- Joined

- Jul 5, 2021

- Messages

- 710

- Solutions

- 1

- Reaction score

- 982

- Points

- 93

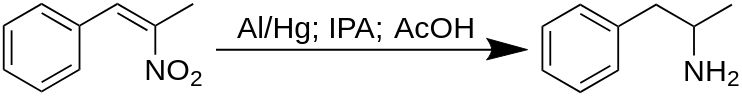

In the video synthesis of amphetamine, reagents are used:

Description of amphetamine synthesis video.

- 10 g 1-Phenyl-2-nitropropene (P2NP);

- 100 ml Isopropyl alcohol (IPA);

- 50 ml Glacial acetic acid (AcOH);

- 50 g Sodium hydroxide (NaOH);

- 12 g Aluminium (in the form of sliced household foil);

- 0.1g Mercury (II) nitrate (Hg(NO3)2);

- 2 ml Sulphuric acid (H2SO4);

- 50 ml Acetone;

- Distilled water;

- Flat bottom flask 2 L;

- Retort stand and clamp for securing apparatus (optional);

- Reflux condenser;

- Funnel;

- Sieve filter (kitchen grade is ok);

- Syringe or Pasteur pipette;

- pH indicator papers;

- Beakers (600 mL x2, 2 L, 1 L, 100 mL x2);

- Vacuum source;

- Laboratory scale (0.1-200 g is suitable);

- Measuring cylinders 1000 mL and 100 mL;

- Cold water bath;

- Glass rod and spatula;

- Separatory funnel 1 L (optional);

- Laboratory grade thermometer;

- Buchner flask and funnel;

- Filter paper;

Description of amphetamine synthesis video.

A solution of 1-phenyl-2-nitropropene 10 g in 100 ml of isopropyl alcohol and 50 ml of acetic acid is prepared before the synthesis start. Also, an aluminium foil 12 g is cut into small pieces with a paper shredder for an aluminium amalgam preparation. It can be cut with scissors or torn by hands (in gloves).

0:04-0:40 - An aqueous alkali solution of preparation. This solution was made in advance so that the solution has room temperature by the main reaction mixture alkalization time in this video. The alkalinization is carried out with a spontaneous heating. If a fresh hot aq alkali solution is used, then the temperature is risen higher and a reaction mass forced cooling will be required.

0:46-2:36 - Amalgam with mercury nitrate. Amalgamated aluminium will reduce 1-phenyl-2-nitropropene to amphetamine. A small amount of gas is evolved during the amalgamation reaction, a grey precipitate is formed. It is important not to miss the moment when the aluminium amalgam is ready. This moment can be determined by a grey precipitate formation and by an increased gas evolution. It happens in 10-15 minutes from reaction start.

The water is drained without a gauze removing, the amalgamated aluminium is washed with two portions of cold distilled water. It is worth to pay attention to a gas bubbles releasing. It is noticed that bubbles are smaller and liquid color is darker in a "correct" amalgam. If the reaction is violent, bubbles are large and the color is light, the amalgam is "incorrect". This is almost certainly due to a lack of mercury salt. Please note that mercury salts are poisonous.

2:37-4:28 - The most important part of the process is 1-phenyl-2-nitropropene reduction by aluminium amalgam. The reaction is exothermic and carried out with an abundant heat releasing. It is necessary to carefully control the temperature during the procedure. Reaction flask is cooled in an ice bath in case of overheating. It is allowed to add cold water into the flask. Sometimes the reaction isn't started, it is necessary to warm the reaction mass thoroughly and the reaction is started (with a properly prepared amalgam). Smells of a boiling alcohol and acetic acid are released during reaction. Allihn reflux condenser is used for a vapors capturing. The efficiency of Allihn reflux condenser can be increased by a running cold water, which can be connected to it.

5:04 - The reaction flask can be rinsed with a small amount of alcohol and unredacted aluminium can be rinsed with it as well for collecting residues and increasing the yield.

5:13 - There should be little unreacted aluminium left. You can determine an amount of reacted 1-phenyl-2-nitropropene by the residues.

5:16-6:13 - Alkalinization. The reaction is conducted with a heat releasing. The remains of unredacted aluminium will additionally react with alkali and heat the mixture as well as create by-products.

A separation into visible layers occurs within 30 minutes after alkalinization. The pH of the top layer should be 11-12.

6:18-7:23 - Decantation. Collect the top layer with amphetamine base in alcohol. It can be dried by a small amount of anhydrous magnesium sulfate. The slag can be extracted with a non-polar solvent (ether, benzene, toluene), then a solvent is evaporated.

7:24-8:50 - Preparation of the sulphuric acid solution in acetone. This solution is necessary for smoother acidification. If concentrated sulphuric acid is used, local over-acidification of the product is happened. Hence, the yield is dropping.

8:51-10:53 - Product acidification and amphetamine sulfate obtaining. To the upper yellow layer, which was collected at the previous stage, a prepared solution of sulphuric acid is added dropwise. Flakes of salt are formed with each drop of acid solution. This stage is very important, it is necessary to carefully control pH to avoid over-acidification. Acidification is continued until pH 5.5-6. The over-acidified product has pinkish color. The product will be spoiled in case of a total over-acidification.

10:55-11:38 - Amphetamine sulfate filtration from solvents in a Buchner funnel under vacuum. The product can be additionally rinsed with cold acetone at this stage by pouring it through Buchner funnel with the amphetamine sulphate cake.

11:41-12:28 - Filtration using improvised tools. Any thick fabric can be used as a filter. The resulting product is dried in a warm dry place for several hours to remove residual solvents. It is recommended to store it in a vacuum package.

The yield is 60-70%.

0:04-0:40 - An aqueous alkali solution of preparation. This solution was made in advance so that the solution has room temperature by the main reaction mixture alkalization time in this video. The alkalinization is carried out with a spontaneous heating. If a fresh hot aq alkali solution is used, then the temperature is risen higher and a reaction mass forced cooling will be required.

0:46-2:36 - Amalgam with mercury nitrate. Amalgamated aluminium will reduce 1-phenyl-2-nitropropene to amphetamine. A small amount of gas is evolved during the amalgamation reaction, a grey precipitate is formed. It is important not to miss the moment when the aluminium amalgam is ready. This moment can be determined by a grey precipitate formation and by an increased gas evolution. It happens in 10-15 minutes from reaction start.

The water is drained without a gauze removing, the amalgamated aluminium is washed with two portions of cold distilled water. It is worth to pay attention to a gas bubbles releasing. It is noticed that bubbles are smaller and liquid color is darker in a "correct" amalgam. If the reaction is violent, bubbles are large and the color is light, the amalgam is "incorrect". This is almost certainly due to a lack of mercury salt. Please note that mercury salts are poisonous.

2:37-4:28 - The most important part of the process is 1-phenyl-2-nitropropene reduction by aluminium amalgam. The reaction is exothermic and carried out with an abundant heat releasing. It is necessary to carefully control the temperature during the procedure. Reaction flask is cooled in an ice bath in case of overheating. It is allowed to add cold water into the flask. Sometimes the reaction isn't started, it is necessary to warm the reaction mass thoroughly and the reaction is started (with a properly prepared amalgam). Smells of a boiling alcohol and acetic acid are released during reaction. Allihn reflux condenser is used for a vapors capturing. The efficiency of Allihn reflux condenser can be increased by a running cold water, which can be connected to it.

5:04 - The reaction flask can be rinsed with a small amount of alcohol and unredacted aluminium can be rinsed with it as well for collecting residues and increasing the yield.

5:13 - There should be little unreacted aluminium left. You can determine an amount of reacted 1-phenyl-2-nitropropene by the residues.

5:16-6:13 - Alkalinization. The reaction is conducted with a heat releasing. The remains of unredacted aluminium will additionally react with alkali and heat the mixture as well as create by-products.

A separation into visible layers occurs within 30 minutes after alkalinization. The pH of the top layer should be 11-12.

6:18-7:23 - Decantation. Collect the top layer with amphetamine base in alcohol. It can be dried by a small amount of anhydrous magnesium sulfate. The slag can be extracted with a non-polar solvent (ether, benzene, toluene), then a solvent is evaporated.

7:24-8:50 - Preparation of the sulphuric acid solution in acetone. This solution is necessary for smoother acidification. If concentrated sulphuric acid is used, local over-acidification of the product is happened. Hence, the yield is dropping.

8:51-10:53 - Product acidification and amphetamine sulfate obtaining. To the upper yellow layer, which was collected at the previous stage, a prepared solution of sulphuric acid is added dropwise. Flakes of salt are formed with each drop of acid solution. This stage is very important, it is necessary to carefully control pH to avoid over-acidification. Acidification is continued until pH 5.5-6. The over-acidified product has pinkish color. The product will be spoiled in case of a total over-acidification.

10:55-11:38 - Amphetamine sulfate filtration from solvents in a Buchner funnel under vacuum. The product can be additionally rinsed with cold acetone at this stage by pouring it through Buchner funnel with the amphetamine sulphate cake.

11:41-12:28 - Filtration using improvised tools. Any thick fabric can be used as a filter. The resulting product is dried in a warm dry place for several hours to remove residual solvents. It is recommended to store it in a vacuum package.

The yield is 60-70%.

Last edited by a moderator:

↑View previous replies…

- Language

- 🇺🇸

- Joined

- Dec 7, 2024

- Messages

- 3

- Reaction score

- 0

- Points

- 1