Video amfetamīnasintēzē tiek izmantoti reaģenti:

Amfetamīna sintēzes video apraksts.

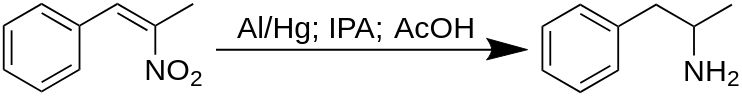

- 10 g 1-fenil-2-nitropropēna (P2NP);

- 100 ml izopropilspirta (IPA);

- 50 ml ledus etiķskābes (AcOH);

- 50 g nātrija hidroksīda (NaOH);

- 12 g alumīnija (sagrieztas sadzīves folijas veidā);

- 0,1 g dzīvsudraba (II) nitrāta (Hg(NO3)2);

- 2 ml sērskābes (H2SO4);

- 50 ml acetona;

- Destilēts ūdens;

- Kolba ar plakanu dibenu, 2 l;

- Retorta statīvs un skava aparāta nostiprināšanai (pēc izvēles);

- Atpakaļplūsmas kondensators;

- piltuve;

- sieta filtrs (der virtuves filtrs);

- Šļirce vai Pastēra pipete;

- pH indikatora papīriņi;

- spaiņi (600 ml x2, 2 L, 1 L, 100 ml x2);

- Vakuuma avots;

- Laboratorijas svari (piemēroti 0,1-200 g);

- Mērcilindri 1000 ml un 100 ml;

- Aukstā ūdens vanna;

- Stikla stienis un lāpstiņa;

- 1 L dalāmā piltuve (pēc izvēles);

- laboratorijas termometrs;

- Bihnera kolba un piltuve;

- filtrpapīrs;

Amfetamīna sintēzes video apraksts.

Pirms sintēzes sākuma sagatavo 10 g 1-fenil-2-nitropropēna šķīdumu 100 ml izopropilspirta un 50 ml etiķskābes. Alumīnija amalgamas pagatavošanai arpapīra smalcinātāju sagriež sīkos gabaliņos arī alumīnija foliju 12 g . To var sagriezt ar šķērēm vai pārgriezt ar rokām (cimdos).

0:04-0:40 - Preparāta ūdens sārma šķīdums. Šis šķīdums tika pagatavots iepriekš, lai šķīdumam būtu istabas temperatūra līdz galvenajam reakcijas maisījuma sārmošanas laikam šajā video. Sārmošanu veic ar spontānu sildīšanu. Ja izmanto svaigu karstu sārmu šķīdumu, tad temperatūra paaugstināsies un būs nepieciešama reakcijas masas piespiedu dzesēšana.

0:46-2:36 - Amalgama ar dzīvsudraba nitrātu. Amalgamētais alumīnijs reducē 1-fenil-2-nitropropēnu līdz amfetamīnam. Amalgamēšanas reakcijas laikā izdalās neliels gāzes daudzums, veidojas pelēkas nogulsnes. Ir svarīgi nepalaist garām brīdi, kad alumīnija amalgama ir gatava. Šo brīdi var noteikt pēc pelēko nogulšņu veidošanās un pastiprinātas gāzes izdalīšanās. Tas notiek 10 līdz 15 minūšu laikā no reakcijas sākuma.

Ūdens tiek izlaists bez marles noņemšanas, amalgamētais alumīnijs tiek izskalots ar divām porcijām auksta destilēta ūdens. Jāpievērš uzmanība gāzes burbuļu izdalīšanai. Novēro, ka "pareizā" amalgamā burbuļi ir mazāki un šķidruma krāsa ir tumšāka. Ja reakcija ir strauja, burbuļi ir lieli un krāsa ir gaiša, amalgama ir "nepareiza". Tas gandrīz noteikti ir saistīts ar dzīvsudraba sāls trūkumu. Ņemiet vērā, ka dzīvsudraba sāļi ir indīgi.

2:37-4:28 - Vissvarīgākā procesa daļa ir 1-fenil-2-nitropropēna reducēšana ar alumīnija amalgamu. Reakcija ir eksotermiska, un tā notiek, izdalot daudz siltuma. Procedūras laikā rūpīgi jākontrolē temperatūra. Reakcijas kolbu pārkaršanas gadījumā atdzesē ledus vannā. Kolbā drīkst pievienot aukstu ūdeni. Dažreiz reakcija netiek uzsākta, reakcijas masa kārtīgi jāsasilda un reakcija jāuzsāk (ar pareizi sagatavotu amalgamu). Reakcijas laikā izdalās verdoša spirta un etiķskābes smarža. Tvaiku uztveršanai izmanto Allihn atgaitas kondensatoru. Allihn pretplūsmas kondensatora efektivitāti var palielināt, ja tam pieslēdz tekošu aukstu ūdeni.

5:04 - Reakcijas kolbu var izskalot ar nelielu daudzumu spirta, un ar to var izskalot arī nereaģējušo alumīniju, lai savāktu atlikumus un palielinātu iznākumu.

5:13 - Nereaģējušajam alumīnijam jābūt maz. Pēc atlikumiem var noteikt reaģējušā 1-fenil-2-nitropropēna daudzumu.

5:16-6:13 - Sārmojums. Reakciju veic ar siltuma izdalīšanu. Nereaģējušā alumīnija atliekas papildus reaģē ar sārmu un maisījumu uzkarsē, kā arī rada blakusproduktus.

30 minūšu laikā pēc sārmošanas notiek atdalīšanās redzamos slāņos. Augšējā slāņa pH jābūt 11-12.

6:18-7:23 - Dekantēšana. Savāc virsējo slāni ar amfetamīna bāzi spirtā. To var izžāvēt ar nelielu daudzumu bezūdens magnija sulfāta. Šlakvielas var ekstrahēt ar nepolāru šķīdinātāju (ēteri, benzolu, toluolu), tad šķīdinātāju iztvaicē.

7:24-8:50 - Sērskābes šķīduma sagatavošana acetonā. Šis šķīdums ir nepieciešams vienmērīgākai paskābināšanai. Ja izmanto koncentrētu sērskābi, notiek vietēja produkta pārskābošanās. Tādējādi samazinās iznākums.

8:51-10: 53 - Produkta paskābināšana un amfetamīna sulfāta iegūšana. Augšējam dzeltenajam slānim, kas tika savākts iepriekšējā posmā, pilienveidā pievieno sagatavotu sērskābes šķīdumu. Ar katru pilienu skābes šķīduma veidojas sāls pārslas. Šis posms ir ļoti svarīgs, rūpīgi jākontrolē pH, lai izvairītos no pārskābes. Skābināšanu turpina līdz pH 5,5 - 6. Pārskābinātam produktam ir sārta krāsa. Pilnīgas pārskābes gadījumā produkts bojājas.

10:55-11:38 - Amfetamīna sulfāta filtrēšana no šķīdinātājiem Bihnera piltuvē vakuumā. Šajā posmā produktu var papildus noskalot ar aukstu acetonu, izlejot to caur Buknera piltuvi kopā ar amfetamīna sulfāta kūku.

11:41-12:28 - Filtrēšana, izmantojot improvizētus instrumentus. Par filtru var izmantot jebkuru biezu audumu. Iegūto produktu vairākas stundas žāvē siltā un sausā vietā, lai atdalītu šķīdinātāju atliekas. Ieteicams to uzglabāt vakuuma iepakojumā.

Ieguvums ir 60-70 %.

0:04-0:40 - Preparāta ūdens sārma šķīdums. Šis šķīdums tika pagatavots iepriekš, lai šķīdumam būtu istabas temperatūra līdz galvenajam reakcijas maisījuma sārmošanas laikam šajā video. Sārmošanu veic ar spontānu sildīšanu. Ja izmanto svaigu karstu sārmu šķīdumu, tad temperatūra paaugstināsies un būs nepieciešama reakcijas masas piespiedu dzesēšana.

0:46-2:36 - Amalgama ar dzīvsudraba nitrātu. Amalgamētais alumīnijs reducē 1-fenil-2-nitropropēnu līdz amfetamīnam. Amalgamēšanas reakcijas laikā izdalās neliels gāzes daudzums, veidojas pelēkas nogulsnes. Ir svarīgi nepalaist garām brīdi, kad alumīnija amalgama ir gatava. Šo brīdi var noteikt pēc pelēko nogulšņu veidošanās un pastiprinātas gāzes izdalīšanās. Tas notiek 10 līdz 15 minūšu laikā no reakcijas sākuma.

Ūdens tiek izlaists bez marles noņemšanas, amalgamētais alumīnijs tiek izskalots ar divām porcijām auksta destilēta ūdens. Jāpievērš uzmanība gāzes burbuļu izdalīšanai. Novēro, ka "pareizā" amalgamā burbuļi ir mazāki un šķidruma krāsa ir tumšāka. Ja reakcija ir strauja, burbuļi ir lieli un krāsa ir gaiša, amalgama ir "nepareiza". Tas gandrīz noteikti ir saistīts ar dzīvsudraba sāls trūkumu. Ņemiet vērā, ka dzīvsudraba sāļi ir indīgi.

2:37-4:28 - Vissvarīgākā procesa daļa ir 1-fenil-2-nitropropēna reducēšana ar alumīnija amalgamu. Reakcija ir eksotermiska, un tā notiek, izdalot daudz siltuma. Procedūras laikā rūpīgi jākontrolē temperatūra. Reakcijas kolbu pārkaršanas gadījumā atdzesē ledus vannā. Kolbā drīkst pievienot aukstu ūdeni. Dažreiz reakcija netiek uzsākta, reakcijas masa kārtīgi jāsasilda un reakcija jāuzsāk (ar pareizi sagatavotu amalgamu). Reakcijas laikā izdalās verdoša spirta un etiķskābes smarža. Tvaiku uztveršanai izmanto Allihn atgaitas kondensatoru. Allihn pretplūsmas kondensatora efektivitāti var palielināt, ja tam pieslēdz tekošu aukstu ūdeni.

5:04 - Reakcijas kolbu var izskalot ar nelielu daudzumu spirta, un ar to var izskalot arī nereaģējušo alumīniju, lai savāktu atlikumus un palielinātu iznākumu.

5:13 - Nereaģējušajam alumīnijam jābūt maz. Pēc atlikumiem var noteikt reaģējušā 1-fenil-2-nitropropēna daudzumu.

5:16-6:13 - Sārmojums. Reakciju veic ar siltuma izdalīšanu. Nereaģējušā alumīnija atliekas papildus reaģē ar sārmu un maisījumu uzkarsē, kā arī rada blakusproduktus.

30 minūšu laikā pēc sārmošanas notiek atdalīšanās redzamos slāņos. Augšējā slāņa pH jābūt 11-12.

6:18-7:23 - Dekantēšana. Savāc virsējo slāni ar amfetamīna bāzi spirtā. To var izžāvēt ar nelielu daudzumu bezūdens magnija sulfāta. Šlakvielas var ekstrahēt ar nepolāru šķīdinātāju (ēteri, benzolu, toluolu), tad šķīdinātāju iztvaicē.

7:24-8:50 - Sērskābes šķīduma sagatavošana acetonā. Šis šķīdums ir nepieciešams vienmērīgākai paskābināšanai. Ja izmanto koncentrētu sērskābi, notiek vietēja produkta pārskābošanās. Tādējādi samazinās iznākums.

8:51-10: 53 - Produkta paskābināšana un amfetamīna sulfāta iegūšana. Augšējam dzeltenajam slānim, kas tika savākts iepriekšējā posmā, pilienveidā pievieno sagatavotu sērskābes šķīdumu. Ar katru pilienu skābes šķīduma veidojas sāls pārslas. Šis posms ir ļoti svarīgs, rūpīgi jākontrolē pH, lai izvairītos no pārskābes. Skābināšanu turpina līdz pH 5,5 - 6. Pārskābinātam produktam ir sārta krāsa. Pilnīgas pārskābes gadījumā produkts bojājas.

10:55-11:38 - Amfetamīna sulfāta filtrēšana no šķīdinātājiem Bihnera piltuvē vakuumā. Šajā posmā produktu var papildus noskalot ar aukstu acetonu, izlejot to caur Buknera piltuvi kopā ar amfetamīna sulfāta kūku.

11:41-12:28 - Filtrēšana, izmantojot improvizētus instrumentus. Par filtru var izmantot jebkuru biezu audumu. Iegūto produktu vairākas stundas žāvē siltā un sausā vietā, lai atdalītu šķīdinātāju atliekas. Ieteicams to uzglabāt vakuuma iepakojumā.

Ieguvums ir 60-70 %.

Last edited by a moderator: