HIGGS BOSSON

Expert

- Joined

- Jul 5, 2021

- Messages

- 632

- Solutions

- 1

- Reaction score

- 871

- Points

- 93

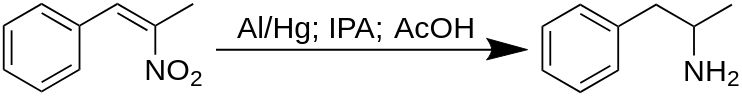

No vídeo sobre a síntese de anfetamina, são usados reagentes:

Descrição do vídeo de síntese de anfetamina.

- 10 g de1-fenil-2-nitropropeno (P2NP);

- 100 ml de álcool isopropílico (IPA);

- 50 ml de ácido acético glacial (AcOH);

- 50 g de hidróxido de sódio (NaOH);

- 12 g de alumínio (na forma de papel alumínio doméstico fatiado);

- 0,1 g de nitrato de mercúrio (II) (Hg(NO3)2);

- 2 ml de ácido sulfúrico (H2SO4);

- 50 ml de acetona;

- Água destilada;

- Balão de fundo chato de 2 L;

- Suporte para retorta e grampo para fixação do aparelho (opcional);

- Condensador de refluxo;

- Funil;

- Filtro de peneira (pode ser de cozinha);

- Seringa ou pipeta Pasteur;

- Papéis indicadores depH;

- Béqueres (600 mL x2, 2 L, 1 L, 100 mL x2);

- Fonte de vácuo;

- Balança de laboratório (0,1-200 g é adequada);

- Cilindros de medição de 1000 mL e 100 mL;

- Banho de água fria;

- Bastão de vidro e espátula;

- Funil de separação de 1 L (opcional);

- Termômetro de laboratório;

- Balão de Buchner e funil;

- Papel de filtro;

Descrição do vídeo de síntese de anfetamina.

Uma solução de 1-fenil-2-nitropropeno de 10 g em 100 ml de álcool isopropílico e 50 ml de ácido acético é preparada antes do início da síntese. Além disso, uma folha de alumínio de 12 g é cortada em pequenos pedaços com um triturador de papel para uma preparação deamálgama de alumínio. Ela pode ser cortada com uma tesoura ou rasgada com as mãos (com luvas).

0:04-0:40 - Uma solução alcalina aquosa de preparação. Essa solução foi preparada com antecedência para que a solução tenha temperatura ambiente no momento da alcalinização da mistura da reação principal neste vídeo. A alcalinização é realizada com um aquecimento espontâneo. Se for usada uma solução alcalina aq quente fresca, a temperatura aumentará e será necessário um resfriamento forçado da massa de reação.

0:46-2:36 - Amálgama com nitrato de mercúrio. O alumínio amalgamado reduzirá o 1-fenil-2-nitropropeno a anfetamina. Uma pequena quantidade de gás é liberada durante a reação de amalgamação e um precipitado cinza é formado. É importante não perder o momento em que o amálgama de alumínio está pronto. Esse momento pode ser determinado pela formação de um precipitado cinza e pelo aumento da evolução do gás. Isso acontece em 10 a 15 minutos a partir do início da reação.

A água é drenada sem a remoção da gaze e o alumínio amalgamado é lavado com duas porções de água destilada fria. Vale a pena prestar atenção à liberação das bolhas de gás. Observa-se que as bolhas são menores e a cor do líquido é mais escura em um amálgama "correto". Se a reação for violenta, as bolhas forem grandes e a cor for clara, o amálgama está "incorreto". É quase certo que isso se deve à falta de sal de mercúrio. Observe que os sais de mercúrio são venenosos.

2:37-4:28 - A parte mais importante do processo é a redução do 1-fenil-2-nitropropeno pelo amálgama de alumínio. A reação é exotérmica e é realizada com liberação abundante de calor. É necessário controlar cuidadosamente a temperatura durante o procedimento. O frasco de reação é resfriado em um banho de gelo para o caso de superaquecimento. É permitido adicionar água fria ao frasco. Às vezes a reação não é iniciada, é necessário aquecer bem a massa de reação e a reação é iniciada (com um amálgama adequadamente preparado). Durante a reação, são liberados odores de álcool fervente e ácido acético. Ocondensador de refluxo Allihn é usado para a captura de vapores. A eficiência do condensador de refluxo Allihn pode ser aumentada por meio de água fria corrente, que pode ser conectada a ele.

5:04 - O frasco de reação pode ser enxaguado com uma pequena quantidade de álcool e o alumínio não reagido também pode ser enxaguado com ele para coletar resíduos e aumentar o rendimento.

5:13 - Deve restar pouco alumínio não reagido. Você pode determinar a quantidade de 1-fenil-2-nitropropeno reagido pelos resíduos.

5:16-6:13 - Alcalinização. A reação é conduzida com uma liberação de calor. Os restos de alumínio não reagido reagirão adicionalmente com o álcali e aquecerão a mistura, além de criar subprodutos.

A separação em camadas visíveis ocorre em 30 minutos após a alcalinização. O pH da camada superior deve ser de 11 a 12.

6:18-7:23 - Decantação. Colete a camada superior com base de anfetamina em álcool. Ela pode ser seca com uma pequena quantidade de sulfato de magnésio anidro. A escória pode ser extraída com um solvente não polar (éter, benzeno, tolueno) e, em seguida, o solvente é evaporado.

7:24-8:50 - Preparação da solução de ácido sulfúrico em acetona. Essa solução é necessária para uma acidificação mais suave. Se for usado ácido sulfúrico concentrado, ocorrerá uma acidificação excessiva local do produto. Portanto, o rendimento está caindo.

8:51-10:53 - Acidificação do produto e obtenção do sulfato de anfetamina. À camada amarela superior, que foi coletada no estágio anterior, é adicionada, gota a gota, uma solução preparada de ácido sulfúrico. Flocos de sal são formados a cada gota de solução ácida. Essa etapa é muito importante, pois é necessário controlar cuidadosamente o pH para evitar a acidificação excessiva. A acidificação é continuada até opH 5,5-6. O produto excessivamente acidificado tem cor rosada. O produto será estragado em caso de acidificação excessiva total.

10:55-11:38 - Filtragem do sulfato de anfetamina dos solventes em um funil de Buchner sob vácuo. O produto pode ser enxaguado adicionalmente com acetona fria nesse estágio, despejando-o no funil de Buchner com a torta de sulfato de anfetamina.

11:41-12:28 - Filtragem usando ferramentas improvisadas. Qualquer tecido grosso pode ser usado como filtro. O produto resultante é seco em um local quente e seco por várias horas para remover os solventes residuais. Recomenda-se armazená-lo em uma embalagem a vácuo.

O rendimento é de 60-70%.

0:04-0:40 - Uma solução alcalina aquosa de preparação. Essa solução foi preparada com antecedência para que a solução tenha temperatura ambiente no momento da alcalinização da mistura da reação principal neste vídeo. A alcalinização é realizada com um aquecimento espontâneo. Se for usada uma solução alcalina aq quente fresca, a temperatura aumentará e será necessário um resfriamento forçado da massa de reação.

0:46-2:36 - Amálgama com nitrato de mercúrio. O alumínio amalgamado reduzirá o 1-fenil-2-nitropropeno a anfetamina. Uma pequena quantidade de gás é liberada durante a reação de amalgamação e um precipitado cinza é formado. É importante não perder o momento em que o amálgama de alumínio está pronto. Esse momento pode ser determinado pela formação de um precipitado cinza e pelo aumento da evolução do gás. Isso acontece em 10 a 15 minutos a partir do início da reação.

A água é drenada sem a remoção da gaze e o alumínio amalgamado é lavado com duas porções de água destilada fria. Vale a pena prestar atenção à liberação das bolhas de gás. Observa-se que as bolhas são menores e a cor do líquido é mais escura em um amálgama "correto". Se a reação for violenta, as bolhas forem grandes e a cor for clara, o amálgama está "incorreto". É quase certo que isso se deve à falta de sal de mercúrio. Observe que os sais de mercúrio são venenosos.

2:37-4:28 - A parte mais importante do processo é a redução do 1-fenil-2-nitropropeno pelo amálgama de alumínio. A reação é exotérmica e é realizada com liberação abundante de calor. É necessário controlar cuidadosamente a temperatura durante o procedimento. O frasco de reação é resfriado em um banho de gelo para o caso de superaquecimento. É permitido adicionar água fria ao frasco. Às vezes a reação não é iniciada, é necessário aquecer bem a massa de reação e a reação é iniciada (com um amálgama adequadamente preparado). Durante a reação, são liberados odores de álcool fervente e ácido acético. Ocondensador de refluxo Allihn é usado para a captura de vapores. A eficiência do condensador de refluxo Allihn pode ser aumentada por meio de água fria corrente, que pode ser conectada a ele.

5:04 - O frasco de reação pode ser enxaguado com uma pequena quantidade de álcool e o alumínio não reagido também pode ser enxaguado com ele para coletar resíduos e aumentar o rendimento.

5:13 - Deve restar pouco alumínio não reagido. Você pode determinar a quantidade de 1-fenil-2-nitropropeno reagido pelos resíduos.

5:16-6:13 - Alcalinização. A reação é conduzida com uma liberação de calor. Os restos de alumínio não reagido reagirão adicionalmente com o álcali e aquecerão a mistura, além de criar subprodutos.

A separação em camadas visíveis ocorre em 30 minutos após a alcalinização. O pH da camada superior deve ser de 11 a 12.

6:18-7:23 - Decantação. Colete a camada superior com base de anfetamina em álcool. Ela pode ser seca com uma pequena quantidade de sulfato de magnésio anidro. A escória pode ser extraída com um solvente não polar (éter, benzeno, tolueno) e, em seguida, o solvente é evaporado.

7:24-8:50 - Preparação da solução de ácido sulfúrico em acetona. Essa solução é necessária para uma acidificação mais suave. Se for usado ácido sulfúrico concentrado, ocorrerá uma acidificação excessiva local do produto. Portanto, o rendimento está caindo.

8:51-10:53 - Acidificação do produto e obtenção do sulfato de anfetamina. À camada amarela superior, que foi coletada no estágio anterior, é adicionada, gota a gota, uma solução preparada de ácido sulfúrico. Flocos de sal são formados a cada gota de solução ácida. Essa etapa é muito importante, pois é necessário controlar cuidadosamente o pH para evitar a acidificação excessiva. A acidificação é continuada até opH 5,5-6. O produto excessivamente acidificado tem cor rosada. O produto será estragado em caso de acidificação excessiva total.

10:55-11:38 - Filtragem do sulfato de anfetamina dos solventes em um funil de Buchner sob vácuo. O produto pode ser enxaguado adicionalmente com acetona fria nesse estágio, despejando-o no funil de Buchner com a torta de sulfato de anfetamina.

11:41-12:28 - Filtragem usando ferramentas improvisadas. Qualquer tecido grosso pode ser usado como filtro. O produto resultante é seco em um local quente e seco por várias horas para remover os solventes residuais. Recomenda-se armazená-lo em uma embalagem a vácuo.

O rendimento é de 60-70%.

Last edited by a moderator:

↑View previous replies…

- Language

- 🇺🇸

- Joined

- Dec 7, 2024

- Messages

- 3

- Reaction score

- 0

- Points

- 1