GhostChemist

Expert

- Joined

- Nov 20, 2022

- Messages

- 88

- Reaction score

- 181

- Points

- 33

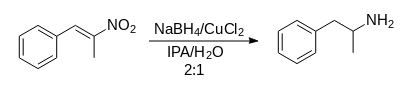

Reaction scheme:

Equipment and glassware:

Equipment and glassware:

Synthesis:

4. A solution of CuCl2 (105 g) in water (200 ml) is slowly added dropwise to keep the mixture temperature below 80 °С.

CuCl2 and CuCl2*2H2O

5. Thereafter, reaction is kept at 80 °C for 30 minutes with help of external heating.

6. A NaOH (8 liters 25%) water solution of is added to the reaction mixture and layers are separated.

7. The aqueous phase is extracted with 8 liters of IPA. Amphetamine free base is dissolved in IPA and IPA layer density is changed, hence, it is separated from aqueous layer.

8. The IPA from step 7 extract is evaporated on vacuum to an amphetamine free base oil and combined with free base from step 6.

9. The amphetamine free base oil is dissolved in 2 L of dry acetone.

10. Sulfuric acid (or orthophosphoric acid) is added dropwise to reach pH 6 (with a constant stirring).

11. Then, the mixture is put into a freezer for 12 hours.

12. After crystallization procedure in the freezer, the suspension of amphetamine salt is filtered with help of nutsche filter and washed with a dry cold acetone to white color. Acetone from washing procedure can be crystallized as described at steps 11-12 (amphetamine salt quality from this solution will be lower).

The reaction yield is 60-70 %.

- 50 L batch reactor with a reflux condenser, top stirrer and heating apparatus in a set-up;

- Drip funnel;

- Conventional funnel;

- Laboratory grade thermometer (up to 150 °С);

- Several buckets for 10 and 20 L;

- Measuring cylinder for 1 L;

- Vacuum source;

- Laboratory scale (1-2000 g is suitable);

- Cold water bath sours for reflux condenser;

- Nutsche filter;

- pH Indicator papers;

- 5 L x2 Beakers;

- Freezer;

- Pyrex dishes for crystallization;

- Isopropyl alcohol (IPA) 20 L;

- Distilled water 6.2 L;

- Sodium borohydride (NaBH4) 1739 g;

- P2NP (Phenyl-2-propanone) 1000 g;

- Copper (II) chloride (CuCl2) 105 g;

- Sodium hydroxide (NaOH) water solution 25% 8 L;

- Dry acetone 2.5 L;

- Sulfuric acid (or orthophosphoric acid);

1. A mixture of IPA and H2O 2:1 (18 liters) is added to a 50 L batch reactor.

2. Solid NaBH4 (1739 g) is added in one portion and stirrer is turned on.

3. Pure P2NP (1000 g) is added in several small portions to keep the mixture temperature below 60 °С.

2. Solid NaBH4 (1739 g) is added in one portion and stirrer is turned on.

3. Pure P2NP (1000 g) is added in several small portions to keep the mixture temperature below 60 °С.

4. A solution of CuCl2 (105 g) in water (200 ml) is slowly added dropwise to keep the mixture temperature below 80 °С.

CuCl2 and CuCl2*2H2O

5. Thereafter, reaction is kept at 80 °C for 30 minutes with help of external heating.

6. A NaOH (8 liters 25%) water solution of is added to the reaction mixture and layers are separated.

7. The aqueous phase is extracted with 8 liters of IPA. Amphetamine free base is dissolved in IPA and IPA layer density is changed, hence, it is separated from aqueous layer.

8. The IPA from step 7 extract is evaporated on vacuum to an amphetamine free base oil and combined with free base from step 6.

9. The amphetamine free base oil is dissolved in 2 L of dry acetone.

10. Sulfuric acid (or orthophosphoric acid) is added dropwise to reach pH 6 (with a constant stirring).

11. Then, the mixture is put into a freezer for 12 hours.

12. After crystallization procedure in the freezer, the suspension of amphetamine salt is filtered with help of nutsche filter and washed with a dry cold acetone to white color. Acetone from washing procedure can be crystallized as described at steps 11-12 (amphetamine salt quality from this solution will be lower).

The reaction yield is 60-70 %.

Last edited by a moderator: