO4 (anhydrous).

And after it has been dried, distill off rotavap off the DCM and be left with impure MDP2P. This needs to be distilled and there are a few pictures of below:

This is the color of the MDP2P.

I've heard it smells like flowers, but I don't think it does, it doesn't even smell nice, it doesn't stink, but well, it's like safrole a bit, but then a bit more like flowers, then safrole, but not really like flowers, well anyway, smell it when you made it, and you know.

It has a greenish hue on it.

This is the reduction setup, but the same is the wacker oxidation since there is the safrole on the right and on the left the condenser for reflux and an overhead stirrer in the middle a heating mantle in the middle too, and in the back a bucket with 10 liters of cooling water.

After the MDP2P has distilled, one will have around 8 ml MDP2P to 15 ml.

SWIM got 8 ml it was the first time doing this reaction, but the yield will go up with more experience probably.

- Distilled sassafras oil to yield safrole 18ml

- 40 ml MeOH

- 0,2 g PdCl2

- 5 ml dH2O

- 15 g p-benzoquinone

First, let all the chemicals stirr themselves for an hour, except for the safrole, the safrole has to be added later on after everything has been mixed thoroughly for an hour.

Then start dripping in the safrole, this should take at least an hour, when dripping is at 80%, then start heating slowly and, after everything has been added, start a reflux for 8 hours.

After the 8 hours have passed, throw the whole reaction mixture through a buchner filter to filter out any residue like hydroquinone (degradation product of 1,4-benzoquinone) and PdCl2 (don't try to recover this, it is not worthwhile).

After filtration add 150 ml 10% HCl to hydrolyse the reaction to MDP2P, stirr for 15 minutes and now extract 3 times with 100 ml DCM, 50 ml and 25 ml DCM.

Combine extracts and wash them 2 times with 50 ml saturated sodiumbicarbonate solution, then 2 times with 50 ml saturated NaCl solution.

Then wash the extracts, which have now turned color a bit more greenish/yellow with 5-10% NaOH solution and do this 3 times with a volume of 100ml per wash, now dry the ketone after the NaOH solution has been drained off with MgSO4 or Na2SO4 (anhydrous).

And after it has been dried, distill off rotavap off the DCM and be left with impure MDP2P. This needs to be distilled and there are a few pictures of below:

This is the color of the MDP2P.

I've heard it smells like flowers, but I don't think it does, it doesn't even smell nice, it doesn't stink, but well, it's like safrole a bit, but then a bit more like flowers, then safrole, but not really like flowers, well anyway, smell it when you made it, and you know.

It has a greenish hue on it.

This is the reduction setup, but the same is the wacker oxidation since there is the safrole on the right and on the left the condenser for reflux and an overhead stirrer in the middle a heating mantle in the middle too, and in the back a bucket with 10 liters of cooling water.

After the MDP2P has distilled, one will have around 8 ml MDP2P to 15 ml.

SWIM got 8 ml it was the first time doing this reaction, but the yield will go up with more experience probably.

First, 4 ml MDP2P was reduced in a 500 ml round bottom flask with 8 g of Al foil, which has been put in the coffee bean grinder before and overhead stirring used etc. exactly like the picture above.

Enough MeOH was used to cover the Al and 60 mg HgCl2 was dissolved in 20 ml MeOH and added at once to the reaction through the dropping funnel, then after 15-20 minutes the amalgamation started, small bubbles occurred and then bigger ones, which is the point where the MDP2P needs to be added, but since the MDP2P, IF you will reduce it as it will only yield MDA (in acidic conditions), we want MDMA, so we add nitromethane (which will be reduced to methylamine in situ) and that forms an imine which then will be reduced to MDMA.

This is an BASIC Al/Hg reduction (reductive amination), when reducing nitropropene or styrene, then an acidic Al/Hg reduction is used with addition of example glacial acetic acid.

Methylamine is alkaline and will thus make the reaction basic.

Reduction going, make sure to add the MDP2P+MeNO2 at one drop per second, if you will drop everything in there at once one will get a very vigorous reaction, and you will be got drained in boiling MeOH and mercury etc., not very pleasant.

So use 4 ml MDP2P and 3,3 ml MeNO2 and 8 ml MeOH in the dropping funnel.

Look at the foam, this is how heavy the reaction is, here the Al is dissolving in the MeOH, due to the HgCl2, while it does this, it reduces the N-Methyl-MDP2P imine to MDMA.

When the reaction will cool down again, then add the MDP2P+MeNO2 faster, if you ran out of MDP2P+MeNO2, then start heating and reflux, until you reached 3 hours.

After 3 hours add NaOH solution (concentrated) and this is for the Al that hasn't dissolved, so which is left in the flask, this will heat up too and make the MeOH boil, anyway don't add the NaOH too quick, since then there it will also foam, and then it could also come out of the condenser.

So, after the addition of the NaOH, let it stir for 1 hour to make sure everything will dissolve.

Now you will have 2 layers a bottom layer with Al(OH)3 and probably black and an orange/yellow/red aqueous layer this it the layer you want to filtrate off the Al(OH)3 in a buchner (needs to be vacuumed), and then one will have something like this:

The filter, you might need to do the filtration in part, since the filter will clog up pretty much and even with strong vacuum you can t get it through anymore.

Anyway, first evaporate the MeOH from the reaction, then extract the remaining liquid with DCM 3 times (or any other non-polar solvent), SWIM just loves DCM since it rotavaps off really quick, anyway.

Then evaporate the DCM, then do an a/b or distill the MDMA freebase, SWIM normally prefers distillation but one needs a vacuum pump, which can pull below 10mbar for this job else the MDMA oil will decompose, so aspirator won't do.

Use the acid/base extraction, if you don't know what that is, you shouldn't be doing this synthesis.

In short, the MDMA oil can be an oil or a salt, the salt is water-soluble and the oil isn't.

You take advantage of this, right after the reaction when the oil is in the DCM, wash the DCM with water and NaCl solution and NaHCO3 solution, this takes out all the crap that does dissolve in water.

Then add H2SO4 to the oil after DCM evaporation (since then you see how much impure MDMA freebase you have), then add twice as much molar H2SO4 solution like 5%-15% solution, then add DCM and you can extract all the crap that does dissolve in non-polar solvents once again here, you can also use chloroform or toluene etc.

Now add NaOH to the water layer and do this with a NOT concentrated solution of NaOH.

Then you will see some white stuff when adding a bit of NaOH solution, this actually is the MDMA freebase, which, if you leave it, will settle to an oil layer on top of the water, but just do this and shake until the white cloudiness persist (means it doesn't go away anymore), then add DCM and add more, and shake everytime after every addition of 1-3 ml, and then when no more white cloudiness forms add the rest of the NaOH solution at once, until pH = 12-14.

Then drain off the DCM, keep it and extract the now basic aqueous mixture with 2 times more DCM and combine, evaporate DCM and you have pure MDMA freebase.

Enough MeOH was used to cover the Al and 60 mg HgCl2 was dissolved in 20 ml MeOH and added at once to the reaction through the dropping funnel, then after 15-20 minutes the amalgamation started, small bubbles occurred and then bigger ones, which is the point where the MDP2P needs to be added, but since the MDP2P, IF you will reduce it as it will only yield MDA (in acidic conditions), we want MDMA, so we add nitromethane (which will be reduced to methylamine in situ) and that forms an imine which then will be reduced to MDMA.

This is an BASIC Al/Hg reduction (reductive amination), when reducing nitropropene or styrene, then an acidic Al/Hg reduction is used with addition of example glacial acetic acid.

Methylamine is alkaline and will thus make the reaction basic.

Reduction going, make sure to add the MDP2P+MeNO2 at one drop per second, if you will drop everything in there at once one will get a very vigorous reaction, and you will be got drained in boiling MeOH and mercury etc., not very pleasant.

So use 4 ml MDP2P and 3,3 ml MeNO2 and 8 ml MeOH in the dropping funnel.

Look at the foam, this is how heavy the reaction is, here the Al is dissolving in the MeOH, due to the HgCl2, while it does this, it reduces the N-Methyl-MDP2P imine to MDMA.

When the reaction will cool down again, then add the MDP2P+MeNO2 faster, if you ran out of MDP2P+MeNO2, then start heating and reflux, until you reached 3 hours.

After 3 hours add NaOH solution (concentrated) and this is for the Al that hasn't dissolved, so which is left in the flask, this will heat up too and make the MeOH boil, anyway don't add the NaOH too quick, since then there it will also foam, and then it could also come out of the condenser.

So, after the addition of the NaOH, let it stir for 1 hour to make sure everything will dissolve.

Now you will have 2 layers a bottom layer with Al(OH)3 and probably black and an orange/yellow/red aqueous layer this it the layer you want to filtrate off the Al(OH)3 in a buchner (needs to be vacuumed), and then one will have something like this:

The filter, you might need to do the filtration in part, since the filter will clog up pretty much and even with strong vacuum you can t get it through anymore.

Anyway, first evaporate the MeOH from the reaction, then extract the remaining liquid with DCM 3 times (or any other non-polar solvent), SWIM just loves DCM since it rotavaps off really quick, anyway.

Then evaporate the DCM, then do an a/b or distill the MDMA freebase, SWIM normally prefers distillation but one needs a vacuum pump, which can pull below 10mbar for this job else the MDMA oil will decompose, so aspirator won't do.

Use the acid/base extraction, if you don't know what that is, you shouldn't be doing this synthesis.

In short, the MDMA oil can be an oil or a salt, the salt is water-soluble and the oil isn't.

You take advantage of this, right after the reaction when the oil is in the DCM, wash the DCM with water and NaCl solution and NaHCO3 solution, this takes out all the crap that does dissolve in water.

Then add H2SO4 to the oil after DCM evaporation (since then you see how much impure MDMA freebase you have), then add twice as much molar H2SO4 solution like 5%-15% solution, then add DCM and you can extract all the crap that does dissolve in non-polar solvents once again here, you can also use chloroform or toluene etc.

Now add NaOH to the water layer and do this with a NOT concentrated solution of NaOH.

Then you will see some white stuff when adding a bit of NaOH solution, this actually is the MDMA freebase, which, if you leave it, will settle to an oil layer on top of the water, but just do this and shake until the white cloudiness persist (means it doesn't go away anymore), then add DCM and add more, and shake everytime after every addition of 1-3 ml, and then when no more white cloudiness forms add the rest of the NaOH solution at once, until pH = 12-14.

Then drain off the DCM, keep it and extract the now basic aqueous mixture with 2 times more DCM and combine, evaporate DCM and you have pure MDMA freebase.

4,0 ml MDP2P yields with this method 3,0 ml exact MDMA freebase, which needs 1,95 ml of 29% HCl solution or 0,566 g HCl calculate your own amount for your concentration you have.

Just add the HCl solution, while the freebase is dissolved in toluene (dry).

Now you will have a little aqueous layer on the bottom of your little RBF, now put a dean&stark trap on top of the RBF or just attach it to a distillation setup, the point here is to distill off the water, the dean&stark trap breaks the azeotrope, which normally is formed with water, and thus drives off the water, anyway when the water evaporates the HCl salt of MDMA will then settle out as a brown paste or very viscous layer on the bottom, then after all the water and some toluene came over you add the double volume of acetone so for 3,0 ml MDMA freebase you use 10 ml toluene and 30 ml acetone (anhydrous) this sucks up the water that still is in there, and then the paste will turn into nice white crystals(the acetone also takes up some crap).

Now put in freezer overnight or a couple of hours and filtrate, and wash with acetone (anhydrous and cold).

Some pictures:

Tadaa 3000 mg MDMA.HCl

Just add the HCl solution, while the freebase is dissolved in toluene (dry).

Now you will have a little aqueous layer on the bottom of your little RBF, now put a dean&stark trap on top of the RBF or just attach it to a distillation setup, the point here is to distill off the water, the dean&stark trap breaks the azeotrope, which normally is formed with water, and thus drives off the water, anyway when the water evaporates the HCl salt of MDMA will then settle out as a brown paste or very viscous layer on the bottom, then after all the water and some toluene came over you add the double volume of acetone so for 3,0 ml MDMA freebase you use 10 ml toluene and 30 ml acetone (anhydrous) this sucks up the water that still is in there, and then the paste will turn into nice white crystals(the acetone also takes up some crap).

Now put in freezer overnight or a couple of hours and filtrate, and wash with acetone (anhydrous and cold).

Some pictures:

Tadaa 3000 mg MDMA.HCl

Last edited by a moderator: