G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,596

- Solutions

- 3

- Reaction score

- 2,623

- Points

- 113

- Deals

- 1

Introduction

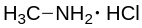

Many chemists are making a methylamine out of hexamine and HCl acid. I think it's very time-consuming and HCl is pretty nasty. Thus, I have found that one can easily make lots of good quality methylamine from ammonium chloride and formaldehyde (formalin). The only drawback with this method is that one must have good quality formaldehyde. It may have paraformaldehyde sediment in the bottom, it doesn't hurt, not even a bit, but Formaldehyde has to be strong and not some diluted shit, 35-40% is fine. Now to the more-less foolproof method. If you do like said below, you get around 600-750 g of pretty pure dimethylamine-free methylamine hydrochloride, which is perfect for Al/Hg reductive aminations.

Appearance: white powder;Boiling Point: 225-230 °C/15 mmHg;

Melting Point: 231-233 °C;

Molecular Weight: 67.52 g/mol.

Safety note: hold all manipulations in pull out probe or under exhaust hood; methylamine is a rather toxic substance, do not let its vapors enter the respiratory tract. Using respiratory mask is required. Inhalation of methylamine causes severe skin irritation, eyes and upper respiratory tract. Firstly, leads to excitement and then to depression of the central nervous system. Death can occur from respiratory arrest. Using chemical glass, gloves, chemical coat and respiratory mask is required.

Equipment and glassware:

- Three naked round bottom flasks 5 L x2;

- Round bottom flask with cap 5 L;

- Beakers 5 L x2, 2 L x2;

- Liebig condenser and water pump system (for condencer cooling) or water flow;

- Retort stand and clamp for securing apparatus;

- Connection tube;

- Distillation adapter with vacuum tap;

- Receiver flask 1 L;

- Laboratory grade thermometer (0 °C to 200 °C) with flask adapter;

- Conventional funnel for dry substances (d 15 cm) and liquids (d 15-20 cm);

- Laboratory scale (1 - 5000 g is suitable);

- Heater;

- Large Buchner funnel Ø 25 cm (or Shott filter) and flask 5 L;

- Pyrex dish 5 L;

- Water-jet aspirator;

- Ice bath (0 °C);

- Glass rod;

- Magnetic stirrer;

- Drying tube x2;

- Spatula;

- Vacuum desiccator (large);

- Paper filter.

Reagents:

- 4 kg (3711 ml, 47-53 moles) Technical formaldehyde (35-40 %; d 1.078 g/ml at 20 °C);

- 2 kg (37 moles) Technical ammonium chloride;

- ~1600 ml of absolute Ethanol or n-Butyl Alcohol.

Procedure

In a 5 liter three naked round bottom flasks, fitted with a stopper holding a condenser set for downward distillation and a thermometer which will extend well into the liquid, are placed 4 kg (3711 ml, 47-53 moles) of technical formaldehyde (35-40 %; d 1.078 g/ml at 20 °C) and 2 kg (37 moles) of technical ammonium chloride. The mixture is heated on the steam bath until no more distillate comes over and then over a flame until the temperature of the solution reaches 104 °C. At about 90 °C, an exothermic reaction kicks in (it needs to be cooled in a water bath once in a while at the beginning in order to keep temperature below 104-106 °C).

The temperature is held at this point until no more distillate comes over (four to six hours).

The distillate, which consists of by-products such as methylal (bp 42-43 °C), methylformate and water, which may be treated with NaOH solution to recover methylal (dimethoxymethane) and sodium formate. The contents of the reaction flask are cooled to room temp and the ammonium chloride which separates are filtered off on a large Buchner funnel. You should get a clear yellowish filtrate like in this picture.

The mother liquor (in three naked round bottom flasks 5 L) is concentrated on the steam bath under reduced pressure to 2500 ml, and again cooled to room temp, whereupon a second crop of ammonium chloride separates. The total recovery of ammonium chloride up to this point amounts to 780-815 g. The mother liquor is again concentrated under reduced pressure until crystals begin to form on the surface of the solution (1400-1500 ml). It is then cooled to room temperature, and a first crop of methylamine hydrochloride, containing some ammonium chloride, is obtained by filtering the cold solution. The Methylamine solutions in all steps should be cooled rapidly to promote smaller crystal formation. At this point, 625-660 g of crude product is obtained. The mother liquor is now concentrated under reduced pressure to about 1000 ml, and cooled, and a second crop of methylamine hydrochloride (170-190 g) is then filtered off. This crop of crystals is washed with 250 ml of cold chloroform, and filtered to remove most of the dimethylamine hydrochloride which is present. After the washing, the product weighs 140-150 g. The original mother liquor is then evaporated under reduced pressure, as far as possible, by heating on a steam bath, and the thick syrupy solution (about 350 ml) which remains are poured into a beaker and allowed to cool, with occasional stirring, in order to prevent the formation of a solid cake, and the crystals obtained are washed with 250 ml of cold chloroform, the solution is filtered yielding 55-65 g of product. There is no advantage in further concentrating the mother liquor, which contains mostly tetramethylmethylenediamine hydrochloride, but no trimethylamine hydrochloride. The total yield of methylamine hydrochloride is 830-850 g.

Purification

The product contains water, ammonium chloride and some dimethylamine hydrochloride. In order to obtain a pure product, the impure methylamine hydrochloride is recrystallized from absolute ethanol (solubility 0.6 g/100ml at 15 °C), or preferably butyl alcohol (even less soluble). Purification of the Methylamine HCl is in order now, so transfer all of the crude product to a 5 L rb flask and add either ~1600 ml of absolute Ethanol or, ideally, n-Butyl Alcohol. Heat at reflux with a Calcium Chloride dry tube for 30 minutes. Allow the undissolved solids to settle (Ammonium Chloride) then decant the clear solution through a paper filter and cool quickly to precipitate out Methylamine HCl. Filter rapidly on the vacuum Buchner funnel and transfer crystals to a vacuum desiccator. Repeat the reflux-settle-cool-filter process four more times if using absolute Ethanol, or two more times if using n-Butyl Alcohol. The recovery of ammonium chloride amounts to 100-150 grams, making the total recovery 850-950 g. The yield of recrystallized methylamine hydrochloride is 600-750 g (45-51% of theory, based on the used up ammonium chloride).

A standard run, from 250 g ammonium chloride and 500 g 37% formaldehyde (containing 15% methanol), gives 100-134 g methylamine hydrochloride, 27 grams dimethylamine hydrochloride and 81 grams of recovered ammonium chloride. The distillate contains methylal (formaldehyde dimethyl acetal) and methyl formate, which after treatment with NaOH can yield 25 g of sodium formate and 30 grams of methylal, as the compound cannot be separated by fractional distillation, neutralization is the way to go. Ammonium chloride is very sparingly soluble in a concentrated solution of methylammonium chloride, making the separation of the compounds pretty sharp.

A standard run, from 250 g ammonium chloride and 500 g 37% formaldehyde (containing 15% methanol), gives 100-134 g methylamine hydrochloride, 27 grams dimethylamine hydrochloride and 81 grams of recovered ammonium chloride. The distillate contains methylal (formaldehyde dimethyl acetal) and methyl formate, which after treatment with NaOH can yield 25 g of sodium formate and 30 grams of methylal, as the compound cannot be separated by fractional distillation, neutralization is the way to go. Ammonium chloride is very sparingly soluble in a concentrated solution of methylammonium chloride, making the separation of the compounds pretty sharp.

Last edited: