GhostChemist

Expert

- Language

- 🇬🇧

- Joined

- Nov 20, 2022

- Messages

- 90

- Reaction score

- 224

- Points

- 33

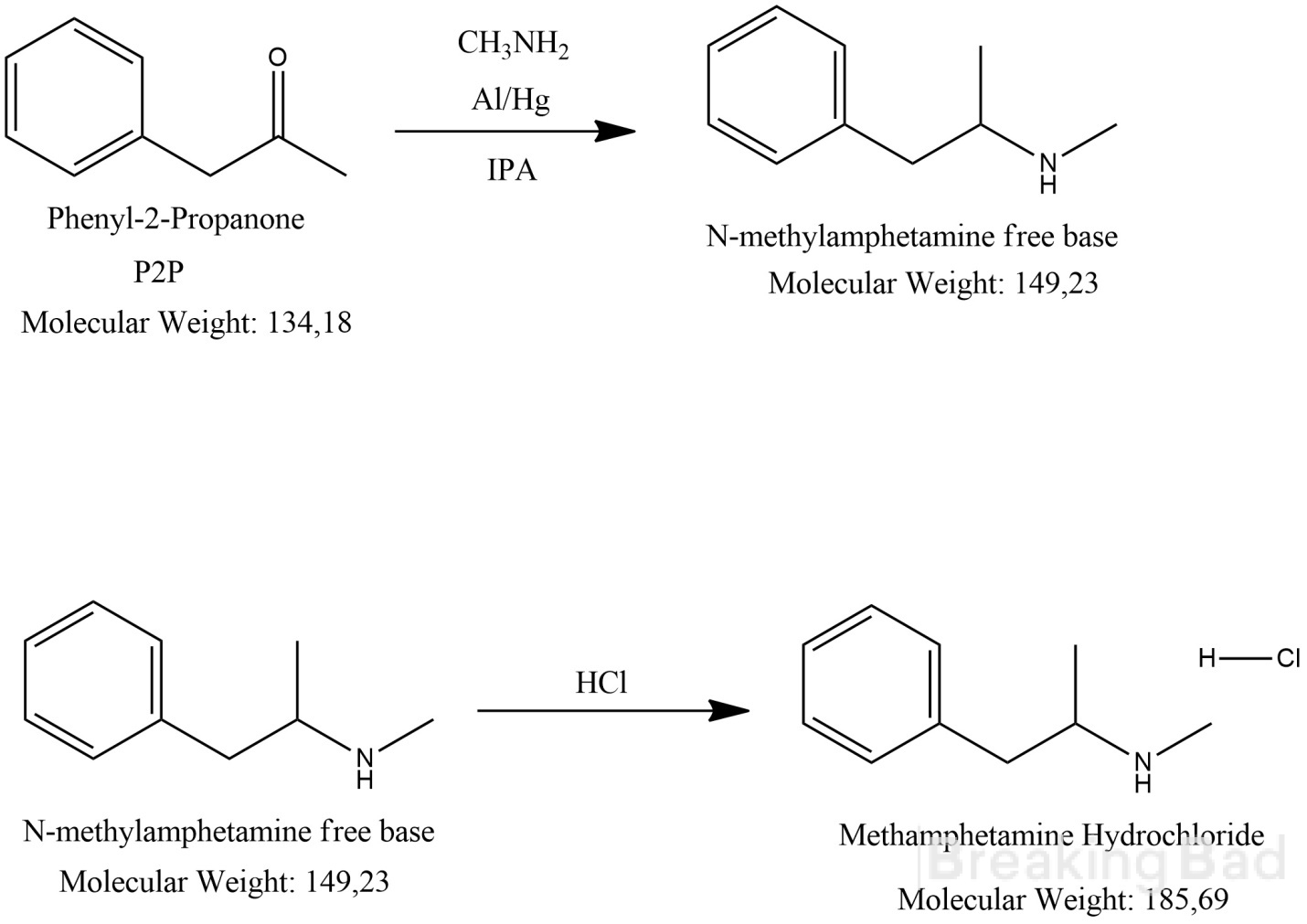

The reactions proceed according to the Scheme 1.

Active hydrogen evolution during the preparation of an amalgam. Fig 2

Methylamine, sodium chloride solution, p2p and ethanol are added to the prepared amalgam. A reflux condenser is connected. Fig 3

When the flask is strongly heated (above 40-50°C), cooling in an ice bath is necessary. Fig 4

Appearance of the reaction mixture inside the flask during the active progression of the process. Fig 5

Next, a sodium hydroxide solution is added to the reaction mixture to dissolve excess aluminum, and it is left for approximately 1 hour. The resulting reaction mixture is poured onto a filter without further washing of the sludge. Fig 6

The obtained amine solution is extracted with several portions of DCM (dichloromethane). Fig 7

The DCM layer is separated in a separating funnel. The separated DCM layer, if necessary, is filtered, dried with anhydrous sodium sulfate, and distilled to an oil at T=90°C.

The extract in DCM is distilled before distillation. Fig 8

Free base after distillation of DCM. Fig 9

Next, a stream of gaseous hydrogen chloride is passed into the solution of the amine in ethanol until a strong acidic reaction and the appearance of a pink color in the solution. The obtained solution is evaporated to crystallization. Hydrogen chloride is obtained by adding sulfuric acid to ammonium chloride.

Crystallization of the amine hydrochloride. Fig 10

The crystallized amine hydrochloride. Fig 11

The crystallized mass is washed with diethyl ether (5-10 ml), filtered, and dried. Fig 12

The yield without additional sludge washing was 4.5 g, or 65% of the theoretical yield.

The loss in the sludge is 0.5 g, or 7.2%.

Reagents and Materials:

- Aluminum foil 14 µm, 6 g

- Mercury(II) chloride, 0.05 g

- Distilled water, 2-3 liters

- P2P (from p2np via NaBH4 reduction and steam distill) 5 g

- Aqueous methylamine 39%, 15 ml

- Sodium chloride, 5 g in 15 ml water

- IPA (isopropyl alcohol) or ethanol, 100 ml

- DCM (dichloromethane) 75-100 ml

- Ammonium chloride, 50-100 g

- Concentrated sulfuric acid 80%, 20-25 ml

- Technical-grade water, 2 liters with 500 g of ice

- Anhydrous sodium sulfate, 20-30 g

- 5 ml 25% NaOH

- Diethyl ether, 5-10 ml

- 2-liter, 500 ml, 250 ml flasks

- 500 ml three-necked flask for generating hydrogen chloride

- Reflux condenser

- Setup for solvent distillation with a water bath

- Vacuum filtration setup

- Separatory funnel

- Silicone grease for grinding

- Filter paper

- Funnels

- Beakers

- Heater

Synthesis Procedure

A 2-liter flask is charged with aluminum foil and filled with water so that the foil is submerged beneath its layer. Dry mercury(II) chloride is added, and the mixture is vigorously stirred until active hydrogen evolution occurs and a dull appearance forms on the foil. Fig 1Active hydrogen evolution during the preparation of an amalgam. Fig 2

Methylamine, sodium chloride solution, p2p and ethanol are added to the prepared amalgam. A reflux condenser is connected. Fig 3

When the flask is strongly heated (above 40-50°C), cooling in an ice bath is necessary. Fig 4

Appearance of the reaction mixture inside the flask during the active progression of the process. Fig 5

Next, a sodium hydroxide solution is added to the reaction mixture to dissolve excess aluminum, and it is left for approximately 1 hour. The resulting reaction mixture is poured onto a filter without further washing of the sludge. Fig 6

The obtained amine solution is extracted with several portions of DCM (dichloromethane). Fig 7

The DCM layer is separated in a separating funnel. The separated DCM layer, if necessary, is filtered, dried with anhydrous sodium sulfate, and distilled to an oil at T=90°C.

The extract in DCM is distilled before distillation. Fig 8

Free base after distillation of DCM. Fig 9

Next, a stream of gaseous hydrogen chloride is passed into the solution of the amine in ethanol until a strong acidic reaction and the appearance of a pink color in the solution. The obtained solution is evaporated to crystallization. Hydrogen chloride is obtained by adding sulfuric acid to ammonium chloride.

Crystallization of the amine hydrochloride. Fig 10

The crystallized amine hydrochloride. Fig 11

The crystallized mass is washed with diethyl ether (5-10 ml), filtered, and dried. Fig 12

The yield without additional sludge washing was 4.5 g, or 65% of the theoretical yield.

The loss in the sludge is 0.5 g, or 7.2%.

Last edited by a moderator: