WillD

Expert

- Joined

- Jul 19, 2021

- Messages

- 685

- Reaction score

- 969

- Points

- 93

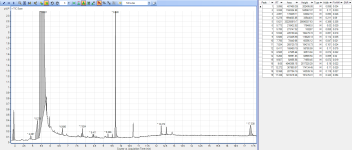

Reaction scheme:

Reagents:

1. 4'-Methylpropiophenone (cas 5337-93-9) 1 kg;

2. Hydrobromic acid 48% 1300 ml;

3. Hydrogen peroxide 35% 750 ml;

4. Sodium/potassium hydroxide 25% (NaOH/KOH) aqueous solution;

5. Distilled water;

6. Ethyl acetate 6 l;

7. Methylamine 40% aq - 2 l;

8. Acetone - 8 l;

9. Hydrochloric acid (HCl 38%) 500 ml;

10. Isopropyl alcohol;

Equipment and glassware:

1. Scales;

2. Jacketed 10 L reactor equipped with reflux condenser, drip funnel, thermometer, top stirrer and temperature control system;

3. Heating pump;

3. Chiller pump;

4. Vacuum source;

5. Buckets;

6. Freezer;

7. Pyrex dishes;

8. Nutsche filter;

9. pH indicator papers;

Stage 1. Halogenation

3. Hydrogen peroxide 750 g 35% is added into a drip funnel 1 l.

4. Hydrogen peroxide is added dropwise to the stirred reaction mixture.

5. Bromine is released during hydrogen peroxide addition to the mixture, dissolved in solution and reacted.

6. Hydrogen peroxide must be added at an appropriate rate so that the reaction mixture becomes colorless.

7. Reaction mixture temperature have to be kept less than 65 °C. An external cooling is applied in case of overheating. If reaction temperature is higher, hydrogen peroxide addition is stopped.

8. The second part of discoloration reaction can be conducted for longer time. Hydrogen peroxide is added according with reaction temperature.

9. Reaction mixture is left for a 12 h with a constant stirring at room temperature as soon as all hydrogen peroxide is added.

10. After 12 h precipitate is formed.

11. Sodium bicarbonate aq solution is added to the reaction mixture to reach neutral pH 6-7, stir it well. The mixture with 2-bromo-4'-methylpropiophenone is filtered through a Buchner funnel. Product is washed with small amount of distilled water.

12. Crude 2-bromo-4'-methylpropiophenone (cas 1451-82-7) is used for further reactions. Theoretical yield up to 1530 g. Practice yield is almost quantitative (video yield 94%).

Stage 2. Methamination.

1. Ethyl acetate 6 l is poured into the reactor.

1. Ethyl acetate 6 l is poured into the reactor.

2. Reaction mixture is stirred and heated in Jacketed reactor up to 30 °C with help of heating system.

3. The mixture is stirred until complete amount of 2-bromo-4'-methylpropiophenone (cas 1451-82-7) is dissolved.

4. The stirring is stopped. The reaction mixture is left for layer separations. A bottom layer is drained through a bottom reactor tap.

5. The stirrer is turned on and methylamine 40% aq 2 l is added at once.

6. The mixture is stirred for 20 min, temperature is kept below 65 °C.

7. Repeat step 4.

8. After that, the mixture is heated up to 55 °C and reactor vacuum pump is turned on. The reactor condenser chiller pump is turned on as well.

9. All amount of ethyl acetate or the biggest part of it is distilled off.

10. Vacuum pump is turned off. Acetone is added to the reactor with a constant stirring.

11. Hydrochloric acid (500 ml) is placed into the drip funnel and the funnel is installed onto the reactor neck.

12. Hydrochloric acid is added dropwise to reach pH 5 with constant stirring. A small amount (~2-5 ml) of reaction mixture is drained from the bottom reactor tap in order to check pH by pH indicator stripe. The sample is poured back into the reaction mixture.

13. After that, the mixture is poured into a bucket and the bucket is put into a freezer for 12 h.

Stage 3. Filtration.

1. A vacuum filtration system (Nutsche filter, filter cloth, vacuum pump) is assembled and installed.

2. The vacuum pump is turned on.

3. A bucket content from step 13 stage 2 is poured to the Nutsche filter.

4. The mixture is filtered and pressed until the funnel content is become solid.

5. A cold dry acetone is poured onto the solid product in the funnel in several small portions during filtration.

6. Acetone is filtered. Step 5 is repeated, if the solid is not white.

7. White solid 4-MMC product is moved into a Pyrex dish for a drying after filtration procedure.

8. Pyrex dish with 4-MMC is placed into a dry well ventilated warm room.

9. 4-MMC product is dried to a constant mass. Product is mixed and grinded periodically in order to increase drying speed.

Stage 4. Recrystallisation.

Mephedrone (4MMC) crystallization

Reagents:

1. 4'-Methylpropiophenone (cas 5337-93-9) 1 kg;

2. Hydrobromic acid 48% 1300 ml;

3. Hydrogen peroxide 35% 750 ml;

4. Sodium/potassium hydroxide 25% (NaOH/KOH) aqueous solution;

5. Distilled water;

6. Ethyl acetate 6 l;

7. Methylamine 40% aq - 2 l;

8. Acetone - 8 l;

9. Hydrochloric acid (HCl 38%) 500 ml;

10. Isopropyl alcohol;

Equipment and glassware:

1. Scales;

2. Jacketed 10 L reactor equipped with reflux condenser, drip funnel, thermometer, top stirrer and temperature control system;

3. Heating pump;

3. Chiller pump;

4. Vacuum source;

5. Buckets;

6. Freezer;

7. Pyrex dishes;

8. Nutsche filter;

9. pH indicator papers;

Stage 1. Halogenation

1. 4'-Methylpropiophenone 1000 g is added into a 10 L reactor flask.

2. Hydrobromic (HBr) acid 1300 g 48% is poured into the flask and stirred for 5 min.3. Hydrogen peroxide 750 g 35% is added into a drip funnel 1 l.

4. Hydrogen peroxide is added dropwise to the stirred reaction mixture.

5. Bromine is released during hydrogen peroxide addition to the mixture, dissolved in solution and reacted.

6. Hydrogen peroxide must be added at an appropriate rate so that the reaction mixture becomes colorless.

7. Reaction mixture temperature have to be kept less than 65 °C. An external cooling is applied in case of overheating. If reaction temperature is higher, hydrogen peroxide addition is stopped.

8. The second part of discoloration reaction can be conducted for longer time. Hydrogen peroxide is added according with reaction temperature.

9. Reaction mixture is left for a 12 h with a constant stirring at room temperature as soon as all hydrogen peroxide is added.

10. After 12 h precipitate is formed.

11. Sodium bicarbonate aq solution is added to the reaction mixture to reach neutral pH 6-7, stir it well. The mixture with 2-bromo-4'-methylpropiophenone is filtered through a Buchner funnel. Product is washed with small amount of distilled water.

12. Crude 2-bromo-4'-methylpropiophenone (cas 1451-82-7) is used for further reactions. Theoretical yield up to 1530 g. Practice yield is almost quantitative (video yield 94%).

13. The resulting product is left in the reactor.

Stage 2. Methamination.

2. Reaction mixture is stirred and heated in Jacketed reactor up to 30 °C with help of heating system.

3. The mixture is stirred until complete amount of 2-bromo-4'-methylpropiophenone (cas 1451-82-7) is dissolved.

4. The stirring is stopped. The reaction mixture is left for layer separations. A bottom layer is drained through a bottom reactor tap.

5. The stirrer is turned on and methylamine 40% aq 2 l is added at once.

6. The mixture is stirred for 20 min, temperature is kept below 65 °C.

7. Repeat step 4.

8. After that, the mixture is heated up to 55 °C and reactor vacuum pump is turned on. The reactor condenser chiller pump is turned on as well.

9. All amount of ethyl acetate or the biggest part of it is distilled off.

10. Vacuum pump is turned off. Acetone is added to the reactor with a constant stirring.

11. Hydrochloric acid (500 ml) is placed into the drip funnel and the funnel is installed onto the reactor neck.

12. Hydrochloric acid is added dropwise to reach pH 5 with constant stirring. A small amount (~2-5 ml) of reaction mixture is drained from the bottom reactor tap in order to check pH by pH indicator stripe. The sample is poured back into the reaction mixture.

13. After that, the mixture is poured into a bucket and the bucket is put into a freezer for 12 h.

Stage 3. Filtration.

1. A vacuum filtration system (Nutsche filter, filter cloth, vacuum pump) is assembled and installed.

2. The vacuum pump is turned on.

3. A bucket content from step 13 stage 2 is poured to the Nutsche filter.

4. The mixture is filtered and pressed until the funnel content is become solid.

5. A cold dry acetone is poured onto the solid product in the funnel in several small portions during filtration.

6. Acetone is filtered. Step 5 is repeated, if the solid is not white.

7. White solid 4-MMC product is moved into a Pyrex dish for a drying after filtration procedure.

8. Pyrex dish with 4-MMC is placed into a dry well ventilated warm room.

9. 4-MMC product is dried to a constant mass. Product is mixed and grinded periodically in order to increase drying speed.

Stage 4. Recrystallisation.

Mephedrone (4MMC) crystallization

Last edited by a moderator: