I had a failed first attempt and kinda fucked up big time by inhaling toxic fumes from the violent reaction.

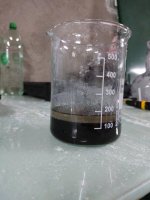

As I poured the P2NP solution into the flask, the funnel on the flask couldn't hold itself and started bouncing (simply because of vapor pressure from the reaction). It happened so quickly that I couldn't find any time to process what's happening and to put a condenser. As a result, I inhaled some toxic fumes from the reaction and I'm not exactly sure how toxic they were but it smelled so bad. Some solution got spilled as a result and the reactants got evaporated in the early stage.

The yield from my 10g setup was like 300mg of white salt(turned out it was some basic byproduct or unreacted amphemine freebase). It tasted like a soap and had a burning sensation so I threw it away. 5-6% yield was a red sign anyway.

Some mistakes that I made that newbies can avoid:

1. Don't use a small funnel on flask: When pouring the P2NP solution in the amalgam, make sure your funnel's stem is big enough (especially w/ a >=10g setup). Smaller stem/funnel size in general can be a bottleneck and cause spillage or other adverse outcomes (you have to be very quick here to add a condenser and shake the flask).

2. Make sure you don't evaporate the solvents in the P2NP+IPA+GAA solution while heating it. Sometimes P2NP crystals may not dissolve so gentle heating may help(40-50'C) but if you heat it more then solvents like IPA would begin to evaporate and you'd lose solvents.

3. Ensure that your water is distilled and has close to zero TDS. I bought some "destilled water" bottles but they turned out to be just purified water with a 25-30 TDS. It's not a significant issue but contaminated water should be avoided in the amalgam phase to avoid unnecessary reactions with water impurities.

4. Properly acidify the amphetamine freebase before proceeding for drying. My pH papers were shit so I couldn't measure properly but you shouldn't stop before a pH of 6. Keep adding more acid solution until you reach it. Mistakes at this stage can result in a basic soapy product, not amphetamine sulfate.

5. Extract your amphetamine freebase with a non-polar solvent. The video doesn't include this part but it's an important step to not miss if you want a successful and pure yield. Something like Toluene could work. I haven't tried this it before but next time I'm going to do this.

6. If it's your first time, be very careful with the exothermic reaction when adding P2NP solution to the amalgam. In reality it can be far more violent than what's shown in the video so be prepared for that. Proper PPE and preparation can help like keeping cold water and condenser handy.

I have a few questions here for the experienced chemists:

1. How to deal with solvents volume loss? Even after a condenser and ice-baths, sometimes it can evaporate more. At what stage are we safe to add some IPA to the mixture? The video descriptions says you can add some IPA after the reaction is complete(to rinse the flask). Is that correct and if yes, how much are we talking at this scale? 15-20ml?

2. Can we add the P2NP solution slowly and in batches instead of at once? I can see this can result in more solvent evaporation but I really want to avoid overheating and violent reaction.